- Product Details

- {{item.text}}

Quick Details

-

Raw material:

-

oil cake /oil seed

-

Function:

-

extract oil from oil cake or oil seed

-

Capacity:

-

20-500TPD

-

Material:

-

carbon steel/stainless steel

-

Main machine:

-

rotocel extractor ,D.T.D.C toaster

-

Factory visit:

-

welcome

-

Application:

-

oil factory

-

Certification:

-

CE ISO

Quick Details

-

Place of Origin:

-

Henan, China

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Field installation, commissioning and training

-

production name:

-

soybean solvent extraction plant

-

Raw material:

-

oil cake /oil seed

-

Function:

-

extract oil from oil cake or oil seed

-

Capacity:

-

20-500TPD

-

Material:

-

carbon steel/stainless steel

-

Main machine:

-

rotocel extractor ,D.T.D.C toaster

-

Factory visit:

-

welcome

-

Application:

-

oil factory

-

Certification:

-

CE ISO

50TPD n-hexane soybean solvent extraction plant with less than 1% oil residue .

The brief introduction of solvent extraction plant

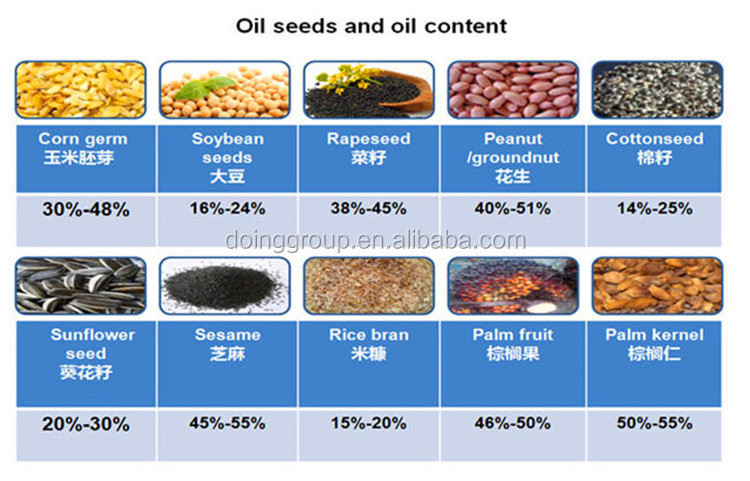

The solvent extraction plant is part of vegetable oil processing plant which is designed to extract oil directly from oil seed containing less than 20% oil like soyabean fter flaking or it extracts oils from prepressed or fully pressed cake of seeds containing more than 20% oil like sunflower, peanuts, cotton seed, palm kernel, canola, copra, castor and variety of other materials.

Function :

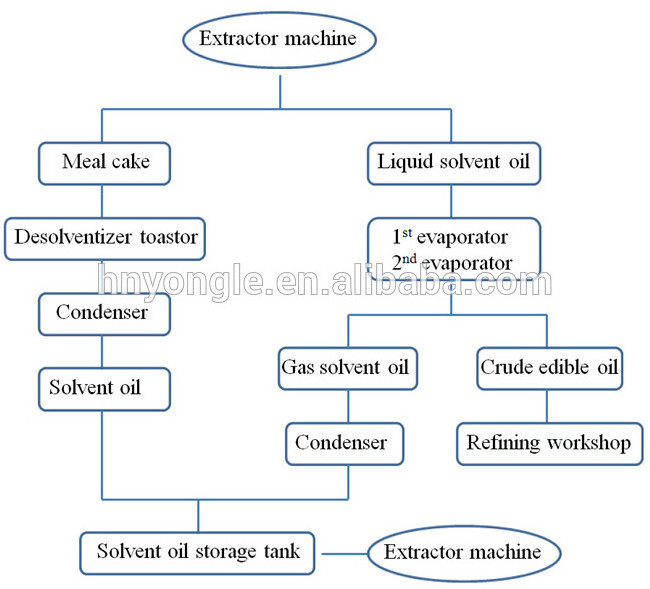

By taking advantage of oil fat and organic solvent can dissolve with each other , use the u-hexane to reach with processed oil seed or pressed oil cake to extract oil , The oil residue is less than 1% . the meal is more suitable for animal feed .

Rotocel extractor is the main equipment in oil solvent extraciton process project, Its frequency conversion can adjust the speed of cell our capacity , chain driven makes the operation stable and satety, Stainless steel fixed plates are used, Thus extractor has large surplus capacity . It is helpful to expand capacity in the future .,Meanwhile , High material level improves extraction effciency ,Extractor has 16or 18 cell, Cross grids is applied to prevent the mix oil flowing backwards into the final meal-dropping cell, Cycling solvent pumps have large flux , Low head , good sealed ,low noise ,stable

Main equipment :

(1) Solvent pumps: continuously spray solvent to the rotary-type extractor

(2).Roary extractor: Spray and soak the pre-pressed cake with solvent so that oil fats can be dissolved in solvent(form miscella). After processing, you can get wet meal and miscella (mixed oil).

(3). DTDC: usd to separate the solvent from the wet meal.

(4). Miscella tank 1st: pump the miscella (oil with solvent) in to the miscella 1st , and then add 10% saline water to it. The phospholipid and impurities in the miscella will react with the saline wter, at last the reactant precipitate, reaching the goal of purifying.

(5). Miscella tank 2nd: the purified miscella will be pumped into it.

(6). Miscella stripping: it will remove the remaining solvent in miscella. And the solvent will be discharged to condenser for recycling.

(7). condensers: used to cooling the solvent gas separated from the wet meal and miscella for recycling.