- Product Details

- {{item.text}}

Quick Details

-

Warranty:

-

1year

-

Place of Origin:

-

Tianjin, China

-

Brand Name:

-

Bridge

-

Model Number:

-

THZ208

-

Operating Current:

-

DC AC

-

Application:

-

gray iron castings

-

Product Name:

-

Welding Rod

-

Color:

-

Grey

-

Advantage:

-

Small Splash

-

Standard:

-

AWS

-

Packing:

-

10kg/carton

-

MOQ:

-

500kg

-

Certification:

-

ISO9001

-

Brand:

-

Bridge Brand

Quick Details

-

Material:

-

Cast Iron

-

Welding Current:

-

90-200

-

Operating Temperature:

-

Standard Temperature

-

Warranty:

-

1year

-

Place of Origin:

-

Tianjin, China

-

Brand Name:

-

Bridge

-

Model Number:

-

THZ208

-

Operating Current:

-

DC AC

-

Application:

-

gray iron castings

-

Product Name:

-

Welding Rod

-

Color:

-

Grey

-

Advantage:

-

Small Splash

-

Standard:

-

AWS

-

Packing:

-

10kg/carton

-

MOQ:

-

500kg

-

Certification:

-

ISO9001

-

Brand:

-

Bridge Brand

|

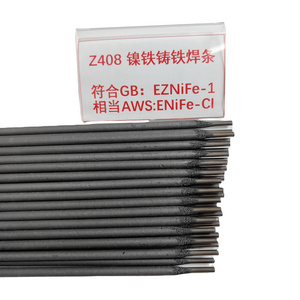

THZ208 |

Steel C ored G ray C ast I ron E lectrode

GB/T 10044 EZC

DFCC1 JIS

Application: welding up the defects of gray iron castings.

Features: THZ208 is the cast iron electrode with a low - carbon steel core and strong graphite type coating . It can be used in AC and DC dual purpose and has a low price. The welding seam can be changed into gray cast iron when it is cold slowly . But it has a poor anti cracking performance.

Precautions:

1 B efore welding , the electrode s need to be bake d for 1 hour with the temperature of 150±10℃ before using.

2 The defects in s mall thin - wall castings with little stiffness may not be preheated weld repairs, while the general welding should be preheated to 400±10℃ , kept welding heat preservation, and slow cooling, then the welding repair may be able to carry out cutting processing.

3 This electrode b should not use d to important casting structures that withstand stresses and shocks.

Chemical Composition of the deposited metal(the mass fraction): %

|

Elements |

C |

Si |

Mn |

S |

P |

Fe |

|

S tandard value |

2.0-4.0 |

2.5-6.5 |

≤0.75 |

≤0.10 |

≤0.15 |

margin |

Welding reference current (AC, DC + )

|

Electrode diameter( mm ) |

3.2 |

4.0 |

5.0 |

|

Welding current ( A ) |

90-120 |

150-180 |

190-220 |

--- PRODUCT DISPLAY ---

--- PRODUCT APPLICATION ---

Some of our products have been applied to overseas key projects.

Electrode, SAW wire and flux of 600MPa Grade & 800MPa Grade applied to hydro steel at Laos pumped storage power station E6010 cellulose electrode Applied to the Ghana TEMA pipeline project in Africa successfully. It breaks the monopoly of Bohler cellulose electrode and won the bidding of oil pipeline Ghana tank project.

--- RELATED PRODUCTS ---

|

|

--- COMPANY PROFILE ---

--- FACTORY DISPLAY --- --- EXHIBITION PHOTOS --- --- PRODUCTION DETAILS --- --- PACKING AND DELIVERY --- --- F A Q ---

Q: what is delivery time / lead time ?

A: 30 days

Q: what is your minimum order ?

A: 5000kgs

Q: what is your payment term ?

A: 1- 30% down payment for order confirmation, 70% before shipment. 2- 100% at sight LC

Q: can we visit your factory ?

A: yes you can at your free time.