- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380-440

-

Power:

-

Depends on the final production line

-

Dimension(L*W*H):

-

Depends on the final production line

-

Weight:

-

depends the final producti line on

-

After Warranty Service:

-

Video technical support, Online support, Field maintenance and repair service

-

Local Service Location:

-

Egypt, Viet Nam, Saudi Arabia, India, Russia, South Africa

-

Certification:

-

ce

-

After-sales Service Provided:

-

Video technical support, Field installation, commissioning and training, Field maintenance and repair service, Online support, Engineers available to service machinery overseas

-

Platen Size:

-

1200 x 400 mm

-

Forming Cycle:

-

≤ 25 Stroke / min

-

Max. Pressure:

-

40 Ton, by Servo Drived Crank Arm

-

No. of Molds:

-

3pcs / platen (based on 12-egg carton)

-

Max. Product Height:

-

80 mm

-

Heating Type:

-

Electric

-

Control By:

-

PLC + Touchscreen

Quick Details

-

Production Capacity:

-

3500 ~ 7000 pcs/hr (30 egg tray)

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

HGHY

-

Voltage:

-

380-440

-

Power:

-

Depends on the final production line

-

Dimension(L*W*H):

-

Depends on the final production line

-

Weight:

-

depends the final producti line on

-

After Warranty Service:

-

Video technical support, Online support, Field maintenance and repair service

-

Local Service Location:

-

Egypt, Viet Nam, Saudi Arabia, India, Russia, South Africa

-

Certification:

-

ce

-

After-sales Service Provided:

-

Video technical support, Field installation, commissioning and training, Field maintenance and repair service, Online support, Engineers available to service machinery overseas

-

Platen Size:

-

1200 x 400 mm

-

Forming Cycle:

-

≤ 25 Stroke / min

-

Max. Pressure:

-

40 Ton, by Servo Drived Crank Arm

-

No. of Molds:

-

3pcs / platen (based on 12-egg carton)

-

Max. Product Height:

-

80 mm

-

Heating Type:

-

Electric

-

Control By:

-

PLC + Touchscreen

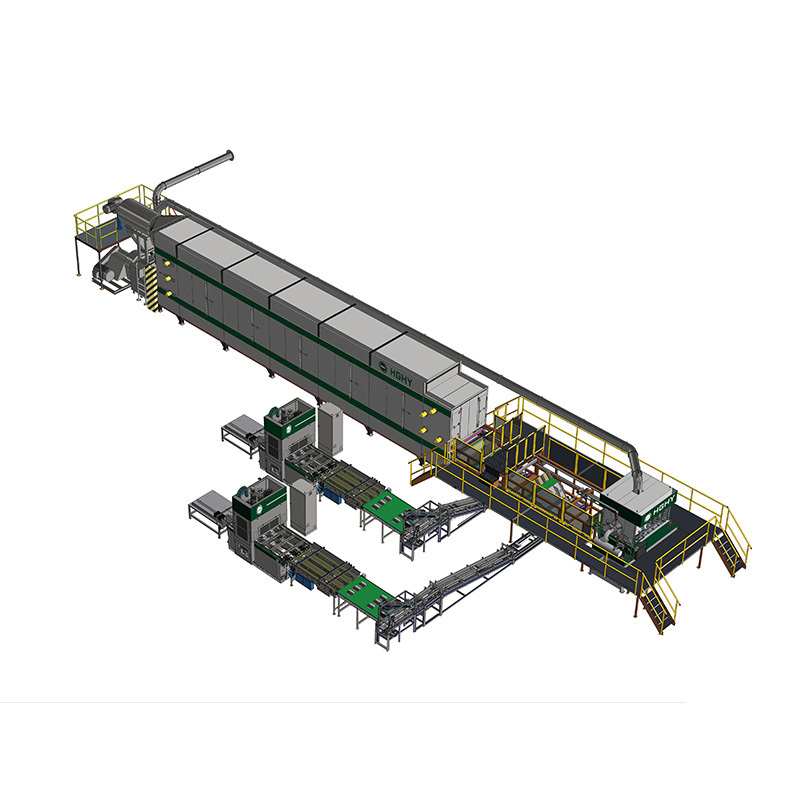

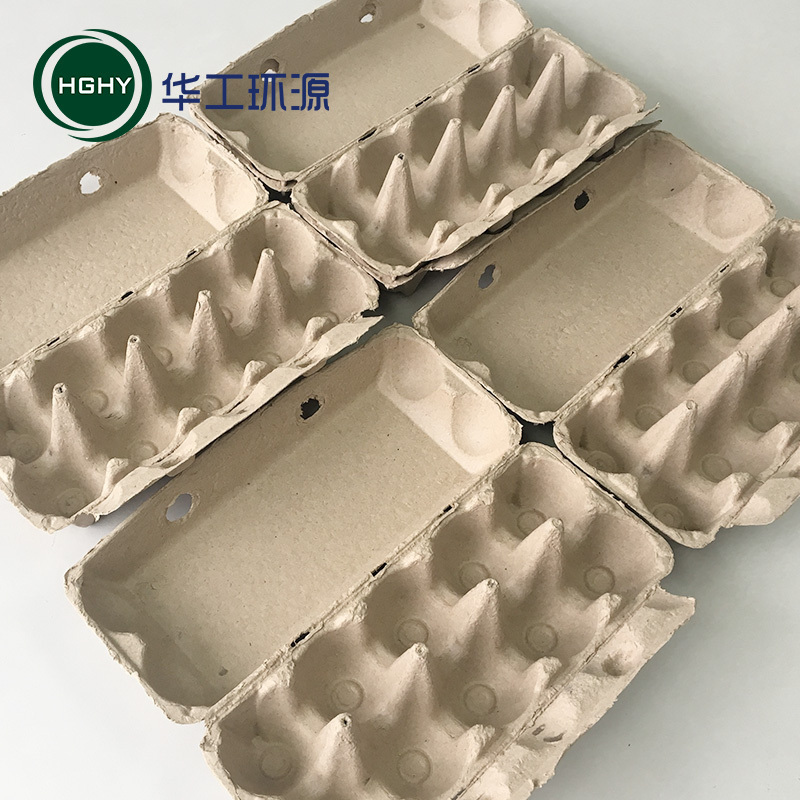

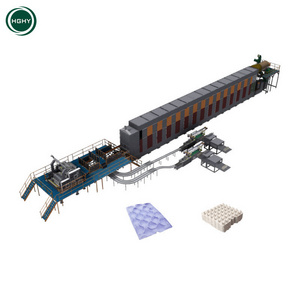

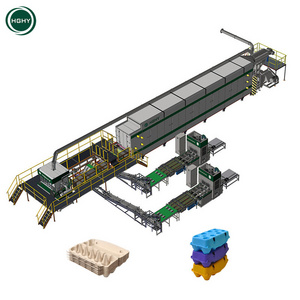

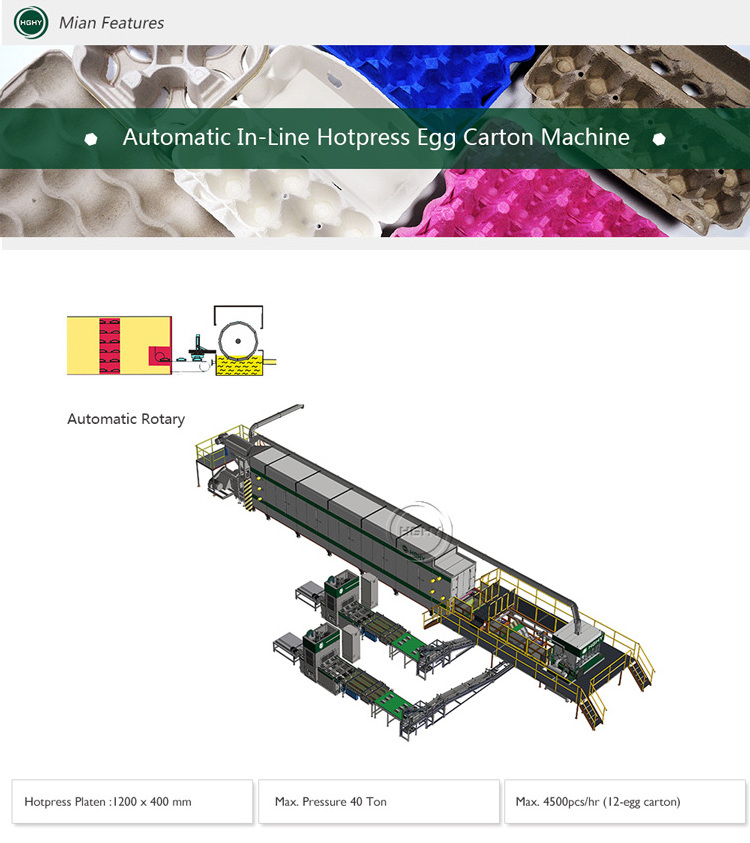

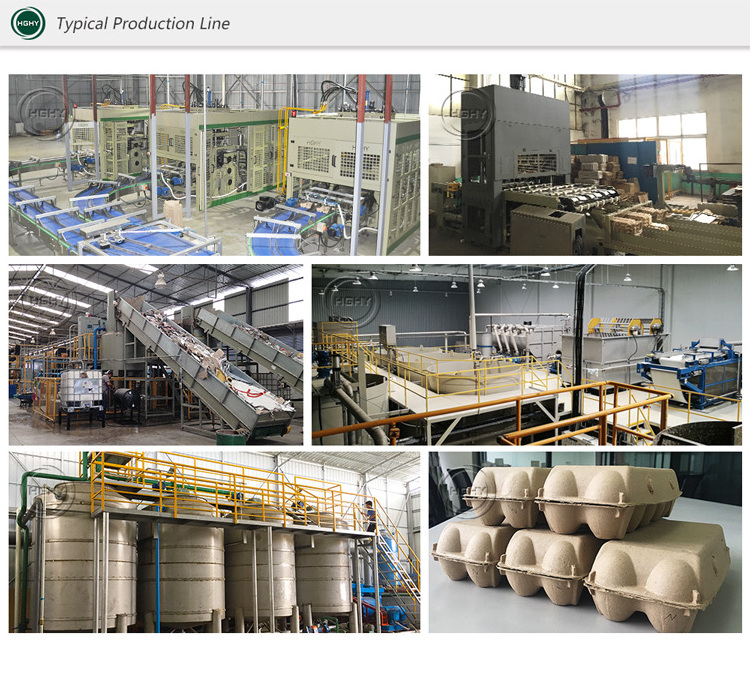

The automatic in-line hotpress egg carton machine is mainly applied for producing egg packaging cartons, drinking cup carrier trays, bottle trays and products which require afterpress for better shapes after the drying process . Pulp molding production line with automatic in-line hotpress egg carton machine as the main system has the following features:

- Fully automatic system replacing manual operation

- Excellent performance of rotary forming technology

- Highly efficient 6-pass drying line specially designed for egg box

- Match with auto conveying and auto hotpress system

| Mian Specifications | |

| Model. | ZRY40-12040 |

| Structure |

Auto Feed Conveyor System x1,

Fully Auto Hotpress Machine x1, Auto Discharge Conveyor and Stacker x1. |

| Platen Size | 1200 x 400 mm |

| Max. Pressure | 40 Ton, by Servo Drived Crank Arm |

| Forming Cycle | ≤ 25 Stroke / min |

| No. of Molds | 3pcs / platen (based on 12-egg carton) |

| Max. Product Height | 80 mm |

| Heating Type | Electric |

| Control By | PLC + Touchscreen |

| Designed Capacity | 3500 - 7000 pcs/hr (based on 12-egg carton) |

| Remarks |

* The above specification is for reference only, due to continuous technology development, data will be updated

from time to time.

we are able to provide customized solution according to

specific requirements from customer.

will provide more effective help and supports for you. |

Who We Are

* The one and only company among pulp molding industry in China, who drew up several industrial standards;

* The one and only company among pulp molding industry in China, who first produced and installed high speed production line for customer.

* HGHY is the first ever one of its kind to develop the de-molding angle and large capacity thermoforming automatic machines.

* HGHY is the first ever one of its kind to develop the full-automatic thermoforming production line of egg carton.( and also for fruit tray and cup tray.)

* As the partner of the famous university, SCUT, HGHY offers excellent R&D methods and technology support with a strong, stable R & D team to ensure its leading technological position in the pulp industry.