Explore More Products

- Product Details

- {{item.text}}

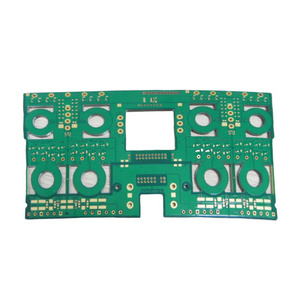

Quick Details

-

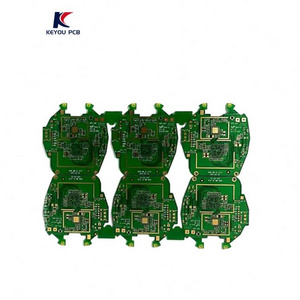

Type:

-

Rigid board

-

Place of Origin:

-

Hubei, China

-

Brand Name:

-

Yuwei

-

Copper Thickness:

-

1oz

-

Min. Hole Size:

-

0.25mm

-

Min. Line Width:

-

3mm

-

Min. Line Spacing:

-

3mm

-

Surface Finishing:

-

submerged gold

-

Board Size:

-

customized

-

Layer:

-

12

-

Outer layer line width/line spacing:

-

4/4mil

-

Solder resist character color:

-

Green

-

Applicable industry:

-

Computer

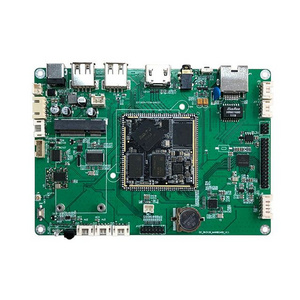

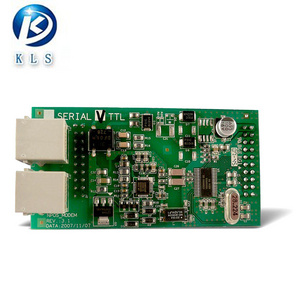

Quick Details

-

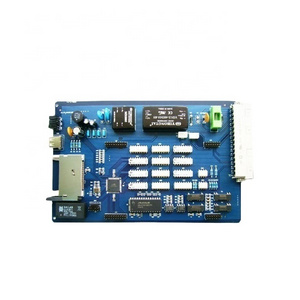

Base Material:

-

M6

-

Board Thickness:

-

5

-

Model Number:

-

YW-HDI-24- SB

-

Type:

-

Rigid board

-

Place of Origin:

-

Hubei, China

-

Brand Name:

-

Yuwei

-

Copper Thickness:

-

1oz

-

Min. Hole Size:

-

0.25mm

-

Min. Line Width:

-

3mm

-

Min. Line Spacing:

-

3mm

-

Surface Finishing:

-

submerged gold

-

Board Size:

-

customized

-

Layer:

-

12

-

Outer layer line width/line spacing:

-

4/4mil

-

Solder resist character color:

-

Green

-

Applicable industry:

