- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

Hdpe/Ldpe/Pe/Pp Resin Color Plastic Masterbatch

-

Application:

-

Blown Film /Moulding,Injection ,Extrusion,Casting,Wire Drawing

-

Carrier:

-

PP PE

-

Certification:

-

ISO 9001 SGS ROHS

-

Packing:

-

25kg PP Bag

-

Color:

-

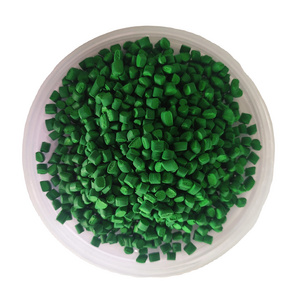

color,red,orange,yellow,green,blue,purpe,grey

-

Appearance:

-

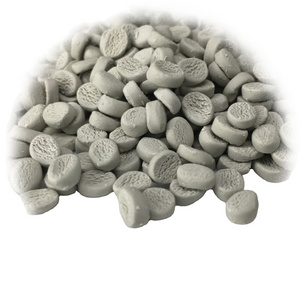

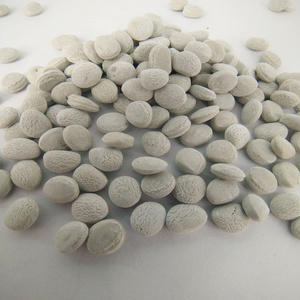

Small Granule

-

Other Name:

-

Masterbatch

-

Pigment Content:

-

10% 15% 20% 25% 30% 35% 40% 45% 50%

-

Light and weather resistance:

-

Grade 4-8

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

A FINE REFINEMENT

-

Model Number:

-

CM-01

-

Product name:

-

Hdpe/Ldpe/Pe/Pp Resin Color Plastic Masterbatch

-

Application:

-

Blown Film /Moulding,Injection ,Extrusion,Casting,Wire Drawing

-

Carrier:

-

PP PE

-

Certification:

-

ISO 9001 SGS ROHS

-

Packing:

-

25kg PP Bag

-

Color:

-

color,red,orange,yellow,green,blue,purpe,grey

-

Appearance:

-

Small Granule

-

Other Name:

-

Masterbatch

-

Pigment Content:

-

10% 15% 20% 25% 30% 35% 40% 45% 50%

-

Light and weather resistance:

-

Grade 4-8

Wholesale Price Color COLORANT Masterbatch for PE, PP, PLA Plastic Products

The pe/pp color masterbatch price is made of PE and PP as carriers, inorganic pigments and organic dyes with high-performance additives. The particles are uniform and beautiful in appearance, cylindrical or flat-round in shape, uniform in color, good dispersibility, stability and heat resistance. It is widely used in packaging film, pots, bottles, caps, pipes, containers, toys, household appliances, office supplies, automotive accessories and all kinds of construction. It is suitable for all kinds of blow moulding, extrusion, injection moulding, casting, wire drawing, chemical fibre and other processing fields.

Performance:

High concentration, high brightness, uniform dispersion and strong dyeing power.

Proportion of application:

The master batch and the raw resin can be mixed evenly at the ratio of 1:25-50 (depending on the specific requirements of the product). (Note: Resin containing moisture is used after drying)

Packing:

Paper-plastic composite bags, 25KG/bag net content, please store in the sun-shaded dry place.

Customization process:

Customers provide the required color template. We matches the color according to the template, makes the sample and then gives the customer the experiment. After the customer confirms, it produces according to the customer's order.

1. PE/PP Injection Molding (Box, Containers, Chairs, Crates, Buckets, Battery, cases, Hangers, etc.)

2. PE/PP Extrusion Molding (Sheet, Pipe, Wire & Cable, etc.)

3. PE Blow Molding (Medical & Cosmetic container, Lubricant & Paint container, etc)

4. PE Film (shopping bags, casting film, multilayer film, etc.)

5. PE Fiber (Carpet, Textiles, Upholstery, etc.)