- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

2500*1000*1450mm

-

Power (kW):

-

11 kW

-

Weight (KG):

-

200 KG

-

Product name:

-

Open rubber mixing machine

-

Application:

-

Widely

-

Color:

-

Customer Required

-

Power supply:

-

220V 50Hz

-

Model:

-

Coustomization

-

MOQ:

-

1 Set

-

Brand:

-

Hong Jin

-

Port:

-

Shen Zhen

-

Delivery time:

-

7-15days

-

Size:

-

Custom Size

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

HJ

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

2500*1000*1450mm

-

Power (kW):

-

11 kW

-

Weight (KG):

-

200 KG

-

Product name:

-

Open rubber mixing machine

-

Application:

-

Widely

-

Color:

-

Customer Required

-

Power supply:

-

220V 50Hz

-

Model:

-

Coustomization

-

MOQ:

-

1 Set

-

Brand:

-

Hong Jin

-

Port:

-

Shen Zhen

-

Delivery time:

-

7-15days

-

Size:

-

Custom Size

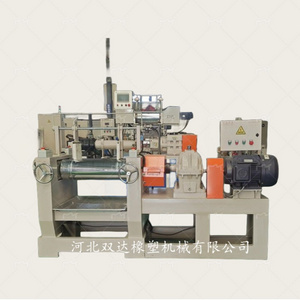

Product Paramenters

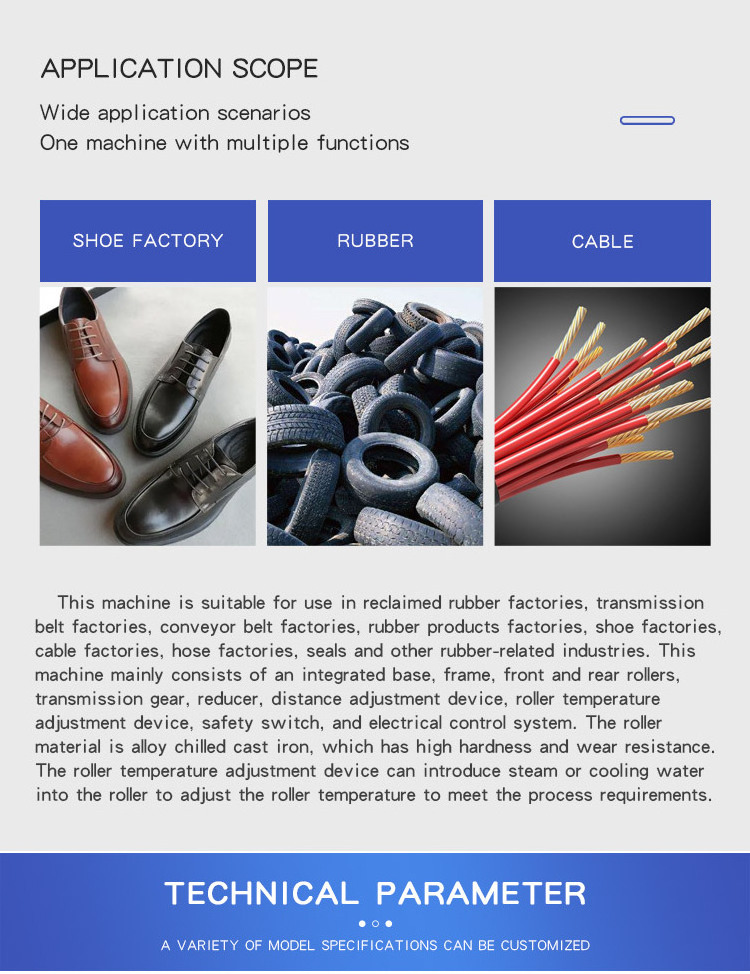

Scope of application

This machine is suitable for use in reclaimed rubber factories, transmission belt factories, conveyor belt factories, rubber products factories, shoe factories, cable factories, hose factories, seals and other rubber-related industries. This machine mainly consists of an integrated base, frame, front and rear rollers, transmission gear, reducer, distance adjustment device, roller temperature adjustment device, safety switch, and electrical control system. The roller material is alloy chilled cast iron, which has high hardness and wear resistance. The roller temperature adjustment device can introduce steam or cooling water into the roller to adjust the roller temperature to meet the process requirements.

