Packaging:

1, Bundles Packing: Inside: packed with plastic protective film to protect each piece. Outside: Wrap to be bundles by waterproof

craft paper or EPE film.

2, Carton Packing: Inside: Each pcs pack in one plastic bag. Outside: Numbers of quantity put in one carton.

3, Wood Pallet Packing: Inside: Bundles or cartons packing; Outside: Numbers of bundles or cartons laden on one wood pallet.

4, Customized Packing As Clients Request is Available.

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

Customized according to customer drawings

-

Shape:

-

Customized according to customer drawings

-

Material:

-

According to customer requirements, Carbon steel, alloy steel, stainless steel

-

Chemical Composition:

-

Customized according to customer drawings

-

Item Name:

-

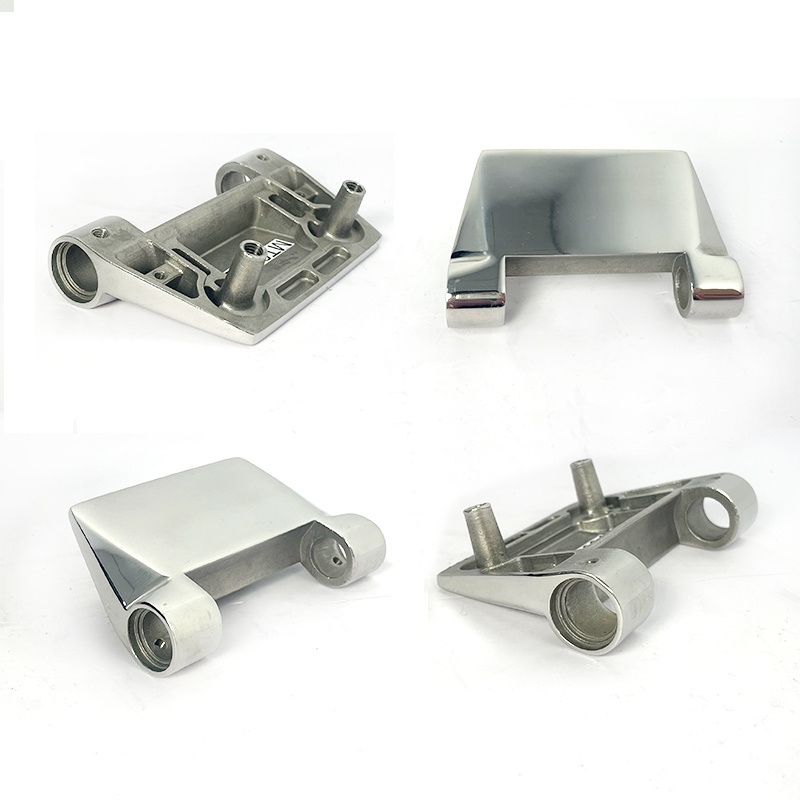

Steel Metal Custom Investment Die Casting Parts

-

Manufacturing Process:

-

Investment casting or Lost wax casting

-

Casting Tolerance:

-

CT4-6 for Investment casting or CT6-9 for Lost wax casting

-

Machining Process:

-

Lost wax casting/Investment casting + cnc machining+surface treatment

-

Surface Treatment:

-

Powder coating,Painting, or as customer required

-

Rough Surface Roughness:

-

Ra 3.2-12.5 for investment casting or Ra 12.5-25 for lost wax casting

-

Package for die casting parts:

-

Multilayer wooden box/pallet, with big plastic bag inside

-

Lead Time:

-

45 days of Steel Metal Custom Investment Die Casting Parts

-

Service:

-

Steel Metal Custom Investment Die Casting Parts

Quick Details

-

Application:

-

According to customer requirements

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

custom logo

-

Model Number:

-

Customized according to customer drawings

-

Shape:

-

Customized according to customer drawings

-

Material:

-

According to customer requirements, Carbon steel, alloy steel, stainless steel

-

Chemical Composition:

-

Customized according to customer drawings

-

Item Name:

-

Steel Metal Custom Investment Die Casting Parts

-

Manufacturing Process:

-

Investment casting or Lost wax casting

-

Casting Tolerance:

-

CT4-6 for Investment casting or CT6-9 for Lost wax casting

-

Machining Process:

-

Lost wax casting/Investment casting + cnc machining+surface treatment

-

Surface Treatment:

-

Powder coating,Painting, or as customer required

-

Rough Surface Roughness:

-

Ra 3.2-12.5 for investment casting or Ra 12.5-25 for lost wax casting

-

Package for die casting parts:

-

Multilayer wooden box/pallet, with big plastic bag inside

-

Lead Time:

-

45 days of Steel Metal Custom Investment Die Casting Parts

-

Service:

-

Steel Metal Custom Investment Die Casting Parts

|

Item Name:

|

Precision Machining Powder Coating Sus304l Stainless Steel Valve With Competitive Price

|

|

General Products Application/Service Area:

|

Train & railway, automobile& truck, construction machinery, forklift, agricultural machinery, shipbuilding, petroleum machinery,construction, valve and pumps, electric machine, hardware, power equipment and so on.

|

|

Main blank Process:

|

Lost wax casting/Investment casting + cnc machining+surface treatment

|

|

Blanks Tolerance -Casting Tolerance:

|

CT4-6 for Investment casting or CT6-9 for Lost wax casting

|

|

Applicable Material for casting:

|

Carbon steel, alloy steel, stainless steel;sus304,sus304l,sus316,sus316l,4140,2Cr12,20CrMo,40CrMo

|

|

Casting Blank Size:

|

Max linear size: 1200mm, Max diameter size: 600mm

|

|

Casting Weigh Range:

|

0.1-90kg

|

|

Applicable Machining Process:

|

CNC Machining/ Lathing/ Milling/ Turning/ Boring/ Drilling/ Tapping/ Grinding and etc.

|

|

Machined Surface Quality:

|

Ra 3.2-12.5 for investment casting or Ra 12.5-25 for lost wax casting

|

|

Machining Tolerance:

|

From 0.005mm-0.01mm-0.1mm for powder coating sus304L stainless steel valve

|

|

Applicable Finish Surface Treatment:

|

Shot/sand blast, polishing, Primer Painting , Powder coating, ED- Coating, Finish Painting as customers request etc

|

|

MOQ for mass production:

|

For casting parts: 100pcs

For machining: 50pcs |

|

Lead Time:

|

About 50 days from the receipt date for powder coating sus304L stainless steel valve

|

|

1. Marterial percentage

|

alloy steel:45%

carbon steel:35% stainless steel:10% iron:10% |

|

2. Casting weight percentage

|

0.1-5kg:40%

5-20kg:30% 20-40kg:20% above 40kg:10% |

|

3. Industry percentage

|

Components for train & railway: 25%

Components for automobile & truck: 30% Components for construction machinery & forklift: 25% Components for agricultural machinery: 10% Other machinery compponents: 10% |

|

4. Globa market share

|

United States:30%

Europe:35% Japan& Korea:15% Domestic market:15% Other:5% |

|

5. Production capacity

|

Production Capacity: 20,000 tons / year

The Current Production Output: 15,000 tons / year Open Capacity Percentage: 25% |

1. Process Flow Diagrams

2. Control Plan

3. Process FMEA

4. Casting Process Instruction

5. Solidification Simulation Report

6. Heat Treatment Work Instruction

7. Casting Final Quality Control WI

8. Visual Inspection VI For Surface Irregularities

1. Process Flow Diagrams

2. Control Plan

3. Process FMEA

4. Machining Process Instruction

5. Gauge List And Validation Plan

6. Final Quality Control WI

1. Material Test Report(A)

2. Material Test Report(B)

3. Magnetic Particle Inspection Report

4. Ultrasonic Examination Report

5. Radiographic Test Report

6. Destructive Test Report

7. Coating Test Report

8. Visual Inspection Report

9. Casting Inspection Report

1. Dimensional Inspection Report(A)

2. Dimensional Inspection Report(B)

3. CMM Report

* PPAP Checklist

* Measurement System Analysis Study

* Process Capability Studies

* Corrective Action Report(8D)

* Packaging Instruction

|

1. Chemical analysis

|

|

2. Tensile strength

|

|

3. Elongation rate

|

|

4. Shrinkage rate

|

|

5. Impact test

|

|

6. Harness test

|

|

7. Metallography

|

|

8.Non-destructive tests(including dye-penetrant, ultrasonic, magnetic particle and radiography)

|

|

9. Surface roughness test

|

|

10.CMM test

|

|

11.3D Scanning

|

Q 1. What do you do?

A: We are a professional manufacturer with over 15 years' export experience for designing and producing vehicle machinery parts.

Q 2. How can I get some samples?

A: If you need, we are glad to offer you samples for free, but the new clients are expected to pay the courier cost, and the charge will be deducted from the payment for formal order.

Q 3. Can you make casting according to our drawing?

A: Yes, we can make casting according to your drawing, 2D drawing, or 3D cad model. If the 3D cad model can be supplied, the development of the tooling can be more efficient. But without 3D, based on 2D drawing we can still make the samples properly approved.

Q 4. Can you make casting based on our samples?

A: Yes, we can make measurement based on your samples to make drawings for tooling making.

Q 5. What's your quality control device in house?

A: We have spectrometer in house to monitor the chemical property, tensile test machine to control the mechanical property and UT Sonic as NDT checking method to control the casting detect under the surface of casting.