Stable wooden package protects machine from strike and damage.

Wound plastic film keeps machine out of damp and corrosion.

Fumigation-free package helps the smooth customs clearance.

The big size machine will be fixed in container without package.

- Product Details

- {{item.text}}

Quick Details

-

Power (kW):

-

16Kw

-

Weight (KG):

-

980 KG

-

System flow:

-

50~2000g/min

-

Raw material:

-

200~1000cps (under operating temperature)

-

Storage tank volume:

-

45L*2

-

Heating power:

-

1000W*2 (with heating cable, no refrigeration)

-

Heating temperature:

-

0℃~75℃

-

System feeding:

-

Diaphragm pump feed

-

Infusion gun:

-

Initial collision + air assisted mixing, air cleaning gun

-

System ratio:

-

1:1~1:5 (variable ratio)

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

BOBO

-

Machine Type:

-

PU foam machine

-

Power (kW):

-

16Kw

-

Weight (KG):

-

980 KG

-

System flow:

-

50~2000g/min

-

Raw material:

-

200~1000cps (under operating temperature)

-

Storage tank volume:

-

45L*2

-

Heating power:

-

1000W*2 (with heating cable, no refrigeration)

-

Heating temperature:

-

0℃~75℃

-

System feeding:

-

Diaphragm pump feed

-

Infusion gun:

-

Initial collision + air assisted mixing, air cleaning gun

-

System ratio:

-

1:1~1:5 (variable ratio)

Product Description

Pipe-In-Pipe Continuous Forming System

Our company recently launched the CZG1(3) pipe-in-pipe continuous forming system, which is mainly used in PPR pipes, copper pipes, stainless steel pipes, galvanized pipesand other insulation layers and shells for one-time continuous foaming molding, with good insulation effect and high degree of automation. ,high productivity.

* Advanced forming welding technology can be adapted to products of different models and specifications.

* The advanced material pump protection liquid circulation system and feed protection circulation system solve the application

problems of easily crystallized materials or air-sensitive materials.

* High-precision ratio output, multiple recipe settings and memory functions make the system more convenient and quicker to deal

with the production of products of different specifications.

* Digital control, high degree of automation, man-machine friendly interface and easy operation.

* The new mixing method makes the mixing more even, the product quality is good, and the consistency is high.

* Patented technology no-cleaning gun, daily maintenance is simpler.

* Advanced scrap recycling technology to reduce waste.

* Advanced forming welding technology can be adapted to products of different models and specifications.

* The advanced material pump protection liquid circulation system and feed protection circulation system solve the application

problems of easily crystallized materials or air-sensitive materials.

* High-precision ratio output, multiple recipe settings and memory functions make the system more convenient and quicker to deal

with the production of products of different specifications.

* Digital control, high degree of automation, man-machine friendly interface and easy operation.

* The new mixing method makes the mixing more even, the product quality is good, and the consistency is high.

* Patented technology no-cleaning gun, daily maintenance is simpler.

* Advanced scrap recycling technology to reduce waste.

Specification

System configuration (standard)

System host: 1 set

Conveyor system: 1 set

Forming welding system: 1 set

Material console: 1 set

Perfusion gun: 1 piece

Conveying insulation pipe group: 1 set of 3 meters

Random spare parts and tools: 1 set

Dimensions and site requirements (net)

Host appearance: 800mm×800mm×1600mm (length×width×height)

Venue requirements: 20 meters long x 3 meters wide (including operator )space and passage)

System host: 1 set

Conveyor system: 1 set

Forming welding system: 1 set

Material console: 1 set

Perfusion gun: 1 piece

Conveying insulation pipe group: 1 set of 3 meters

Random spare parts and tools: 1 set

Dimensions and site requirements (net)

Host appearance: 800mm×800mm×1600mm (length×width×height)