-

Computer

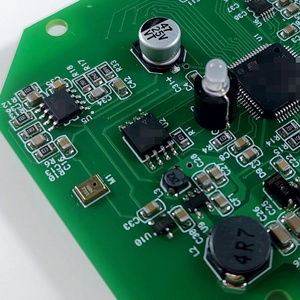

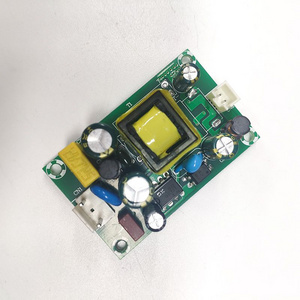

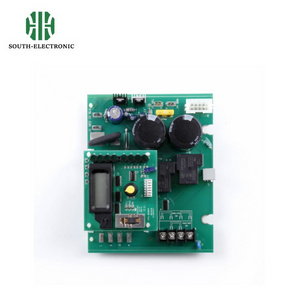

Base Material: FR-4 Board

Thickness: 1.6mm

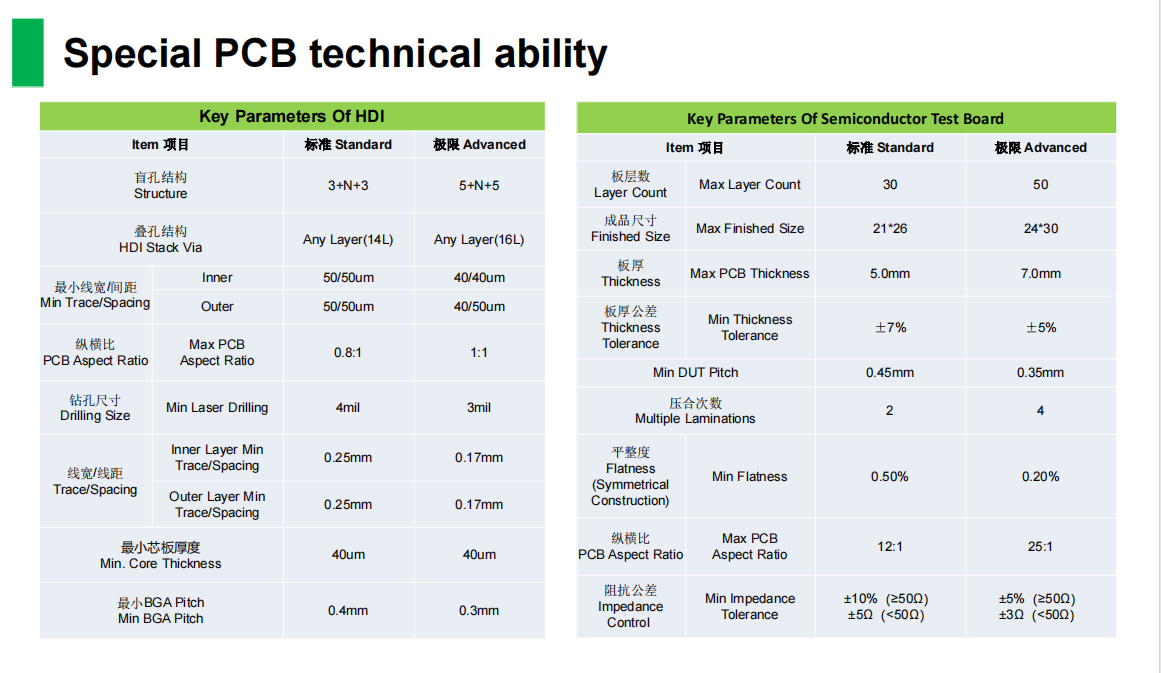

Min. Hole Size: 0.20mm

Min. Line Width: 3mi Min.

