- Product Details

- {{item.text}}

Quick Details

-

MF:

-

-

-

EINECS No.:

-

-

-

Place of Origin:

-

China

-

Brand Name:

-

SIMEL

-

Model Number:

-

SM

-

Application:

-

plastics, coatings, adhesives and synthetic fibers.

-

Water solubility:

-

insoluble

Quick Details

-

CAS No.:

-

9003-35-4

-

Purity:

-

99

-

Other Names:

-

phenolic resin

-

MF:

-

-

-

EINECS No.:

-

-

-

Place of Origin:

-

China

-

Brand Name:

-

SIMEL

-

Model Number:

-

SM

-

Application:

-

plastics, coatings, adhesives and synthetic fibers.

-

Water solubility:

-

insoluble

Products Description

Chemical Name

:thermoplastic p-t-butyl pheno l-formaldehyde resin

Phenolic resin of bonded abrasive material series

There are the powder and liquid resin for bonded abrasives production to meet the demand of different domain. This series is adopted advanced production equipment and processing. With strict formula design, effective molecular weight and distributing control method, it makes the distributing of resin molecular reach an extremely ideal status. The powder resin is characterized in strong viscosity, mechanical strength, abrasion resistance, heat resistance and wet grinding stability. As the excellent wetter, the liquid resin has a good wetting function and well-distributed miscibility. It makes the liquid resin with good humidity by the special processing. There is no caking under the high humid environment and with high intensity and good grindability, which is the excellent product for grinding wheel.

There are the powder and liquid resin for bonded abrasives production to meet the demand of different domain. This series is adopted advanced production equipment and processing. With strict formula design, effective molecular weight and distributing control method, it makes the distributing of resin molecular reach an extremely ideal status. The powder resin is characterized in strong viscosity, mechanical strength, abrasion resistance, heat resistance and wet grinding stability. As the excellent wetter, the liquid resin has a good wetting function and well-distributed miscibility. It makes the liquid resin with good humidity by the special processing. There is no caking under the high humid environment and with high intensity and good grindability, which is the excellent product for grinding wheel.

|

ITEM

|

SPECIFICATION

|

|

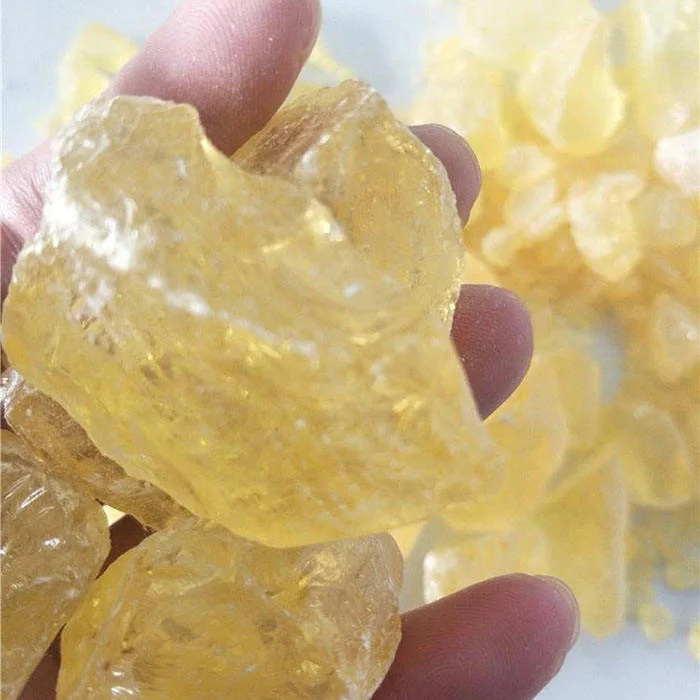

Appearance

|

Light yellow transparent solid

|

|

Softening point

|

85-115

|

|

Hydroxymethyl content, %

|

9-15

|

|

Free pheno l,% ≤

|

0.5

|

|

Ash content, % ≤

|

0.3

|

|

Acid value, mgKOH/g

|

50

|

Application

Application

:

