- Product Details

- {{item.text}}

Quick Details

-

Function:

-

Metal Surface Grinding Polishing

-

Color:

-

Customer Requirement

-

Application:

-

Deburring

-

Product name:

-

Wheel Vibratory Polishing Machine

-

Motor:

-

Electric Vibrating Motor

-

Voltage:

-

380V 50Hz 3Phase/Customized

Quick Details

-

Place of Origin:

-

China

-

Power (kW):

-

1.9

-

Weight (KG):

-

600

-

Function:

-

Metal Surface Grinding Polishing

-

Color:

-

Customer Requirement

-

Application:

-

Deburring

-

Product name:

-

Wheel Vibratory Polishing Machine

-

Motor:

-

Electric Vibrating Motor

-

Voltage:

-

380V 50Hz 3Phase/Customized

Product Description

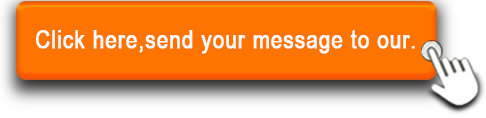

Wheel Polishing Machine

The vibrating polishing machine is designed for the grinding and polishing of automobile wheels.the abrasive movement track is more varied, and the polishing is more thorough and more efficient, using three vibration motors as the vibration source.It can also be used to polish larger hardware.

For this machine, if you have any questions,

please contact us

|

Model

|

Effective Diameter(mm)

|

Bowl Height(mm)

|

Bowl Volume(L)

|

Bowl Power(KW)

