- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Package

-

Color:

-

White.eps Raw Material

-

Material:

-

EPS Foam Bead Raw Material

-

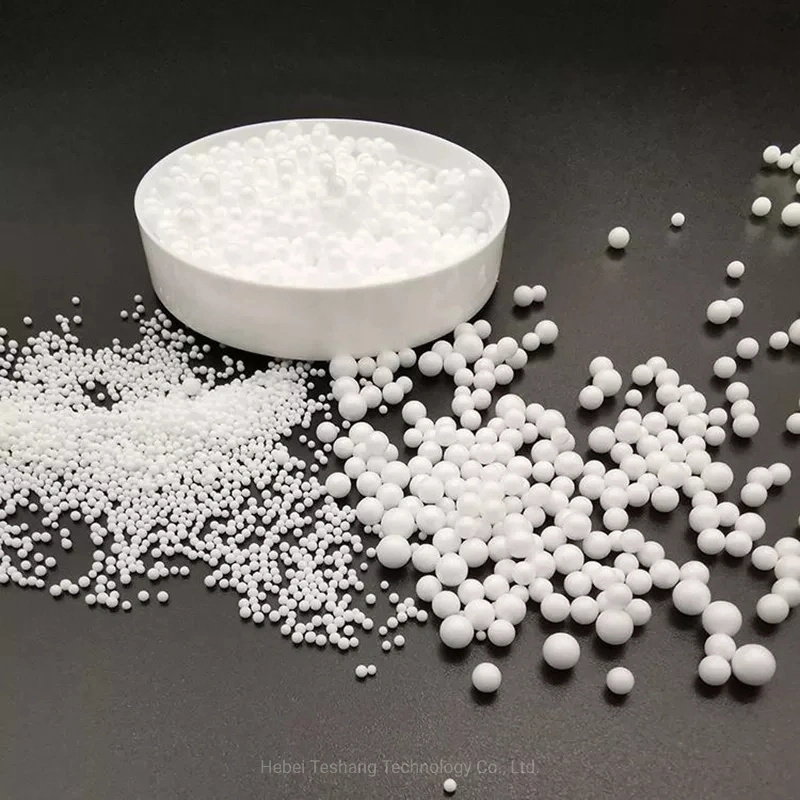

Appearance:

-

Corlorless Semi-transparent Crystalline Beads

-

Type:

-

Synthetic Resin

-

Main Component:

-

92%~96%EPS Plastic Raw Materials

-

Usage:

-

Foam Boxes Buliding Insulation

-

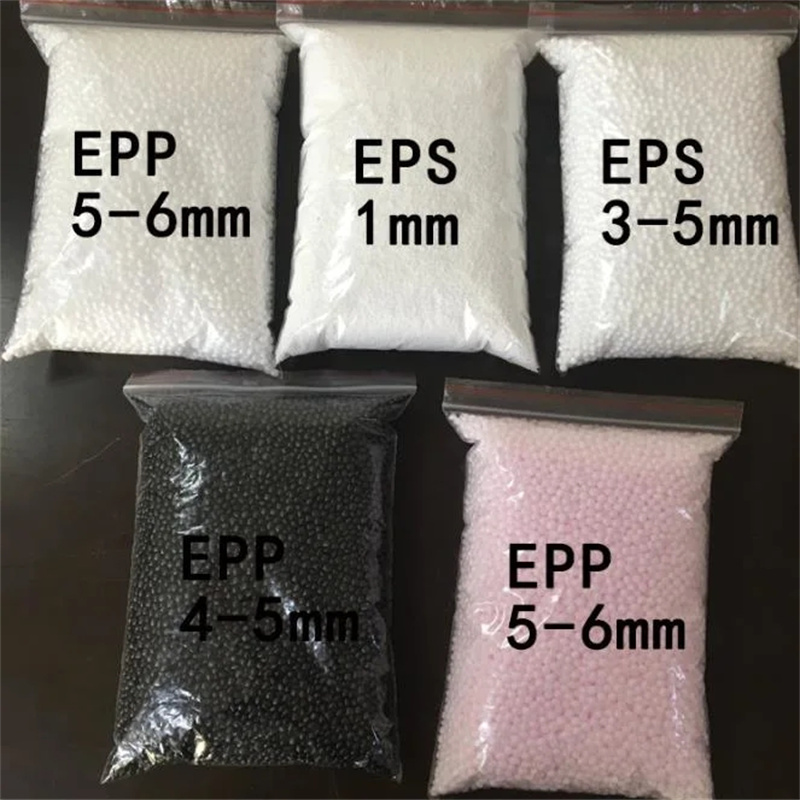

Size:

-

2-4mm

-

MOQ:

-

1 Ton

Quick Details

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

own brand

-

Product Name:

-

EPS Raw Material Expanded Polystyrene

-

Application:

-

Package

-

Color:

-

White.eps Raw Material

-

Material:

-

EPS Foam Bead Raw Material

-

Appearance:

-

Corlorless Semi-transparent Crystalline Beads

-

Type:

-

Synthetic Resin

-

Main Component:

-

92%~96%EPS Plastic Raw Materials

-

Usage:

-

Foam Boxes Buliding Insulation

-

Size:

-

2-4mm

-

MOQ:

-

1 Ton

Product Description

Expandable Polystyrene

EPS

(

Expandable Polystyrene) is a lightweight, rigid, plastic foam insulation material produced from solid particles of polystyrene. Expandsion is achieved by virtue of small amounts of pentane gas dissolved into the polystyrene base material during

production.The gas expands under the action of heat, applied as steam, to form perfectly clesed cells of EPS.

production.The gas expands under the action of heat, applied as steam, to form perfectly clesed cells of EPS.

Feature:

Good flame-retardant,

good frothing good preserving,

good binding and low heat-conducting rate.Oxygen index over 30

Good flame-retardant,

good frothing good preserving,

good binding and low heat-conducting rate.Oxygen index over 30

Specification

|

EPS Flame Retardant Material

|

|

|

|

|

|

|||||

|

Technical Data Sheet

|

|

|

|

|

|

|||||

|

Pruduct

|

EPS F-301

|

EPS F-302

|

EPS F-303

|

EPS F-401

|

EPS F-501

|

|||||

|

Density (g/L)

|

12 -14

|

14 - 16

|

15 - 18

|

18-25

|

18-25

|

|||||

|

Particle Size (mm)

|

1.00 - 1.60

|

0.85 - 1.25

|

0.70 -0.90

|

0.50 -0.80

|

0.40 - 0.60

|

|||||

|

Foaming Rate

|

75-85

|

70-80

|

0.40 - 0.60

|

60-70

|

55-65

|

|||||

|

Foaming Agent Content (%)

|

6.2 - 7.3

|

6.2 - 7.3

|

6.2 - 7.3

|

6.2 - 7.3

|

6.2 - 7.3

|

|||||

|

Styrene Residue (%)

|

≤ 2000

|

≤ 2000

|

≤ 2000

|

≤ 2000

|

≤ 2000

|

|||||

|

Moisture (%)

|

≤ 2

|

≤ 2

|

≤ 2

|

≤ 2

|

≤ 2

|

|||||

|

Moisture (%)

|

≤ 3200

|

≤ 3200

|

≤ 3200

|

≤ 3200

|

≤ 3200

|

|||||

|

Oxygen index (%)

|

≥ 30

|

≥ 30

|

≥ 30

|

≥ 30

|

≥ 30

|

|||||

|

EPS Standard Material

|

|

|

|

|

|

|||||

|

Pruduct

|

EPS E-301

|

EPS E-302

|

EPS E-303

|

EPS E-401

|

EPS E-501

|

|||||

|

Density (g/L)

|

12 -14

|

14 - 16

|

15 - 18

|

18-25

|

25 - 30

|

|||||

|

Particle Size (mm)

|

1.25 - 1.65

|

1.00 - 1.30

|

0.75 - 1.00

|

0.60 -0.80

|

0.50 - 0.70

|

|||||

|

Foaming Rate

|

80-95

|

75-85

|

70-80

|

65-75

|

60-70

|

|||||

|

Foaming Agent Content (%)

|

6.2 - 7.3

|

6.2 - 7.3

|

6.2 - 7.3

|

6.2 - 7.3

|

6.2 - 7.3

|

|||||

|

Styrene Residue (%)

|

≤ 2000

|

≤ 2000

|

≤ 2000

|

≤ 2000

|

≤ 2000

|

|||||

|

Moisture (%)

|

≤ 2

|

≤ 2

|

≤ 2

|

≤ 2

|

≤ 2

|

|||||

|

Coating (ppm)

|

≤ 3200

|

≤ 3200

|

≤ 3200

|

≤ 3200

|

≤ 3200

|

|||||

Hot Searches