- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

1500 KG

-

Power (kW):

-

18

-

Name:

-

Wood Pallet Block Leg Extruding Machine

-

Application:

-

Wood pallet package logistic

-

Usage:

-

Wood pallet feet

-

Raw material:

-

Wood shaving wood sawdust and glue water

-

Key words:

-

wood pallet block making machine

-

Package:

-

export wooden package

-

Product name:

-

Wood pallet leg block

-

Working Principle:

-

hot press

-

Type:

-

waste wood recycling machine

-

Advantage:

-

Automatic wood pallet block machine

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Delarry

-

Machine Type:

-

Wood sawdust compress machine

-

Weight (KG):

-

1500 KG

-

Power (kW):

-

18

-

Name:

-

Wood Pallet Block Leg Extruding Machine

-

Application:

-

Wood pallet package logistic

-

Usage:

-

Wood pallet feet

-

Raw material:

-

Wood shaving wood sawdust and glue water

-

Key words:

-

wood pallet block making machine

-

Package:

-

export wooden package

-

Product name:

-

Wood pallet leg block

-

Working Principle:

-

hot press

-

Type:

-

waste wood recycling machine

-

Advantage:

-

Automatic wood pallet block machine

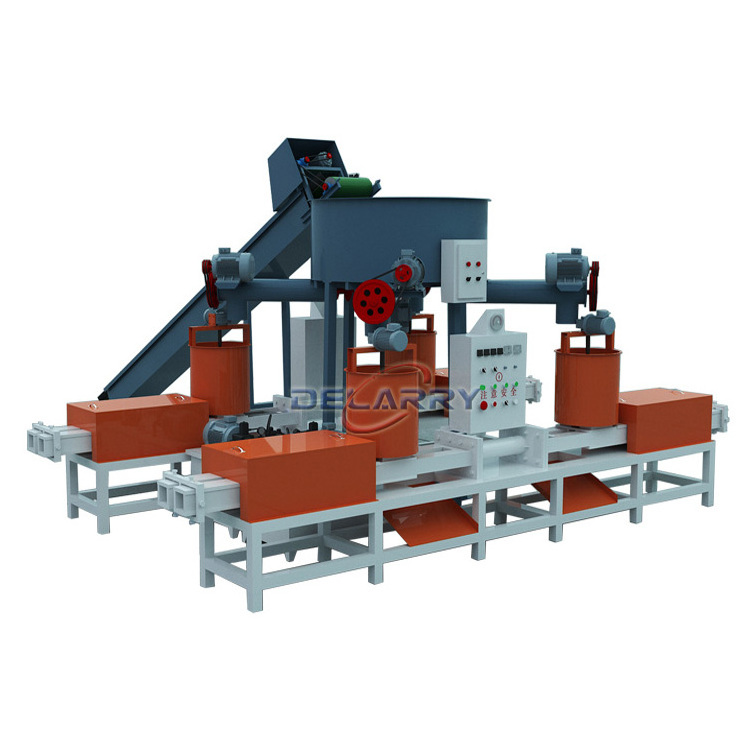

Industrial Wood Pallet Feet Making Machine Wood Shaving Block Compress Machine Round Block Extruder

1. Brief description of wood pallet block making machine:

Wood sawdust block making machine(wood pallet block machine) is used to make wood blocks/feet/log for pallets, which can be used in export standard pack.

1) Raw material is wood sawdust and shavings whose moisture should be less than 15%, uniform mixed with glue, then pressed by wood sawdust block making machine as wood pallet block with good appearance, uniform size and no residues; also has water proof function (48hours without cracking in water, exposure without crack) .

2) Wood pallet block exempted from inspection, fumigation-free, formaldehyde release quantity (E2), all meet the national standards, adhesive strength up to1.07MPA, the vertical screw force is 1590 N, Level force is 1660 N, which is mainly used for instead of the raw wood block.

3) The wood block making machine can produce different size blocks, such as 75*75, 80*80,80*100, 80*120, 90*90,100*100, 100*115, 100*140,90*120,140*140, also the block could be with hole or without hole as customer's requirement. We can customize the wood block making machine to meet your request.

4) We also could provide automatic wood pallet block production line, which includes wood shaving machine/ crusher, wood sawdust dryer, glue mixer, wood block making machine, automatic block cutting machine etc.

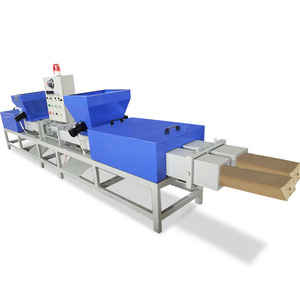

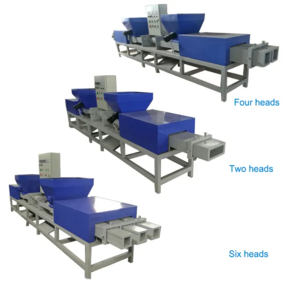

2. Main technicial parameters of wood pallet block machine:

There are 3 different productivity pressing machines, it's 6-8m3/24h(6 head), 5-6CBM/24h(3 head ), 2-3m3/24h(two head).

The block machine could make different size wood block as per your request, such as 75*75, 80*100, 80*120, 90*90, 95*75, 80*80, 90*140,100*100,100*115,100*140,140*140 ,145*145 etc.

|

Model |

Double Head |

Four Head |

Six Head |

|

Size |

4900*660*1800 |

4900*800*1800 |

4900*940*1800 |

|

Capacity |

2-3m3/24h |

4-6m3/24h |

6-8m3/24h |

|

Glue water amount |

100-120kg/m3 |

100-120kg/m3 |

100-120kg/m3 |

|

Density |

550-700kg/m3 |

550-700kg/m3 |

550-700kg/m3 |

|

Weight |

1000kg |

1500kg |

2200Kg |

|

Power |

12kw |

16-18kw |

24kw |

3. More informations of the wood pallet block processing machine for your reference:

4. The automatic line of wood pallet block compress line:

The production line can be realized full automatic operation,minimizes manual labor. The whole production line just needs 2-4 people to complete process. At the same time, the dust-free work has been realized, which makes the working environment much better. Another, the three-dimensional structure production line can be designed according to the specific size of the customer workshop,which is two-storey design, the problem of insufficient workshop area has been solved.

5. Package and Delivery of wood sawdust block making machine:

6. Customers visiting of our factory:

7. Contact details of wood pallet block processing machine:

If you need more details of the pallet leg/block/feet making machine, please contact with us freely, we are always at your service.