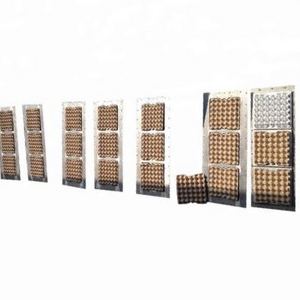

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

JK-0403

-

Item:

-

Egg tray mold making

-

Cavity:

-

single

-

Runner:

-

cold/ hot runner - point way, side way, follow way, direct gate way

-

Design software:

-

UG,PROE,CAD

-

mould material:

-

45#, 50#, P20, H13, 718, 2738, NAK80, S136, SKD61 etc.

-

mould life:

-

1million shots

-

Surface Treatment:

-

polishing

-

MOQ:

-

1 set

-

Mould:

-

Plastic Injection Mould

-

Mould base:

-

HASCO standard, European standard, World standard

Quick Details

-

Shaping Mode:

-

Plastic Injection Mould

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

KJ MOULD

-

Model Number:

-

JK-0403

-

Item:

-

Egg tray mold making

-

Cavity:

-

single

-

Runner:

-

cold/ hot runner - point way, side way, follow way, direct gate way

-

Design software:

-

UG,PROE,CAD

-

mould material:

-

45#, 50#, P20, H13, 718, 2738, NAK80, S136, SKD61 etc.

-

mould life:

-

1million shots

-

Surface Treatment:

-

polishing

-

MOQ:

-

1 set

-

Mould:

-

Plastic Injection Mould

-

Mould base:

-

HASCO standard, European standard, World standard

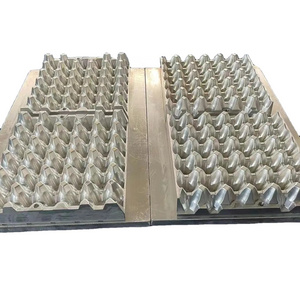

Product Description

Specification

|

Product Material

|

PP/PE/PET/PA/PA66/PS/PC

|

|

Cavity

|

Mulit Cavity

|

|

Mould Material

|

P20/718/S136/H13/2311/2738/2344 Steel

|

|

Mould Life

|

1-5 Million

|

|

Mould base

|

LKM,HASCO

|

|

Runner Type

|

Hot/Cold Runner

|

|

Design software

|

UG,PROE,CADetc.

|

Packing & Delivery

1.Check mould component

2.Cleaning mould cavity/core and spread slushing oil on the mould

3.Cleaning mould surface and spread slushing oil on the mould surface

4.Put into the wooden case

2.Cleaning mould cavity/core and spread slushing oil on the mould

3.Cleaning mould surface and spread slushing oil on the mould surface

4.Put into the wooden case

Hot Searches