- Product Details

- {{item.text}}

Quick Details

-

Production Capacity:

-

11m/s

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

JZSK

-

Voltage:

-

380V/220V

-

Dimension(L*W*H):

-

1660x1330x1700

-

Weight:

-

1400 kg

-

Core Components:

-

abrasive wire

-

Name:

-

CNC Abrasive Wire Cutting Machine for Jade Carving Gemstone Cutting

-

Machine TYPE:

-

Abrasive Wire Cutting Machine

-

Worktable Size:

-

380*600mm

-

Worktable Travel:

-

400*320mm

-

Max.Workpiece Thickness:

-

400mm

-

Max.load Weight:

-

300kg

-

Working Speed:

-

11m/s

-

Working Liquid:

-

Pure water or tap water, emulsifying water (According to the material)

-

Tension control:

-

Precision pneumatic control

-

Application:

-

graphite, jade, ceramics, etc.

Quick Details

-

Type:

-

Stone Cutting Machine

-

Power:

-

3000

-

Cutting thickness (max):

-

400mm

-

Production Capacity:

-

11m/s

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

JZSK

-

Voltage:

-

380V/220V

-

Dimension(L*W*H):

-

1660x1330x1700

-

Weight:

-

1400 kg

-

Core Components:

-

abrasive wire

-

Name:

-

CNC Abrasive Wire Cutting Machine for Jade Carving Gemstone Cutting

-

Machine TYPE:

-

Abrasive Wire Cutting Machine

-

Worktable Size:

-

380*600mm

-

Worktable Travel:

-

400*320mm

-

Max.Workpiece Thickness:

-

400mm

-

Max.load Weight:

-

300kg

-

Working Speed:

-

11m/s

-

Working Liquid:

-

Pure water or tap water, emulsifying water (According to the material)

-

Tension control:

-

Precision pneumatic control

-

Application:

-

graphite, jade, ceramics, etc.

Products Description

Reciprocating numerical control abrasive wire cutting machine

1. This machine is widely used for cutting and forming semi-conductive and non-conductive materials such as graphite, jade, glass and ceramics.The machine is convenient to operate, occupies a small area and is convenient to transport.

2. In the jade and jadeite industry, this machine is especially widely used. When cutting jade materials, the loss is small, the cost is saved, and the forming quality of jade jadeite is improved.

3. The machine can be equipped with taper function, which has outstanding performance for the processing of upper and lower abnormity workpieces.

Main Technical Data

2. In the jade and jadeite industry, this machine is especially widely used. When cutting jade materials, the loss is small, the cost is saved, and the forming quality of jade jadeite is improved.

3. The machine can be equipped with taper function, which has outstanding performance for the processing of upper and lower abnormity workpieces.

Main Technical Data

|

Model

|

SX7720

|

SX7725

|

SX7732

|

SX7740

|

SX7750

|

SX63

|

|||||

|

Worktable size(mm)

|

270x420

|

340x520

|

380x600

|

410x710

|

596x880

|

720x1260

|

|||||

|

X axis travel(mm)

|

250

|

320

|

400

|

500

|

650

|

1000

|

|||||

|

Y axis travel(mm)

|

200

|

200

|

320

|

400

|

550

|

630

|

|||||

|

Max.load weight(kg)

|

100

|

200

|

300

|

400

|

500

|

750

|

|||||

|

Max.Workpiece Thickness(mm)

|

200

|

300

|

400

|

500

|

600

|

600

|

|||||

|

Stroke of

taper device

(optional) (mm)

|

30x30

|

|

|

|

|

|

|||||

|

Maximum taper

(optional)

|

±1.5° /80

|

|

|

|

|

|

|||||

|

Max.diameter

of rotating fixture

(optional) (mm)

|

200

|

300

|

400

|

500

|

600

|

600

|

|||||

|

Max.load of

Rotating Fixture

(Optional)

|

30

|

50

|

50

|

100

|

150

|

150

|

|||||

|

Dia of abrasive wire

(mm)

|

0.33-0.45

|

|

|

|

|

|

|||||

|

Working speed

(m/s)

|

11

|

|

|

|

|

|

|||||

|

Length(m)

|

≤200

|

≤200

|

≤300

|

≤300

|

≤400

|

≤400

|

|||||

|

Cutting material

|

Non-conductive materials such as graphite, jade, ceramics, etc

|

|

|

|

|

|

|||||

|

Working Liquid

|

Pure water or tap water, emulsifying water (According to the material)

|

|

|

|

|

|

|||||

|

Tension control

|

Precision pneumatic control

|

|

|

|

|

|

|||||

|

Total power of

machine (kw)

|

≤3

|

|

|

|

|

|

|||||

|

Machine dimension

(mm)

|

1300x1100

x1700

|

1485x1050

x1700

|

1660x1330

x1700

|

1830x1490

x1800

|

2010x1800

x1900

|

2200x2200

x1900

|

|||||

|

Machine weight(kg)

|

500

|

1200

|

1400

|

1600

|

2000

|

3000

|

|||||

|

Homepage

|

|

Price

|

|

|

|||||||

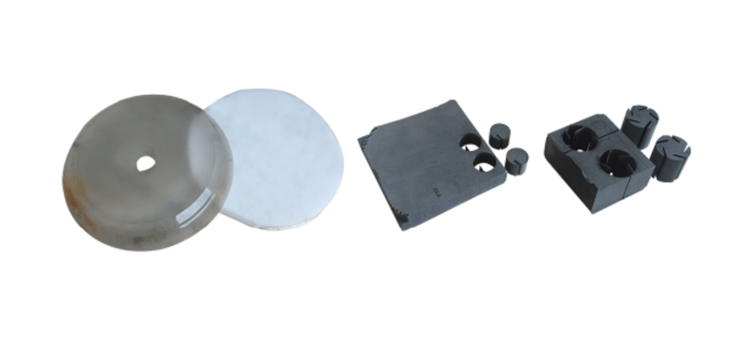

Product Display

Workpiece Show

Warranty period: one year

During warranty period, if you have any parts broken because of qulity problem, we will supply to you free of charge by express.

Out of warranty period, if you have any question, you can contact with us, we will supply our best service to you as usual.

1.Technical support online service provided .

2.Technical files service provided.

3.Machine operation video provided

4.On-site training service provided.

5.Spare parts replacement and repair service provided.

6.All of the questions will be replied within 24 hours

During warranty period, if you have any parts broken because of qulity problem, we will supply to you free of charge by express.

Out of warranty period, if you have any question, you can contact with us, we will supply our best service to you as usual.

1.Technical support online service provided .

2.Technical files service provided.

3.Machine operation video provided

4.On-site training service provided.

5.Spare parts replacement and repair service provided.

6.All of the questions will be replied within 24 hours

Main Products

Hot Searches