- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

Customers request

-

Dimension(L*W*H):

-

15*10*4m

-

Year:

-

New

-

Weight (KG):

-

20000 kg

-

Power (kW):

-

200

-

Application:

-

Tire Rubbers Recycling Industry

-

Name:

-

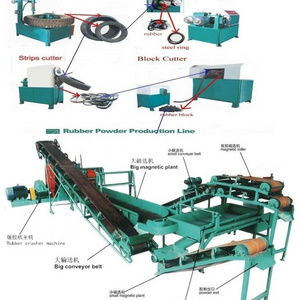

Waste Rubber Tyre Recycle Machine

-

After-sales Service Provided:

-

Service Machinery Overseas

-

Raw material:

-

Waste Tyre Tire Rubber

-

Function:

-

Tire Powder Recycling Machine

-

Keyword:

-

High Efficiency

-

Usage:

-

Recycling Waste

-

Product name:

-

Waste Rubber Recycling Line

-

Type:

-

Rubber Cutting Machine

-

End product:

-

Rubber Block

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

FANTE

-

Model Number:

-

Auto-Semi Tire Cutting System

-

Voltage:

-

Customers request

-

Dimension(L*W*H):

-

15*10*4m

-

Year:

-

New

-

Weight (KG):

-

20000 kg

-

Power (kW):

-

200

-

Application:

-

Tire Rubbers Recycling Industry

-

Name:

-

Waste Rubber Tyre Recycle Machine

-

After-sales Service Provided:

-

Service Machinery Overseas

-

Raw material:

-

Waste Tyre Tire Rubber

-

Function:

-

Tire Powder Recycling Machine

-

Keyword:

-

High Efficiency

-

Usage:

-

Recycling Waste

-

Product name:

-

Waste Rubber Recycling Line

-

Type:

-

Rubber Cutting Machine

-

End product:

-

Rubber Block

▶︎

Waste tire recycling rubber powder machine is suitable for different kind of acrap tires,and we can provide you the best solution on your different tires.

|

Model

|

Single Hook Tire Debeader

|

|

Motor power

|

15kw

|

|

Tire Size

|

≤1200 mm

|

|

System pressure

|

<20 Mpa

|

|

Max run distance of extracting cylinder

|

1250mm

|

|

Max run distance of pressing cylinder

|

350mm

|

|

Capacity

|

30-45 pcs

|

|

Hook lifespan

|

6000(surfacing and grinding repeatedly)

|

|

Size

|

4300*1030*1550

|

|

Weight

|

2700 kg

|

The hydraulic station,hydraulic clinder,control cabinet and so on etc fixed on the framework of equipment,so the whole equipment is simple structure,nice appearance,easliy transported and installed.Adopted vance piump supply oil lower the noise during the equipment running and pull-out the steel wire as normal speed during the press cylinder working,which improve the working effciency and liftspan of hydraulic parts.Used working way of the unladen hook reach out,load bead cutted in slow speed and hydraulic bead wire pulled out,which improve the production effciency.Ruduce labor intensity via using the lift device.

|

Equiment Name

|

Hydraulic Tire Cutter

|

|

Motor Power

|

5.5kw

|

|

Processing Range

|

750-1400mm

|

|

Capacity

|

15-20 pcs

|

|

Weight

|

1500 kg

|

|

Size

|

1720*950*1880

|

|

Model

|

FTHS-T-1200

|

FTHS-T-800

|

|

|

Motor Power

|

(22-45)kw*2

|

(15-37)kw*2

|

|

|

Main Shaft Rotation Speed

|

5-14 Rpm

|

|

|

|

Input Size

|

≤1200 mm

|

≤800mm

|

|

|

Final Product

|

≤50*50mm

|

|

|

|

Size

|

6310*3670*3450

|

4400*2200*3100

|

|

|

Weight

|

16500kg

|

5700kg

|

|

FTHS-T tire shredder is controlled by PLC unit enabling automatic reverse for overload protection and minimizing blades damages.

Our knife design operates at extremely close tolerances which produces the clean cut with very little exposed wire, and with over 13 processing steps ensure the best performance and precision tolerance. The knives can be resharpened and reused which significantly increases lifespan and decreases costs.

|

Model

|

FT-XKP-400

|

FT-XKP-450

|

FT-XKP-560

|

FT-XKP-610

|

|

Front Roller Diameter

|

400

|

450

|

560

|

560

|

|

Rear Roller Didmeter

|

400

|

450

|

510

|

610

|

|

Working Length Of Rooller

|

600

|

650

|

800

|

1000

|

|

Front Rooller Surface Speed

|

17.32

|

23.2

|

25.56

|

24.72

|

|

Friction ratio

|

1:1.38

|

1:1.38

|

1:1.3

|

1:1.9

|

|

Max.nip

|

8

|

8

|

15

|

16

|

|

Motor power

|

45

|

55

|

90/132

|

132

|

|

Dimension

|

3950*800*1780

|

4770*1846*1835

|

5064*2084*1978

|

5899*2270*2060

|

|

Weight

|

7500

|

9200

|

17500

|

19500

|

1.There are two kinds of materials can be chooscd fbr crusher rollers—cast iron and cast steel.the roller made of chilled cast iron with vanadium and titanium alloys is hard and anti-wear.The working surface of cast steel roller choose welding cemented carbide, its rear roller is processed in groove type, its driving part is equipped with hardened reducer, all of those characters make crusher work in good peribnnance and lower noise.

2.It is equipped with an overload protection device to prevent the major components from being damaged due to overloading.

3.It is equipped with an emergency device.when an emergency accidents happens,press the saiety button,the machine will stop immediately.

4.It is equipped with auto grease device fbr bearing,that operated convenient and easily.

◼︎

Simple construction,easy installation and maintenance

◼︎

Separate metal materials completely

◼︎

Long lifespan,less rreparation and maintenance

|

Model

|

FTMS-1200

|

FTMS-800

|

FTMS-600

|

||

|

Excitation broadband

|

450mm

|

|

|

||

|

Excitation hang height

|

≤180mm

|

|

|

||

|

Material thickness

|

≤20mm

|

|

|

||

|

Conveyor speed

|

≤4.5m/s

|

|

|

||

|

Power

|

1 kw

|

|

|

||

|

Size

|

1350*500*550

|

950*500*550

|

750*500*550

|

||

|

Weight

|

550

|

450

|

380

|

||

◼︎

High selecting precison,the classification can be adjustable between 15-150mesh

◼︎

High efficient classification and wide application

◼︎ Adopted automatic air flow circulation with funtion of classifying and gathering

◼︎ Long lifetime,simple installation and maitenance

|

Equiment Name

|

Fiber/Nylon Separator

|

|

Motor power

|

11kw

|

|

Rotor speed

|

2650 r/min

|

|

Classifier size

|

⌀800 mm

|

|

Classify range

|

for classifying fiber from 5-40 mesh

|

|

Capacity

|

600-650 kg/h

|

|

Selection ratio

|

≥99.5%

|

|

Size

|

1600*1200*2350

|

|

Weight

|

1200kg

|

Hot Searches