- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Shunfu

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

3600*2000*1600 or As per model

-

Weight:

-

1500 kg

-

Marketing Type:

-

Hot Product 2023

-

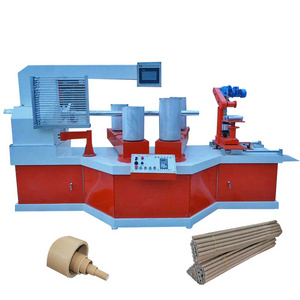

Paper tube winding machine:

-

parallel spiral paper tube rolling toilet core curling machine

-

Raw material:

-

Jumbo paper coil roll

-

Finished product:

-

Long paper tube, toilet core roll, other industry use tube

-

Wall thickness:

-

1-15mm

-

Reel speed:

-

3-16m/min

-

Winding diameter:

-

30--300mm

-

Coating method:

-

Fully automatic glue

-

Paper roll:

-

3-24 layers

-

Speed control:

-

Computer frequency conversion

-

Control way:

-

Host operation panel

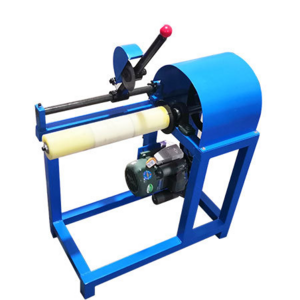

Quick Details

-

Type:

-

Paper Tube Making Machine

-

Production Capacity:

-

50 m/min

-

Max. workable width:

-

50mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Shunfu

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

3600*2000*1600 or As per model

-

Weight:

-

1500 kg

-

Marketing Type:

-

Hot Product 2023

-

Paper tube winding machine:

-

parallel spiral paper tube rolling toilet core curling machine

-

Raw material:

-

Jumbo paper coil roll

-

Finished product:

-

Long paper tube, toilet core roll, other industry use tube

-

Wall thickness:

-

1-15mm

-

Reel speed:

-

3-16m/min

-

Winding diameter:

-

30--300mm

-

Coating method:

-

Fully automatic glue

-

Paper roll:

-

3-24 layers

-

Speed control:

-

Computer frequency conversion

-

Control way:

-

Host operation panel

machine to stick paper tubes automatic parallel spiral paper tube rolling toilet core curling machine

Paper tube machine adopts paper tube in the form of drum, through electronic control operating system control, the host consist of paper frame, glue, drum, photoelectric tube cutting, and tube under a series of process, in the production of paper tube thickness, tube cutting length can be adjusted freely according to user requirement, speed is fast, simple and convenient procedure, high automation.

Features:

1. Main structure made by thicker steels which are finished by processing of re-cutting and welding, make machine much more stable and strong.

2. Main transmission adopt gear speed cut , low-noise, low-heating, high revolution, high torque.

3. Main motor adopt Vectorial high torque inverter speed adjusting.

4. Equipped with hydraulic device to adjust belt tension, with belt tension sensor and belt angle sensor, both can be adjusted automatically.

5. Equipped with synchronous cutting system, cutting table adopt high precision ball screw and high performance server motor drive.

6. Equipped with pulse length fixation control, cooperated with front feedback compensation function, can make sure the same length in different producing speed.

7. Adopt double PLC control system, IO output control and functional operation control separately, to increase cutting reaction speed, cutting length is much more accurate.

8. Equipped with new control panel and big size colorful main machine touching interface .

9. with multi functional bottom paper feeding device, will stop once paper break.

10. Equipped with integral paper reel stand, glue stand, paper feeding assembly, all are electrical control.

11. Design of modularization electric layout makes use,maintaining and repairing more convenient and scientific.

12. Network module can be optional ,used for network connection work with many equipment and assembly line, also might be used to remote monitoring and maintaining, MODBUS TCP agreement.

Technical Data Sheet:

Use:

All kinds of toilet paper roll, film winding ,paper winding ,all kinds of middle sized industrial paper core. Chemical fiber paper tube ,all kinds of composite paper can , all kinds of small industrial paper core

As a professional manufacturer and exporter of paper tube machine in China over 35 years, we have established long term biz relationship with more than 30 countries and regions, such as Europe, Middle East, Africa, Asia, South Ameria etc. Tha above picture just a little case for your reference. For more information, welcome to contact us freely!