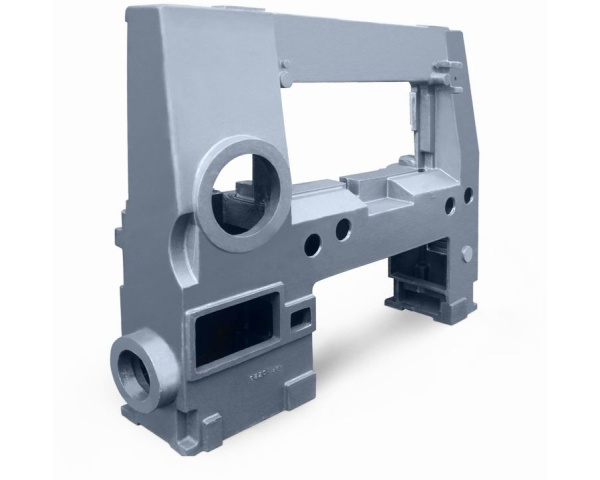

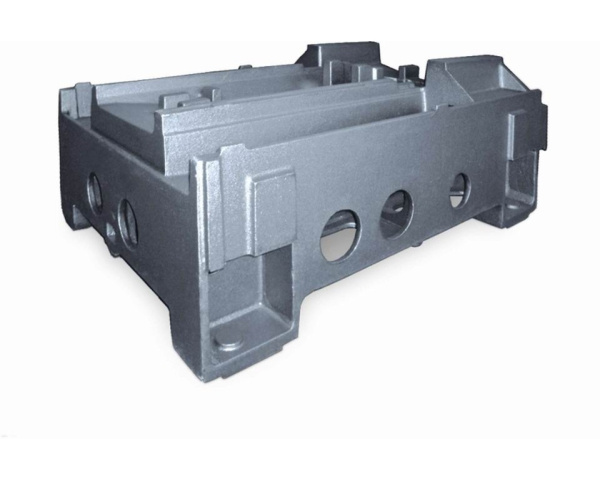

- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

Casting parts

-

Material:

-

Grey Iron/Ductile iron

-

Surface treatment:

-

Shot Blasting

-

Certification:

-

ISO9001/TS16949/RoHS

-

Process:

-

Casting +Machining(if Need)+surface Treatment

-

Tolerance:

-

Customer's Drawing Request

-

Shape:

-

Customized Shape

-

Machining Process:

-

Machining Center

-

Keyword:

-

Casting Processing Products

-

Application:

-

Industry Machinery

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Shengrong

-

Model Number:

-

SR

-

Product name:

-

Casting parts

-

Material:

-

Grey Iron/Ductile iron

-

Surface treatment:

-

Shot Blasting

-

Certification:

-

ISO9001/TS16949/RoHS

-

Process:

-

Casting +Machining(if Need)+surface Treatment

-

Tolerance:

-

Customer's Drawing Request

-

Shape:

-

Customized Shape

-

Machining Process:

-

Machining Center

-

Keyword:

-

Casting Processing Products

-

Application:

-

Industry Machinery

Products Description

1. Material: Gray Iron or Ductile Iron, Steel

Gray iron HT200-350 (GG20-35, FC200-350);Ductile Iron QT400-QT700(GGG40-GGG70,FCD400-FCD700)

2. Surface treatment: Shot blast, painting; Heat treatment is optional;

3. Custom according to your drawing, specification or samples;

Gray iron HT200-350 (GG20-35, FC200-350);Ductile Iron QT400-QT700(GGG40-GGG70,FCD400-FCD700)

2. Surface treatment: Shot blast, painting; Heat treatment is optional;

3. Custom according to your drawing, specification or samples;

4: CNC machining according to your drawing

|

Material

|

Gray Iron Casting/Ductile Iron Casting

|

|

|

|

|||

|

Process

|

Resin sand casting/shell mold casting/lost foam casting + CNC machining

|

|

|

|

|||

|

Casting Tolerance

|

CT9-10 for Machine Molding Process,

CT8-9 for Shell Molding and Lost Foam Molding Casting Process CT10-11 for Manual Molding Sand casting Process |

|

|

|

|||

|

Casting surface roughness

|

Ra 12.5-25 um

|

|

|

|

|||

|

Casting weight range

|

0.5kg to 10tons per piece

|

|

|

|

|||

|

Casting Size

|

As Requirement/As drawing

|

|

|

|

|||

|

Machining surface roughness

|

As Requirement

|

|

|

|

|||

|

Material standard

|

GB, ASTM, AISI, DIN, BS, JIS, NF, AS, AAR

|

|

|

|

|||

|

Surface treatment

|

KTL (E-coating), Zinc plating, Mirror Polishing, Sand Blasting, Acid pickling, black oxide, Painting, Hot galvanizing, Powder coating, and Nickel plating.

