- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

99%

-

Voltage:

-

280v/50Hz

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

kingpack

-

Dimension(L*W*H):

-

1000*800*1600mm

-

Weight:

-

300 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Online support, Video technical support

-

Product name:

-

Semi-automatic Cartridge Filling machine for silicon sealant

-

Function:

-

round bottle labeling machine

-

Power Supply:

-

220v/50Hz

-

Production capacity:

-

20-120 Bottle/min

-

Product size applicable:

-

Round Bottle diameter 20mm~100mm

-

Applicable label size:

-

15≤width≤110mm (110mm~180mm customized), length≥20mm

-

Certification:

-

ISO CE

Quick Details

-

Machinery Capacity:

-

20000BPH

-

Packaging Material:

-

Wood

-

Filling Material:

-

Other

-

Filling Accuracy:

-

99%

-

Voltage:

-

280v/50Hz

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

kingpack

-

Dimension(L*W*H):

-

1000*800*1600mm

-

Weight:

-

300 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Online support, Video technical support

-

Product name:

-

Semi-automatic Cartridge Filling machine for silicon sealant

-

Function:

-

round bottle labeling machine

-

Power Supply:

-

220v/50Hz

-

Production capacity:

-

20-120 Bottle/min

-

Product size applicable:

-

Round Bottle diameter 20mm~100mm

-

Applicable label size:

-

15≤width≤110mm (110mm~180mm customized), length≥20mm

-

Certification:

-

ISO CE

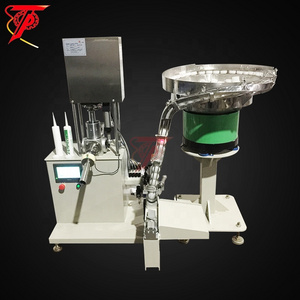

Semi-automatic Cartridge Filling machine for silicon sealant

Semi-automatic Cartridge Filling machine for silicon sealant

Click here to send a inquiry for details!

Semi-automatic Cartridge Filling machine for silicon sealant

The cartridge filling machine is one of our new design. It is mainly used for glass glues and adhesives, especially for silicon sealant, glass cement, and nail-free glues. This machine is composed by hydraulic extrude system, glue dosing system and automatic capping system . Only one operator can control the whole machine.

Main technical parameters :

|

Power supply |

220V/50Hz |

|

Filling speed |

20~30pcs/min |

| Suitable diameter |

20mm~ 100mm |

|

Filling volume |

310ml ( φ 46 cartridge) |

|

F illing accur acy |

≤ ±1 % |

|

D imension |

1000*800*1600mm |

Working pressure:0.6Mpa

Hydraulic extruder system: suitable for 200L drum

Features

1. Quantitative dosing system: The system is controlled by PLC. High-precision servo and the high-precision screw control the dosage with high speed and adjustable parameter.

2. Extruding system: the material is extruded by hydraulic pressure system with pressure of at least 80T. It is suitable for standard 200L drum.

3. The hydraulic pressure is separate from the working pressure.The output working pressure is constant to ensure a steady filling performance and the hydraulic motor controls the pressure of the system .

4. Filling system: the parts composed are world famous brands, which keep a steady operation and long lifespan of the whole machine

5. Working flow: manual filling + automatic cap feeding + automatic cap closing. The operation is simple.

6. The parts contacting with product is made of quality SUS 304 , anti-corrosive, and easy to clean.

7. Finished products are collected to the tray automatically

Picture reference : (The design of the machine could according to the request of the clients,it's not changeless, If you have purchase plan about the machine , please tell us your detailed request ,we will make a suitable solution accordingly) Best sale injection vial bottle filling and capping machine 300ml bottling equipment

Click here to send a inquiry for details!

Application range Professional equipment eye drop filling and capping machine

It is mainly used for glass glues and adhesives, especially for silicon sealant, glass cement, and nail-free glues.

Click here to send a inquiry for details!

Layout : ( we could design the size according to your factory space) Quality assurance eye drop bottle filling capping machine