- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

JSWintek

-

Dimension(L*W*H):

-

6058*2438*2591

-

Weight:

-

7550

-

Design Drawing:

-

31201

-

Water capacity:

-

21 100 Liters

-

Keywords:

-

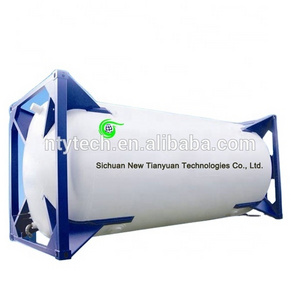

Cryogenic Liquid ISO Tank Container/Portable Tank

-

Product name:

-

Intermodal ISO Container UN T75

-

Application:

-

Cryogenic liquid storage and transportation

-

Technology:

-

High vacuum multi layer heat insulation

-

Advantage:

-

Low vaporization loss

-

MAWP:

-

1.6 MPa

-

Filling ratio:

-

95%/90%

-

Maximum payload:

-

28 450 kg

Quick Details

-

Capacity:

-

21.1 m3

-

Max Working Pressure(MPa):

-

1.6 MPa

-

Marketing Type:

-

New Product 2022

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

JSWintek

-

Dimension(L*W*H):

-

6058*2438*2591

-

Weight:

-

7550

-

Design Drawing:

-

31201

-

Water capacity:

-

21 100 Liters

-

Keywords:

-

Cryogenic Liquid ISO Tank Container/Portable Tank

-

Product name:

-

Intermodal ISO Container UN T75

-

Application:

-

Cryogenic liquid storage and transportation

-

Technology:

-

High vacuum multi layer heat insulation

-

Advantage:

-

Low vaporization loss

-

MAWP:

-

1.6 MPa

-

Filling ratio:

-

95%/90%

-

Maximum payload:

-

28 450 kg

Technical specifications

|

Type of product

|

Intermodal ISO Container UN T75 |

|

Medium

|

LN2/LO2/LAr |

|

MAWP.

|

1.6 MPa |

|

Water capacity |

21 100 Liters |

|

Tare mass ( Nominal ) |

7 550 kg (maximum tolerance 3%)

|

|

Filling ratio

|

95%/90% |

|

Maximum payload

|

28 450 kg |

|

M.P.G.M

|

36 000 kg |

|

Stacking

|

192 000 kg |

|

Design code

|

ISO1496-3 , IMDG , ADR , RID , ASME USDOT , CUTR |

|

Approvals

|

CCC, CSC |

|

Approval and inspection org

|

Lloyd's Register |

Inner vessel

|

Design code

|

ASME SECT. (Mandatory appendix 44) |

|

Material

|

Stainless steel

|

|

Design temperature

|

50 ℃ |

|

MDMT

|

-196 ℃ |

|

Baffles

|

Two transvers baffles

|

|

Surface treatment

|

Pickling

|

Out vessel

|

Material |

Carbon steel ( Stainless steel )

|

|

Design temperature

|

50 ℃ |

|

MDMT

|

-40 ℃ |

|

Surface treatment

|

Shot blast to SA 21/2

|

FRAME

|

Size

|

20' 1CC ISO container

|

|

Dimensions

|

6,058 × 2,438 × 2,591mm(L × W × H)

|

|

Material

|

Low alloy steel

|

|

Upside walk path

|

No

|

|

Ladder

|

No

|

WELCOME TO VISIT US

JIANGSU WINTEK INDUSTRIAL TECHNOLOGY CO., LTD.

is an innovative enterprise which focus on design, manufacture, engineering, service and trading for cryogenic industrial gas equipment and chemical energy machinery, etc. We adopt and develop the latest technology in our involved industries, and simply most advanced and cost economical plant and equipment to our valuable customers.

We are committed to package design, production and sales of cryogenic air separation equipment, as well as professional supply and export services of air separation equipment, oxygen generator, nitrogen generator, cryogenic liquid storage and transportation equipment, gasifier vaporizer, gas compressor, turbine expander, heat exchanger, natural gas treatment equipment, natural gas liquefaction equipment, carbon dioxide recovery equipment, air dryer, etc. We are the first level supplier in the field of industrial gas and stream equipment in China.

VIEW MORE »

Q1. What are your main involved products?

A: (1) Cryogenic air separation plant industry (including cryogenic oxygen/nitrogen/argon gas/liquid production plant, oxygen/nitrogen liquefier, and the configured self-cleaning air filter, air pre cooler/chiller, turbine expander, brazed aluminum plate fin heat exchanger(BAHX), cryogenic liquid pump, etc.), and startup/maintenance service

(2) Cryogenic liquid tanks and vaporizers (including stationary vacuum powder insulation tank, stationary large flat bottom tank, mobile vacuum multi-layer tank, water bath/ambient vaporizer, etc.

(3) LNG plant

(4) Hydrogen generator

(5) Heat exchangers (tube and shell type, brazed aluminum type, coil tube type)

(6) Valves and instruments (cryogenic valves, anti-corrosion valves, pressure/differential pressure transmitter, RTD, etc.)

(7) Air dryer

(8) Air blower (centrifugal type, roots type, etc.)

(9) Screw/reciprocating gas compressors

(10) Cryogenic liquid pump

(11) Other industrial gas/stream/energy relating equipment sourcing and purchasing service from China as per customers’ inquiry.

Q2. What is your terms of payment?

A: T/T 30% as deposit, and 70% T/T or L/C at sign before delivery.

Q3. What is your terms of delivery?

A: EXW, FOB, CFR, CIF.

Q4. How about your delivery time?

A: Generally, it will take 2-12 months after contract effect and depends on the order details.

Q5. Can you produce according to the client's request ?

A: Yes, most products are nonstandard products and designed/fabricated as per customers’ specific technical requirements.

Q6: Why work with us?

A : (1) Over 20 years’ technical experience in cryogenic air separation industry

(2) International latest technology and full supply chain for industrial gas equipment

(3) One-stop channel to China industrial gas equipment

(4) Reliable and trustable supply chain management and project implementation