Line Spacing: 0.003

Surface Finishing: HASL

Solder mask: Customized

Type: Consumer Electronics PCBA

Copper Thickness: 3 oz

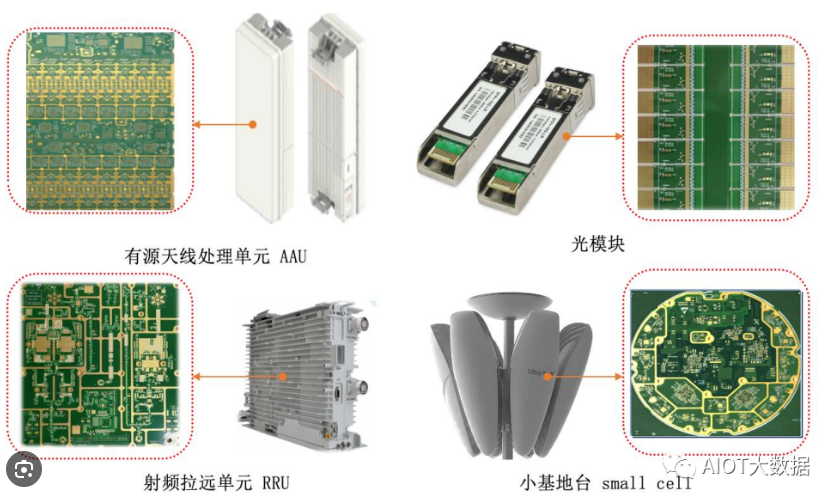

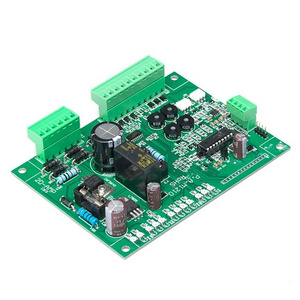

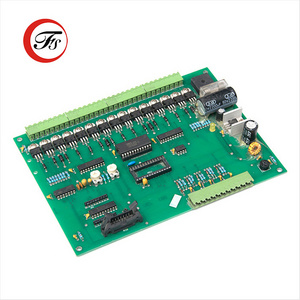

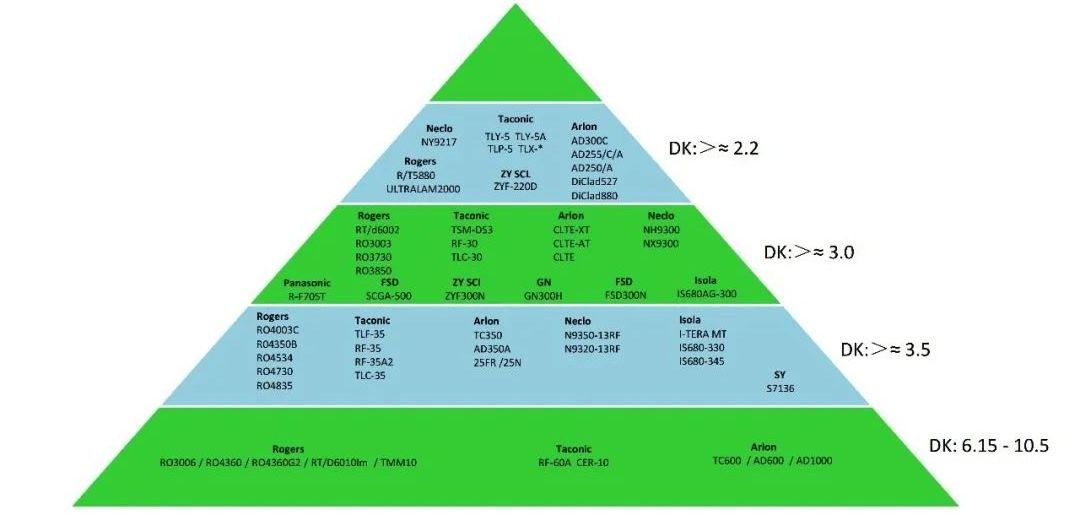

Selection of Backboard Plates

Backboard is usually made of FR4-TG170 or higher grade boards. Compared with general FR4-TG130, it has a higher glass transition temperature and better flame resistance. The dielectric constant is usually selected ε Plate with a Dk not greater than 4.4 to reduce signal crosstalk.

Quality control over PCB manufacturing

|

FAQ |

|

|

Question |

Answer |

|

What information does PCB need to provide ? |

Gberber files for PCB production, product process instructions, such as material requirements, surface treatment requirements, finished product thickness requirements, PCB stack structure diagram for high-end products, copper thickness requirements for each layer, sample quantity requirements, batch order requirements, product application areas, and other related information |

|

What information does PCBA need to provide? |

We need to provide a BOM report (requiring the brand, specifications, and model of the components), the X and Y coordinate tag numbers of the PCBA components, and processing requirements: Do you need us to purchase the components on your behalf? Or customer supplied components? Do you need software burning? What is the required quantity? What is the monthly demand and other detailed information. |

