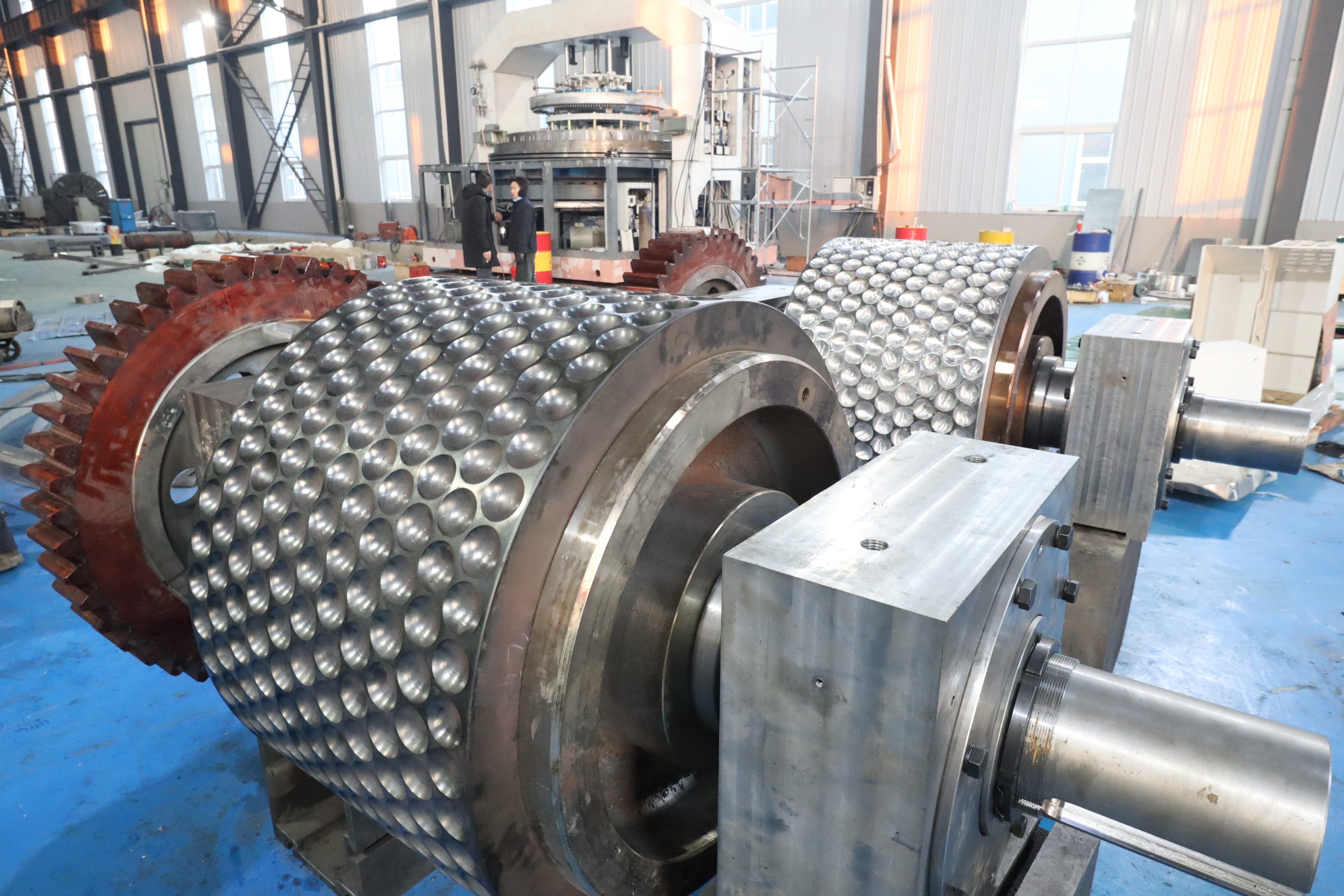

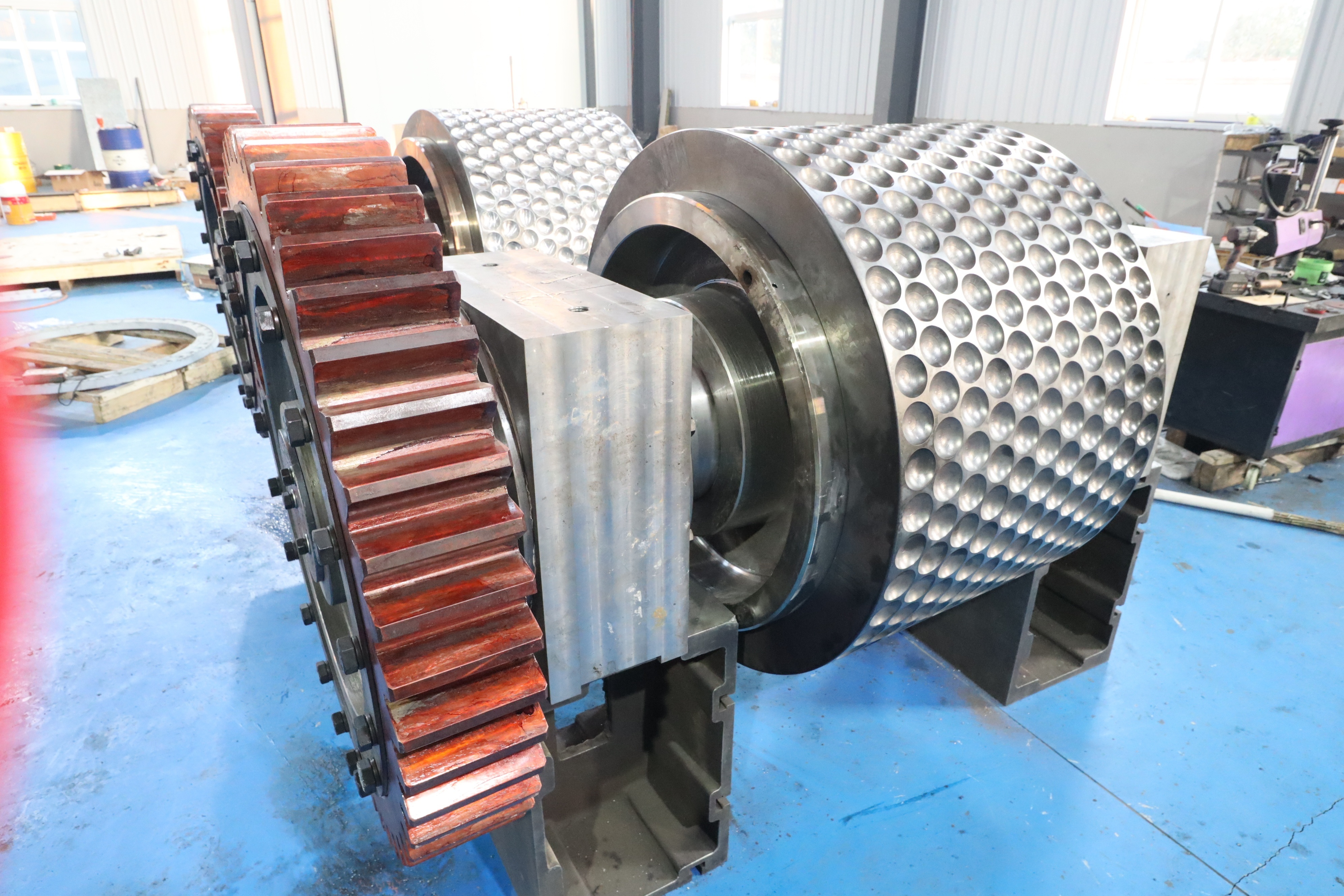

Briquetting machine dimpled roller shell

Briquetting machine dimpled roller shell

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

custom

-

Dimension(L*W*H):

-

custom

-

Weight:

-

300 kg

-

Marketing Type:

-

New Product 2022

-

Core Components:

-

Roller Shell

-

Product name:

-

pellet mill roller shell

-

Size:

-

According to drawings

-

Process:

-

Lathing, milling, drilling

-

Defect control:

-

UT,MT

-

Application:

-

Mining machinery

-

Model Number:

-

Customized

-

Material:

-

GCr15SiMn, alloy steel

-

Machine type:

-

Vertical Animal Feed Mixer Equipment

-

Advantage:

-

High Performance

-

Packing:

-

Plywood Case

Quick Details

-

Max. Capacity:

-

20 ton/h

-

Place of Origin:

-

Luoyang,Henan,China

-

Brand Name:

-

yogie

-

Voltage:

-

custom

-

Dimension(L*W*H):

-

custom

-

Weight:

-

300 kg

-

Marketing Type:

-

New Product 2022

-

Core Components:

-

Roller Shell

-

Product name:

-

pellet mill roller shell

-

Size:

-

According to drawings

-

Process:

-

Lathing, milling, drilling

-

Defect control:

-

UT,MT

-

Application:

-

Mining machinery

-

Model Number:

-

Customized

-

Material:

-

GCr15SiMn, alloy steel

-

Machine type:

-

Vertical Animal Feed Mixer Equipment

-

Advantage:

-

High Performance

-

Packing:

