- Product Details

- {{item.text}}

Quick Details

-

Application:

-

hrm/lm/zgm vertical roller wearing parts

-

Vertical Mill Model:

-

HRM/LM/ZGM

-

Weight:

-

roll tire 653kg / liner 105kg

-

Color:

-

Request

-

Usage:

-

metallurgy, electric power, cement, chemical, non-metallic minerals

-

Main material:

-

high chromium cast iron

-

MOQ:

-

1ton

-

Price:

-

negotiable

Quick Details

-

Place of Origin:

-

Shanghai, China

-

Product name:

-

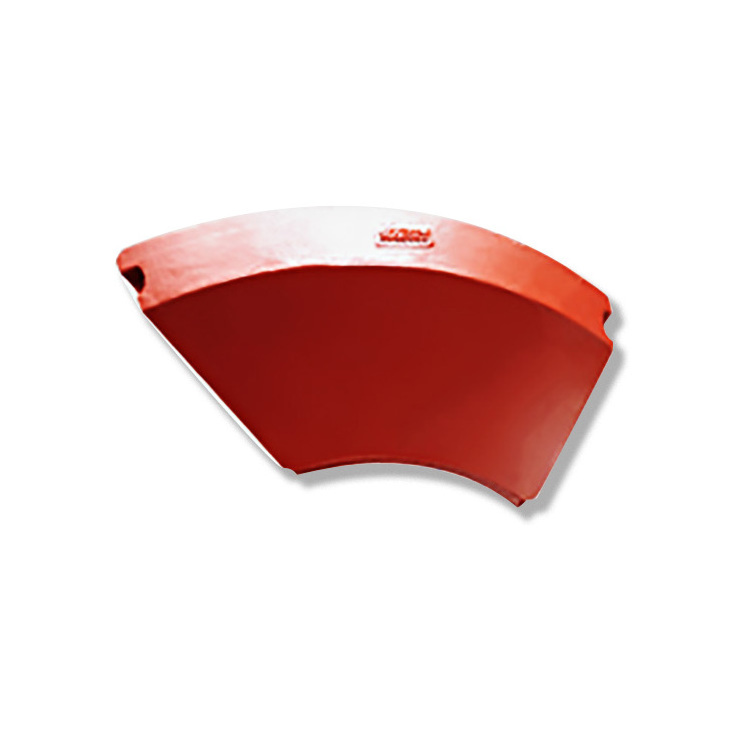

roller mill wear parts grinding roller tire table liner segments

-

Keywords:

-

table liner segments

-

Application:

-

hrm/lm/zgm vertical roller wearing parts

-

Vertical Mill Model:

-

HRM/LM/ZGM

-

Weight:

-

roll tire 653kg / liner 105kg

-

Color:

-

Request

-

Usage:

-

metallurgy, electric power, cement, chemical, non-metallic minerals

-

Main material:

-

high chromium cast iron

-

MOQ:

-

1ton

-

Price:

-

negotiable

Production Description

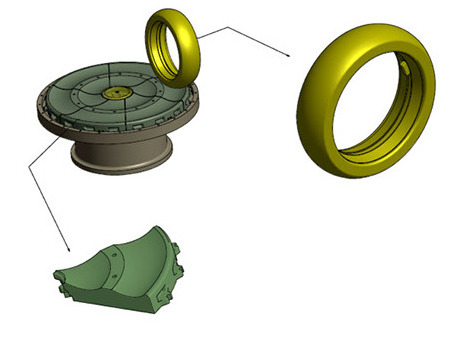

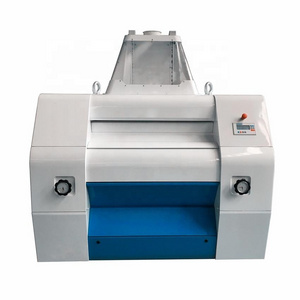

We manufacture different wear and impact resistant parts for your vertical mill , for example: roller tire, segmented rollers, table liners and nozzle rings. Beside suitable material selection we offer hard weld deposit and other special applications to increase the surface hardness.

High-chromium wear-resistant roll sleeves are widely used in large-scale materials such as metallurgy, electric power, cement, chemical, ceramics, non-metallic minerals, power plant desulfurization, water slag, slag, slag, coal, cement clinker, glass, quartz, limestone and other industries. Grinding and ultra-fine grinding.

Rollers and Table Segments: Both are cast in High Chrome Alloys in the range of 16% to 27 % with a 55-62 HRC hardness. The use of High Chrome increases the wear life versus low and medium chrome alloys.

Grinding roller is core part of vertical mill. We can provide customized service according to customers'different processing requirements. Besides, it provides finished product manufacturing service for grinding roller including casting, finished machining, surfacing welding, etc. We gained good reputation from customers.

Application Area

Vertical Mill/ Cement Vertical Mill/ Coal Vertical Mill/ Raw Vertical Mill/ Slag Vertical Mill / Clinker vertical mill/ GGBS vertical mill

Key Features

- Longer using time & Lower repairing cost

- Optimal Production Efficient

- Cost Saving

- Customized Products

- Environmentally Friendly

Advantages

1. High hardness, grinding a variety of materials

High hardness, Rockwell hardness (HRC) up to 65 degrees, can grind pyrophyllite, calcite, limestone, quartz, gypsum, slag and other materials.

2. Crack-proof, wear-resistant, overload

It adopts high-chromium cast iron grinding material and exquisite metal casting technology. It has good size and crack resistance, good wear resistance and strong load bearing capacity. It has no cracking for 20 years.

3. Reserve price sales, cost-effective

We promised a price of 3,000 yuan per ton than the original or original offer!

4. Layers check and Taiwan time high output

After the factory has passed 17 professional inspections, the quality inspection system is strictly implemented, and the output is high.

Specification

We Supply...

We supply replacement wear parts such as tires, grinding ring segments, armor rings and spindle shields are cast from our high chromium alloy irons and fully heat-treated for optimum mechanical properties. Tires and grinding ring segments are also accurately machined to tight tolerances for a precise fit.

Parts requiring drilled or tapped holes such as roller bosses, clamping rings and dam ring segments are made of carbon steel or high strength steel. They are heat-treated to provide the best combination of hardness and toughness for long, trouble-free service.

Our product engineers are responsive to customer requests for product improvement. As a vertically integrated plant, we can easily deal with the changes in design, metallurgy, heat treatment and machining.

We offer customized services. You can send us your drawings of your vertical mill wear parts in the case that we have not had developed your mill parts in the past. WhatsApp Us: 008613917147829