|

Is my file secure? |

Your files are very secure, and we protect intellectual property for our customers throughout the entire process. All files provided by the customer will never be shared with any third party. |

|

What is the minimum order quantity? |

There is no minimum order quantity in POE. We can flexibly handle small and large orders. |

|

Do you have any other services? |

We mainly focus on the procurement services of PCB+FPC production+SMT+assembly PCBA+components; In addition, we can also provide programming, testing, software burning, cable laying, and shell assembly services; And product design, product development, software development

|

|

What is your inspection method? How do you control quality? |

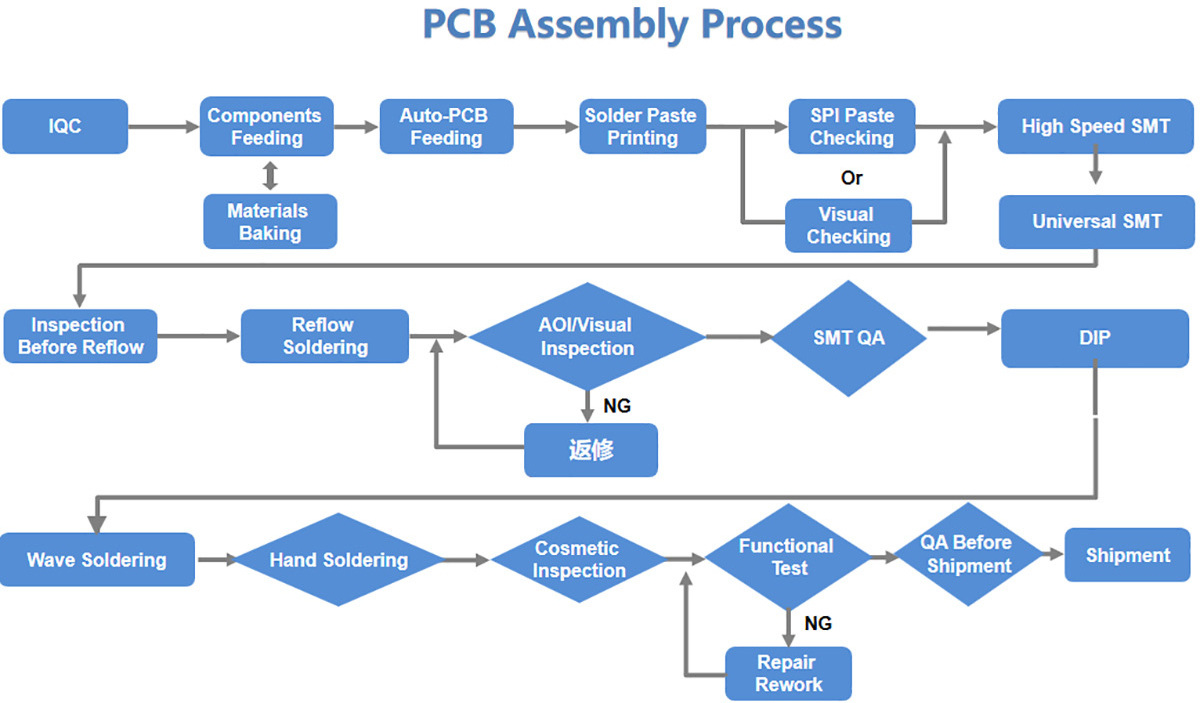

In order to ensure the quality of PCB and FPC products, flying needle testing is usually used for samples and small batches; The inner circuit undergoes AOI optical inspection, online AOI inspection, and the finished product undergoes 100% inspection through the E-SET testing rack. The appearance undergoes 100% inspection through fully automatic finished product inspection equipment and FQC100% inspection. PCBA automatic optical inspection (AOI), BGA parts X-ray 100% inspection, first article inspection (FAI), PCBA products that require software burning, and 100% full testing through the finished product testing rack according to product functional requirements. |