-

Plywood Case

Products Description

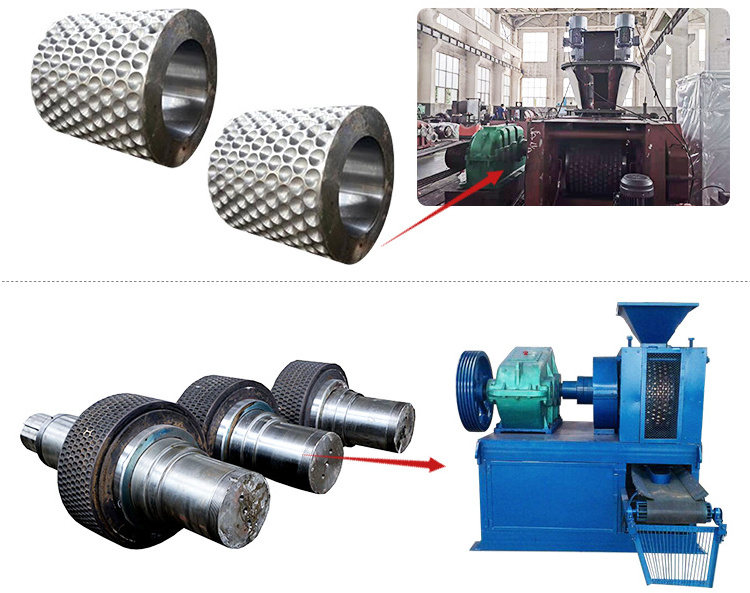

Factory price high quality OEM Wear Resistance Coal Pellet Mill Roller Shell roller press spare parts

The roller shell is an important component of the briquette machine. The roller shell determines the shape of briquette machine. According to the different ways of assembly into one and separate.According to the needs of different users, the roller shell of the briquette machine is mainly divided into different shapes, such as oval shape, trapezoid, cuboid and so on

.

|

Product name

|

Roller shell for ball press machine

|

|

Material

|

GCr15SiMn

|

|

Structure

|

Casting

|

|

Process

|

Lathing, Milling, Grinding

|

|

Heat treatment

|

Surface quenching HRC 58-62

|

|

Type

|

According to drawings

|

|

Length

|

635mm

|

|

Diameter

|

650mm

|

|

Tolerance

|

±0.1

|

|

Weight

|

525kg

|

|

Package

|

Seaworthy packing

|

|

Delivery time

|

30 - 90 days

|

|

Certificate

|

ISO9001-2008

|

Our briquette machine ZY 1000-150 have been export to Mongolia

Advantage of our company

1.Supply the custom service, we can custom various of roller shell according to customer’s drawing and requirements

2.Advance equipment, all our equipment are CNC equipment, which can ensure high precision

and stable performance.

1.

Accept material experiment

2.Long service life 3.High ball forming rate

Our roller shell can be used on the diffierent type of the briquette machine.

About us

Luoyang Yujie Industry Trade Co,Ltd is established in 2004,is mainly engaged in the designing and manufacturing of large machinery components and non-standard machinery parts according to customer's request, including shafts, gears, sprockets, mining machinery parts, welding, bearings, castings and forgings etc. The products are mainly used in the fields of mining, petroleum, cement,steel mill, power plant, sugar factory etc.

roller press spare parts

roller press spare parts

roller press spare parts roller press spare parts

roller press spare parts

Quality Control

All tests conform to ISO 9001 quality management system certification standards,supporting the third party inspection commissioned by customer.

roller press spare parts roller press spare parts roller press spare parts roller press spare parts roller press spare parts

Our Equipment

All our equipment adopts the advanced CNC machine tools,especially large CNC gantry milling and boring machine, CNC floor-type boring machine.

CNC gantry milling and boring machine,CNC machining center equipped with the fourth axis, CNC floor-type boring machine is equipped with the fourth axis and rotary worktable, it can realize five axis machining. The work piece is not limited by the size.It is suitable for machining large module and large size gear, boxes,and large non -standard parts.

CNC gantry milling and boring machine,CNC machining center equipped with the fourth axis, CNC floor-type boring machine is equipped with the fourth axis and rotary worktable, it can realize five axis machining. The work piece is not limited by the size.It is suitable for machining large module and large size gear, boxes,and large non -standard parts.

Our company has a series of advanced equipments:XV6032,HXV4032,HXV3017,HXV2017CNC gantry boring and milling machine,TX130CNC floor-type boring machine,DVT-500,HK1600CNC vertical lath,CK6136CNC horizontal lath etc,to ensure high precision and stable performance of products.

Briquetting machine dimpled roller shell

Briquetting machine dimpled roller shell

Briquetting machine dimpled roller shell

Customer Comments

Customer Visit

Certifications

Contact Us

Hot Searches