- Product Details

- {{item.text}}

Quick Details

-

Power:

-

13KW

-

Weight:

-

1000 KG

-

Dimension(L*W*H):

-

2.5*1.5*3.2(m)

-

Marketing Type:

-

Hot Product 2024

-

Product name:

-

Wheat Flour Mill

-

Application:

-

Flour Production Industry

-

Raw material:

-

Wheat Maize Corn Soya Grains

-

Final products:

-

Super Fine Flour

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Jianxin

-

Voltage:

-

180V--430V & others

-

Power:

-

13KW

-

Weight:

-

1000 KG

-

Dimension(L*W*H):

-

2.5*1.5*3.2(m)

-

Marketing Type:

-

Hot Product 2024

-

Product name:

-

Wheat Flour Mill

-

Application:

-

Flour Production Industry

-

Raw material:

-

Wheat Maize Corn Soya Grains

-

Final products:

-

Super Fine Flour

|

Model |

Power |

Power Consumed Of One Ton Flour |

Capacity |

Overall Dimension(L*W*H) |

|

No. |

(KW) |

(KW/H) |

(Ton/24h) |

(M) |

|

3 |

60 |

25~32 |

30 |

25*7.5*12 |

|

4 |

80 |

36~45 |

40 |

25*7.5*12 |

|

5 |

150 |

55~65 |

50 |

25*7.5*12 |

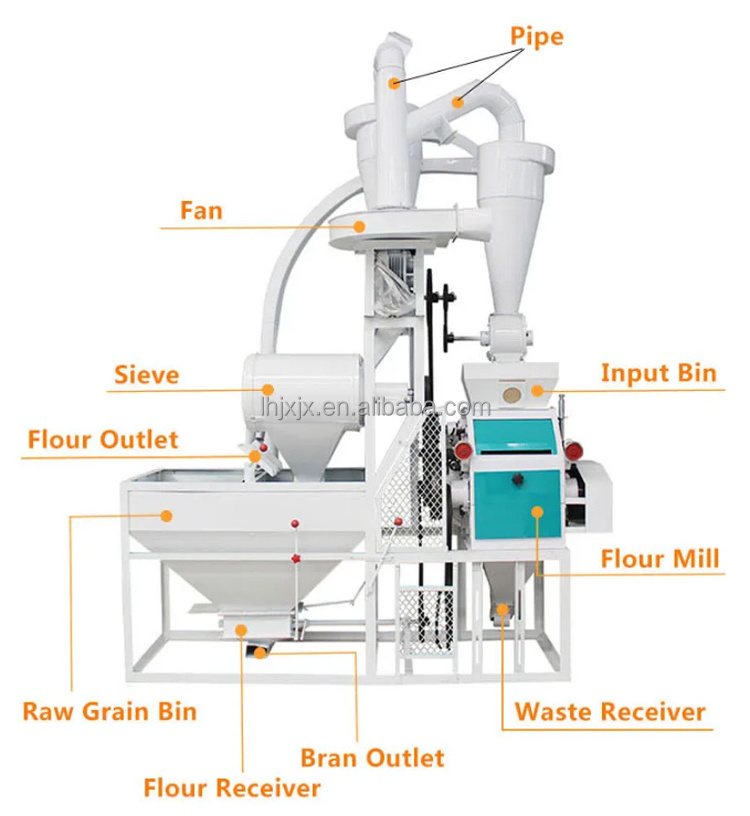

50 TPD wheat flour mill procudtion line

Wheat flour production line can be divided into 3 parts:

1. Cleaning part

T o clean out the light impurities from raw wheat, such as, dust, stone, metals, insect , bitten wheat and etc.. The main machines are vibrating screening, destoner, magnetic separator, dampening. This section is to prepare for milling part and to protect the milling system machines as well.

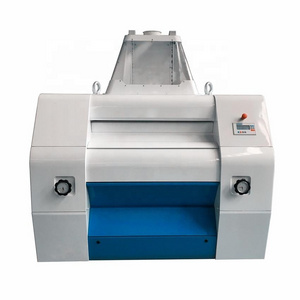

2. Milling part

To mill the grain and separate the flour, bran and other by-products:

(1) Mill: mill the grain to break the integrity by the roller moving.

(2) Sifter: to separate the flour,bran and other by-product, also separate large size and small size to ensure flour quality .

The main machines are flour mill,sifter,bran beater and so on.

3. Packing part

C an be manual or automatic weighting and packing 5kg,10kg,25kg,50kg bags.

4. PLC controlling system(optional)

To control the whole set of production line to work well and indicating the process of working .

Pre-sales & Scheme

We provide professional design according to the requirements of your products. We will offer you reasonable recommendations and optimal solutions to guarantee the overall performance of the machine so as to ensure your entire production process and the quality of your products.

Equipment Installation and Training

We have professional installation technicians provide installation and training services for your workers. It will be helpful to guarantee the normal operation of the equipment and reduce its downtime.

F i xing and Services

We have specialized technology department and after-sales service department to provide you with reliable pre-sales service and timely thoughtful after-sales service.We will do regular examinations to the equipment and offer you guidance on the equipment operation if you need. Spare Parts Supply

In your first order, we will send you some wearing parts available for two-years operation of the equipment. Online procurement for parts is available when the equipment is in operation.We will supply wearing parts with factory price for old customers.