|

|

|

|

|||

|

Service available

|

OEM & ODM

|

|

|

|

|||

|

Quality control/Testing facility

|

spectrometer,tensile test, hardness test, metallography microscope. Ultrasonic test, 100% inspection

|

|

|

|

|||

|

Application

|

Train & railway, automobile& truck, construction machinery, forklift, agricultural machinery, shipbuilding, petroleum

machinery,construction, valves and pumps, electric machine, hardware, power equipment, and so on. |

|

|

|

|||

Mechanical character

|

Grey Iron Grade in GB 9439 Gray iron Castings

|

|

|

|

|||

|

Gray Iron Grade

|

Single Specimen

Tensile Strength

σb≥/Mpa

|

Wall Thickness

/mm

|

Tensile Strength

σb≥/Mpa

|

|||

|

HT100

|

100

|

>2.5~10

|

130

|

|||

|

|

|

>10~20

|

100

|

|||

|

|

|

>20~30

|

90

|

|||

|

|

|

>30~40

|

80

|

|||

|

HT150

|

150

|

>2.5~10

|

175

|

|||

|

|

|

>10~20

|

145

|

|||

|

|

|

>20~30

|

130

|

|||

|

|

|

>30~40

|

120

|

|||

|

HT200

|

200

|

>2.5~10

|

220

|

|||

|

|

|

>10~20

|

195

|

|||

|

|

|

>20~30

|

170

|

|||

|

|

|

>30~40

|

160

|

|||

|

HT250

|

250

|

>2.5~10

|

270

|

|||

|

|

|

>10~20

|

240

|

|||

|

|

|

>20~30

|

220

|

|||

|

|

|

>30~40

|

200

|

|||

|

HT300

|

300

|

>10~20

|

290

|

|||

|

|

|

>20~30

|

250

|

|||

|

|

|

>30~40

|

230

|

|||

|

HT350

|

350

|

>10~20

|

340

|

|||

|

|

|

>20~30

|

290

|

|||

|

|

|

>30~40

|

260

|

|||

|

Ductile Iron Grade in GB1348 Ductile Iron Castings

|

|

|

|

|

||||

|

Iron Grade

|

Wall Thickness

/mm

|

Tensile Strength(Min Mpa)

|

Yield Strength(Min Mpa)

|

elongation

% Min

|

||||

|

QT400-18A

|

>30~60

|

390

|

250

|

18

|

||||

|

|

>60~200

|

370

|

240

|

12

|

||||

|

QT400-15A

|

>30~60

|

390

|

250

|

15

|

||||

|

|

>60~200

|

370

|

240

|

12

|

||||

|

QT500-7A

|

>30~60

|

450

|

300

|

7

|

||||

|

|

>60~200

|

420

|

290

|

5

|

||||

|

QT600-3A

|

>30~60

|

600

|

360

|

3

|

||||

|

|

>60~200

|

550

|

430

|

1

|

||||

|

QT700-2A

|

>30~60

|

700

|

400

|

2

|

||||

|

|

>60~200

|

650

|

380

|

1

|

||||

|

Gray Iron Material Grades

|

|

|

|

|

|

|

|

|

||||||||

|

Country

|

Standard

|

Equivalent Grades of Grey Iron (Gray Cast Iron)