|

|

DZP-700

|

660

|

350

|

120

|

1.35

|

|

DZP-800

|

760

|

350

|

160

|

1.9

|

|

DZP-900

|

860

|

500

|

280

|

1.9

|

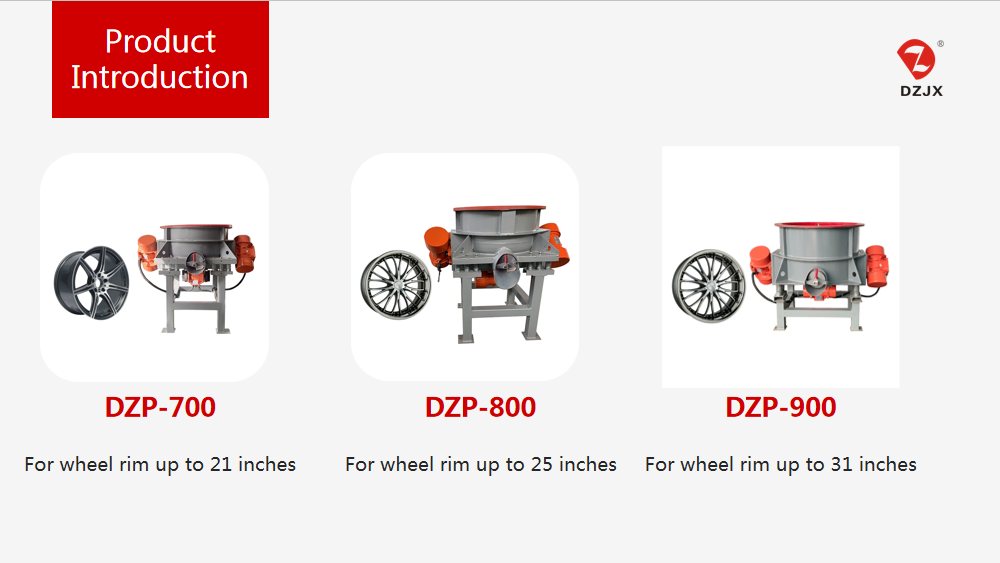

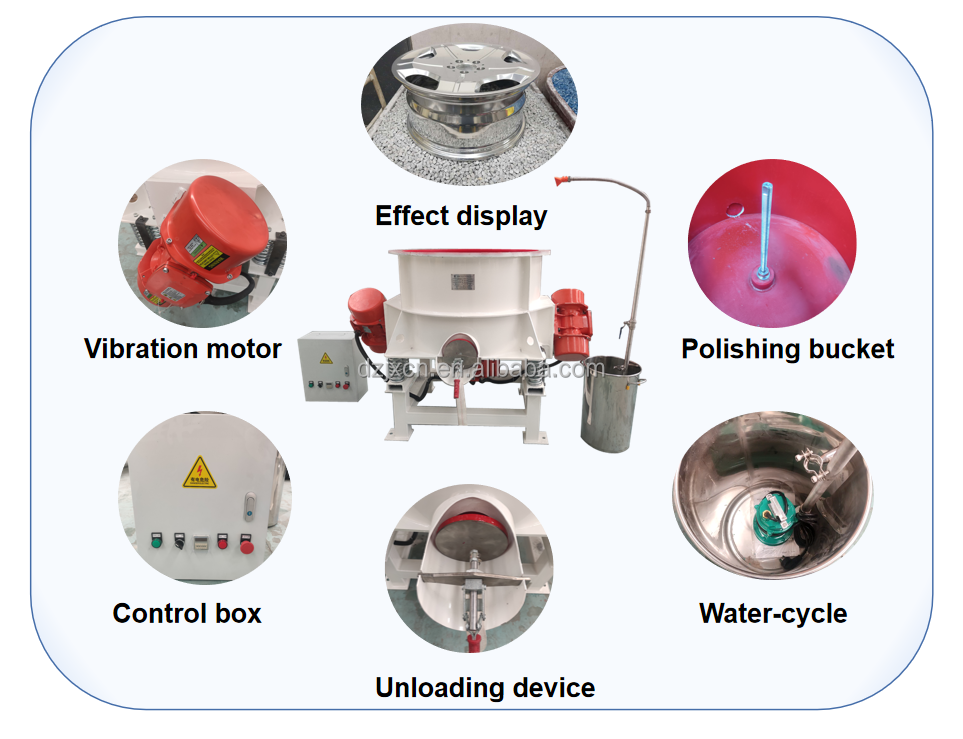

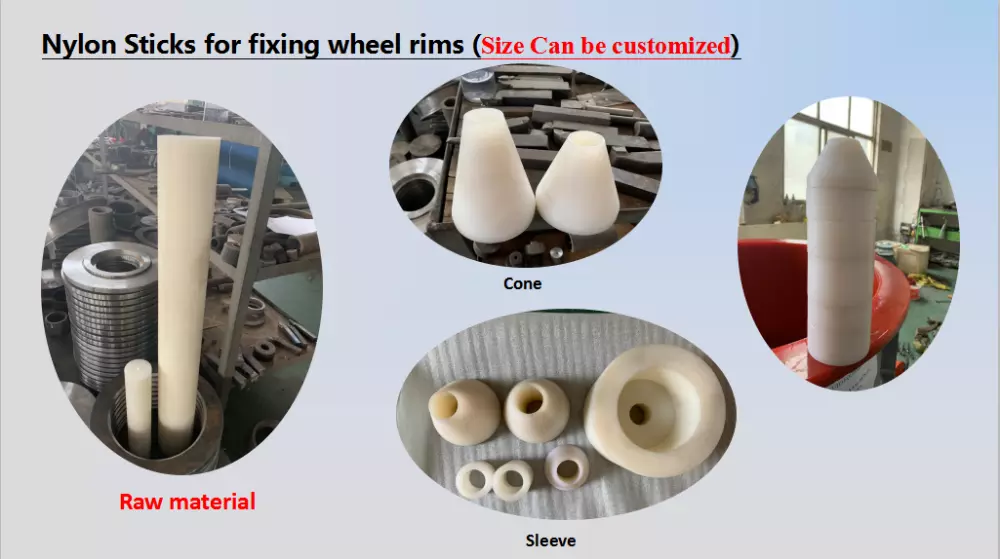

Alloy Wheel Rim Structure Automatic Polishing Machine

Vibratory Polish machine is composed of 1. Vibrating motor 2.Drum 3.Damping spring 4.Screw nut

5.Nylon sheath 6 Discharging valve 7. Drainage pipe 8.Supporting leg

please contact us

Why choose our wheel polishing machine?

1.It is proved that the vibration polisher can save 90% hand work in alloy wheel polishing.

2.It is suitable for surface finish processing of metal or non-metal workpieces including deburring, chamfering, derusting oxidation layer.

please contact us

Display of wheel polishing results for motorcycles, cars, and trucks

Detailed Images

How to choose a polishing medium?

The surface situation and cleaning situation of work piece has great influence to polishing media choosing and polishing time.Following are the polishing media that suggested by our engineer.

please contact us

|

Work piece

|

Coarse polish

|

Fine polish

|

Super fine polish

|

|

|

Middle polish

|

|

|

|

Burr and rag

|

Resin (particle size 10*10mm)

|

High alumina or high frequency porcelain (particle size 4mm)

|

Zirconia or steel ball(particle size 1.2-3mm)

|

|

|

Polishing time about

60 minutes

|

Polishing time about

60 minutes

|

Polishing time about

60 minutes

|

|

No burr and rag

|

|

High alumina or high frequency porcelain (particle size 4mm)

|

Zirconia or steel ball(particle size 1.2-3mm)

|

|

|

|

Polishing time about

40 minutes

|

Polishing time about

40 minutes

|

|

Refurbishment

|

|

High alumina or high frequency porcelain (particle size 4mm)

|

Zirconia or steel ball(particle size 1.2-3mm)

|

|

|

|

Polishing time about

40 minutes

|

Polishing time about

40 minutes

|

The polishing process should be referred to above, and the corresponding adjustment should be made according to the polishing process and the actual situation of the customer

Product display

You can choose your favorite color, such as white, etc.

please contact us

Packing&Shipping

Company Introduction

We introduce ourself as a leading supplier of vibrating screens, centrifugal sifters, tumbler screens, gyratory screens,spiral elevator ,screw conveyor,other types conveyor and feeding machine, and screw press with well-equipped testing equipment and strong technical force. With a wide range, high quality, reasonable prices and stylish designs, our products are extensively used in mining, pharmacy, food, chemical, metal powder and other industries.

Hot Searches