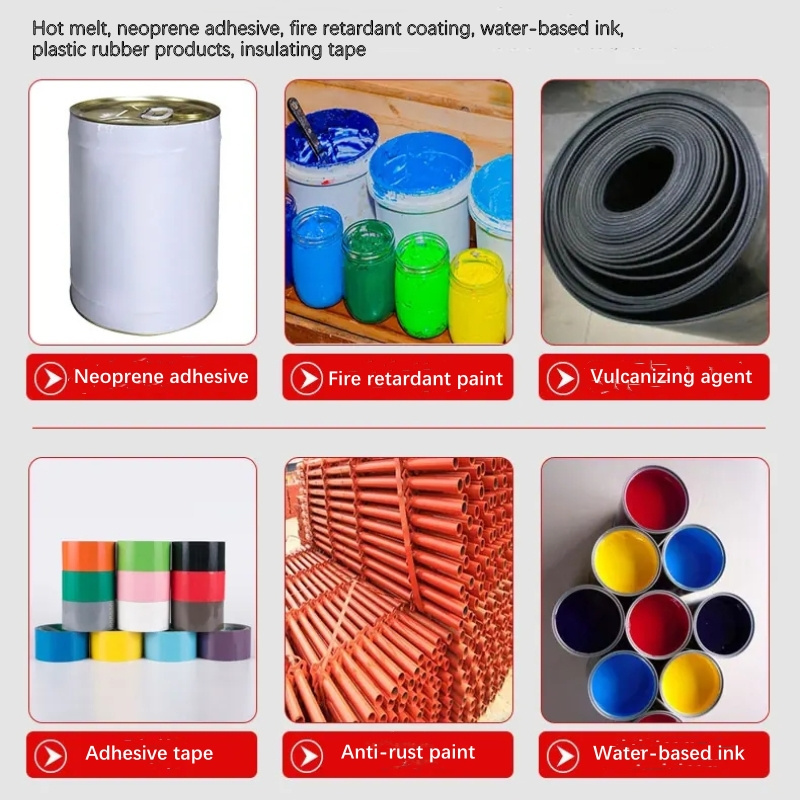

1.Pheno l-formaldehyde resin 2402 is a curing agent for rubber such as butyl rubber, natural rubber, styrene-butadiene rubber

(SBR), silico-butadiene rubber, especially applicable to sulfurizing butyl rubber.

2. It can be used to produce chloroprene rubber adhesive, with good compatibility with chloroprene adhesive. It is especially

applicable to the adhesive for shoes.

3.In coating industry, it can be used to produce end coating for external use, lacquer for floor, marine coating, antirust paint,

water based printing ink, and can be used as material of thin film anti-rust oil products.

4. It can be used both as sulfidizer, intensifier and tackifier when producing terylene adhesive tape, oil pipe anti-corrosive

adhesive and adhesive tape, etc, to improve the properties and extent the service period of products.

The effect will be even better if using 2402 resin together with terpene resin.

1.Pheno l-formaldehyde resin 2402 is a curing agent for rubber such as butyl rubber, natural rubber, styrene-butadiene rubber

(SBR), silico-butadiene rubber, especially applicable to sulfurizing butyl rubber.

2. It can be used to produce chloroprene rubber adhesive, with good compatibility with chloroprene adhesive. It is especially

applicable to the adhesive for shoes.

3.In coating industry, it can be used to produce end coating for external use, lacquer for floor, marine coating, antirust paint,

water based printing ink, and can be used as material of thin film anti-rust oil products.

4. It can be used both as sulfidizer, intensifier and tackifier when producing terylene adhesive tape, oil pipe anti-corrosive

adhesive and adhesive tape, etc, to improve the properties and extent the service period of products.

The effect will be even better if using 2402 resin together with terpene resin.

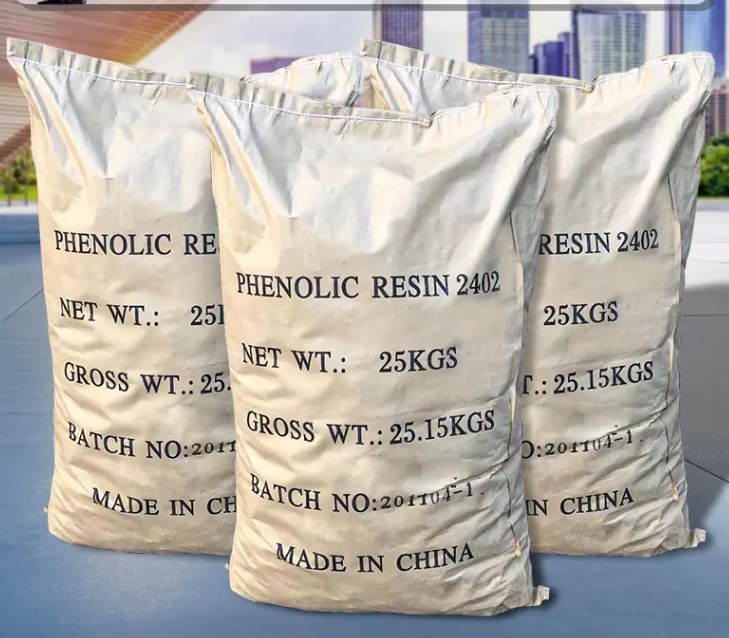

Packing & Delivery

Packing: in 25kg net plastic woven bag.

Hot Searches