|

|

|

|

|

|

|

||||||||

|

ISO

|

ISO 185

|

100

|

150

|

200

|

250

|

300

|

350

|

-

|

||||||||

|

China

|

GB 9439

|

HT100

|

HT150

|

HT200

|

HT250

|

HT300

|

HT350

|

-

|

||||||||

|

USA

|

ASTM A48

|

-

|

NO.20

|

NO.30

|

NO.35

|

NO.40

|

NO.50

|

NO.55

|

||||||||

|

|

|

|

NO.25

|

|

|

NO.45

|

|

NO.60

|

||||||||

|

Germany

|

DIN 1691

|

GG10

|

GG15

|

GG20

|

GG25

|

GG30

|

GG35

|

GG40

|

||||||||

|

Austria

|

|

|

|

|

|

|

|

|

||||||||

|

European

|

EN 1561

|

EN-GJL-100

|

EN-GJL-150

|

EN-GJL-200

|

EN-GJL-250

|

EN-GJL-300

|

EN-GJL-350

|

|

||||||||

|

Japan

|

JIS G5501

|

FC100

|

FC150

|

FC200

|

FC250

|

FC300

|

FC350

|

-

|

||||||||

|

Italy

|

UNI 5007

|

G10

|

G15

|

G20

|

G25

|

G30

|

G35

|

-

|

||||||||

|

France

|

NF A32-101

|

-

|

FGL150

|

FGL200

|

FGL250

|

FGL300

|

FGL350

|

FGL400

|

||||||||

|

UK

|

BS 1452

|

100

|

150

|

200

|

250

|

300

|

350

|

-

|

||||||||

|

India

|

IS 210

|

-

|

FG150

|

FG200

|

FG260

|

FG300

|

FG350

|

FG400

|

||||||||

|

Spain

|

UNF

|

-

|

FG15

|

FG20

|

FG25

|

FG30

|

FG35

|

-

|

||||||||

|

Belgium

|

NBN 830-01

|

FGG10

|

FGG15

|

FGG20

|

FGG25

|

FGG30

|

FGG35

|

FGG40

|

||||||||

|

Australia

|

AS 1830

|

-

|

T150

|

T220

|

T260

|

T300

|

T350

|

T400

|

||||||||

|

Sweden

|

SS 14 01

|

O110

|

O115

|

O120

|

O125

|

O130

|

O135

|

O140

|

||||||||

|

Norway

|

NS11 100

|

SJG100

|

SJG150

|

SJG200

|

SJG250

|

SJG300

|

SJG350

|

-

|

||||||||

|

Ductile /Nodular Cast Iron Material Grades

|

|

|

|

|

|

|

|

|

||||||||

|

Country

|

Standard

|

Equivalent Grades of Ductile iron (SG Iron, Nodular Graphite Iron)

|

|

|

|

|

|

|

||||||||

|

ISO

|

ISO 1083

|

400-15

|

450-10

|

500-7

|

600-3

|

700-2

|

800-2

|

900-2

|

||||||||

|

|

|

400-18

|

|

|

|

|

|

|

||||||||

|

China

|

GB 1348

|

QT400-18

|

QT450-10

|

QT500-7

|

QT600-3

|

QT700-2

|

QT800-2

|

QT900-2

|

||||||||

|

USA

|

ASTM A536

|

60-40-18

|

60-42-10

|

70-50-05

|

80-55-06

|

100-70-03

|

120-90-02

|

—

|

||||||||

|

|

|

|

65-45-12

|

|

80-60-03

|

|

|

|

||||||||

|

Germany

|

DIN 1693

|

GGG40

|

—

|

GGG50

|

GGG60

|

GGG70

|

GGG80

|

—

|

||||||||

|

Austria

|

|

|

|

|

|

|

|

|

||||||||

|

European

|

EN 1563

|

EN-GJS-400-15

|

EN-GJS-450-10

|

EN-GJS-500-7

|

EN-GJS-600-3

|

EN-GJS-700-2

|

EN-GJS-800-2

|

EN-GJS-900-2

|

||||||||

|

|

|

EN-GJS-400-18

|

|

|

|

|

|

|

||||||||

|

Italy

|

UNI 4544

|

GS370-17

|

GS400-12

|

GS500-7

|

GS600-2

|

GS700-2

|

GS800-2

|

—

|

||||||||

|

France

|

NF A32-201

|

FGS370-17

|

FGS400-12

|

FGS500-7

|

FGS600-2

|

FGS700-2

|

FGS800-2

|

—

|

||||||||

|

UK

|

BS 2789

|

400/17

|

420/12

|

500/7

|

600/7

|

700/2

|

800/2

|

900/2

|

||||||||

Details Images

Hot Searches