- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

40GP container

-

Power (kW):

-

250 kW

-

Weight (KG):

-

25000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

fine rubber powder grinder

-

Color:

-

Blue/green or as your requirements

-

Lead time:

-

20 days

-

Brand name:

-

HVST

-

Model number:

-

xkp-350/400/450/560/560D

-

Advantage:

-

Environmental friendly, energy saving

-

Dimension:

-

40GP or 20 GP container

-

Material:

-

Waste tires

-

Shippment:

-

Marine transportation

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

HVST

-

Voltage:

-

Customer Request

-

Dimension(L*W*H):

-

40GP container

-

Power (kW):

-

250 kW

-

Weight (KG):

-

25000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

fine rubber powder grinder

-

Color:

-

Blue/green or as your requirements

-

Lead time:

-

20 days

-

Brand name:

-

HVST

-

Model number:

-

xkp-350/400/450/560/560D

-

Advantage:

-

Environmental friendly, energy saving

-

Dimension:

-

40GP or 20 GP container

-

Material:

-

Waste tires

-

Shippment:

-

Marine transportation

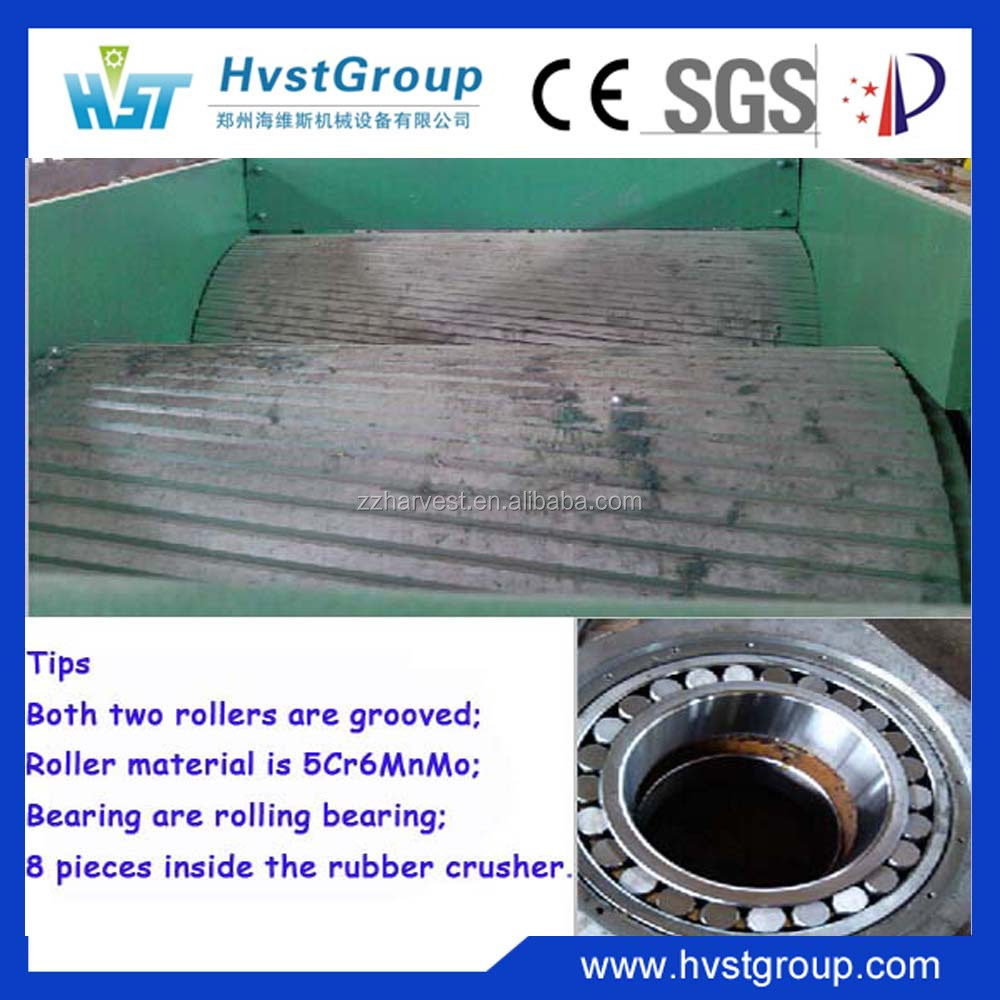

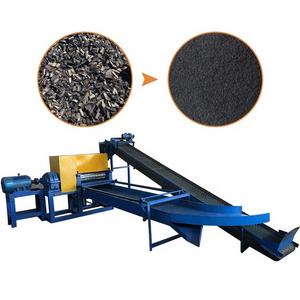

Rubber crusheris used to grind the chunks into smaller mesh powder through the vibrating screen as you need.

| Model | Drum diameter | Drum length | Roll speed ratio | Motor power |

| XKP-350 | 300mm | 500mm | 1:2.5 | 30KW |

| XKP-400 | 400mm | 600mm | 1:2.5 | 45KW |

| XKP-450 | 450mm | 760mm | 1:2.5 | 55KW |

| XKP-560 | 560mm | 800mm | 1:2.5 | 75KW |

| XKP-560D | 300mm | 1000mm | 1:2.5 | 132KW |

The working principle of the production line

Used tire shredder machine for sale/waste tire recycling rubber powder production line is to crush waste tires into rubber powder in different sizes.

The working process of waste tire recycling rubber powder production line:

Waste tire - Tire de beader- whole tire cutting - tire shredder - Rubber crushing - magnetic separator - fiber separator - Rubber powder

Q1: Are you a factory or a trading company ?

A1: We are a manufacturer with 30 years production experience in tire recycling plant and nail making machines. We have export license, we can offer you the factory prices.

Q2: Can you guarantee the capacity as you mentioned ?

A2: Definitely yes, the grooved two rollers are specially designed to increase the output and ensure the working efficient.

Q3: are you sure the final rubber powder can be completely clean out of wire steel or nylon ?

A3: The final powder purity can reach 99.9%. we have magnetic separator which can separate the wire steel from the rubber powder.