Venue requirements: 20 meters long x 3 meters wide (including operator )space and passage)

|

No

|

Item

|

Technical parameter

|

|

1

|

System ratio

|

1:1~1:5 (variable ratio)

|

|

2

|

Raw material viscosity

|

200~1000cps (under operating temperature)

|

|

3

|

System flow

|

50~2000g/min

|

|

4

|

power supply

|

Single phase 220V/ 50HZ /9KW

|

|

5

|

System raw material pressure

|

≤2Mpa (285psi)

|

|

6

|

Gas source

|

0.5-0.8MPa(70~120psi)≥0.5m3/min

|

|

7

|

Storage tank volume

|

45L×2

|

|

8

|

Heating power of storage tank

|

1000W×2 (with heating cable, no refrigeration)

|

|

9

|

Heating temperature range

|

0℃~75℃

|

|

10

|

System feeding method

|

Diaphragm pump feed

|

|

11

|

Infusion gun function

|

Initial collision + air assisted mixing, air cleaning gun

|

|

12

|

Working flow of perfusion gun

|

0~2Kg/min

|

|

13

|

Production speed

|

0-8 m/min

|

Packing and Shipping

Packaging:

Shipping:

For LCL, we cooperated with reputable logistics team to send machine to sea port speedily and safely.

For FCL, we get the container and do container loading by our skillful workers carefully.

For forwarders, we have professional and long-term cooperated forwarders who can handle the shipment smoothly. Also we would like to have seamless cooperation with your forwarder at your convenience.

For FCL, we get the container and do container loading by our skillful workers carefully.

For forwarders, we have professional and long-term cooperated forwarders who can handle the shipment smoothly. Also we would like to have seamless cooperation with your forwarder at your convenience.

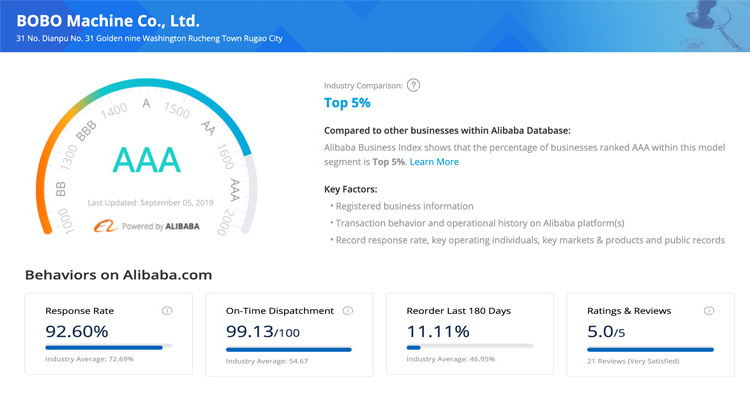

Trade Assurance

FAQ

1. Q: What is the power supply of the machine?

A: The standard power supply in china is 380V, 3P, 50Hz. We also can customized accordingly.

2. Q: What information should the customer provide to get an accurate quotation from us?

A: The customer should provide the related technical requirements, drawings, pictures, industrial voltage, planned output, etc

3. Q: What is the payment term A: The payment term is 30% down payment, and 70% before shipment(T/T mode), we also accept other payment term, like L/C, DA, D/P etc

4. Q: What is the delivery time?

A: Normally the delivery time of the machine is 30 days after receive down payment.

5. Q: What is the warrantee period of the machine?

A: The warrantee period is one year since the date of B/L.

A: The standard power supply in china is 380V, 3P, 50Hz. We also can customized accordingly.

2. Q: What information should the customer provide to get an accurate quotation from us?

A: The customer should provide the related technical requirements, drawings, pictures, industrial voltage, planned output, etc

3. Q: What is the payment term A: The payment term is 30% down payment, and 70% before shipment(T/T mode), we also accept other payment term, like L/C, DA, D/P etc

4. Q: What is the delivery time?

A: Normally the delivery time of the machine is 30 days after receive down payment.

5. Q: What is the warrantee period of the machine?

A: The warrantee period is one year since the date of B/L.

Hot Searches