Structure introduction:

1. This machine is mainly composed of an integrated base, frame, roller, transmission gear, gear reduction, motor and other components. The roller is made of chilled cast iron. The surface of the workpiece is ground and has high hardness and wear resistance. The inside of the roller is hollow and filled with water and drainage system. The machine has a desktop structure. The worm gear reducer is installed next to the machine base, and the rollers and frame are placed on the upper part of the machine, making it compact and easy to operate.

2. The transmission part of the machine is driven by a hard-tooth surface reducer motor located outside the machine base. The rear roller is driven to rotate through the transmission gear, and then the front roller is driven by a pair of speed ratio gears installed at the left end of the roller to make the front and rear rollers rotate. The support rollers rotate in opposite directions at different speeds.

3. The transmission gears are all equipped with closed protection devices, and the machine is equipped with an electrical braking device. When an emergency stop is needed, press the emergency stop switch to brake immediately, making the safety performance more reliable. This machine is designed and manufactured by our company. It is mainly used for mixing equipment of silicone and rubber. It has the characteristics of exquisite structure, safety and convenience, wide applicability and high efficiency.

Equipment advantages:

1. Easy to carry: The bottom space is designed to facilitate forklift transportation.

2. Integrated numerical control: The power switch and stop switch are integrated together for easy use.

3. Safety devices: multiple touch-type emergency stops, as well as hand-operated safety levers. The designed touch-type emergency stop reversal lever can be touched to reverse immediately in order to prevent employees from being accidentally brought in by the stick during work. .

4. Chrome-plated cylinder: The silver cylinder is made of high-strength stainless steel, which has been quenched, cylindrically ground, hard chromium electroplated, cylindrically ground, and mirror polished to make it less likely to stick to materials, delaminate, deform, and rust.

5. Install a rotary joint to circulate cold water and achieve good cooling effect.

6. Stainless steel tray, not easy to rust and easy to clean.

|

Equipment model:

|

|

HJ-230

|

|

Roller diameter:

|

|

230mm/9in

|

|

||||||

|

|

|

|

|

|

|

|

|

||||||

|

Roll surface width:

|

|

700mm

|

|

Roller spacing:

|

|

1mm-12mm

|

|

||||||

|

|

|

|

|

|

|

|

|

||||||

|

Spacing display:

|

|

Mechanical dial

|

|

Roller speed ratio:

|

|

1;1.25

|

|

||||||

|

|

|

|

|

|

|

|

|

||||||

|

Safety device:

|

|

Contact emergency stopper

|

|

Number of safety devices:

|

|

multiple

|

|

||||||

|

|

|

|

|

|

|

|

|

||||||

|

Front roller line speed:

|

|

13r/min

|

|

Mixing capacity:

|

|

15-20kg

|

|

||||||

|

|

|

|

|

|

|

|

|

||||||

|

Receiving device:

|

|

SUS304 stainless steel tray

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

||||||

|

Special Features:

|

|

Emergency stop with brake reversal function

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

||||||

|

Roll temperature:

|

|

Water cooling/electric heating (either one is quoted)

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

||||||

|

Roller temperature control routine:

|

|

1.5℃-3.5℃/ room temperature -200℃

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

||||||

|

Temperature controller:

|

|

Intelligent digital display

|

|

Motor power:

|

|

11KW

|

|

||||||

|

|

|

|

|

|

|

|

|

||||||

|

Bearing situation:

|

|

Double front plain bearings

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

||||||

|

Reducer box:

|

|

Hard gear face precision reducer

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

||||||

|

Power supply voltage:

|

|

3$AC380V 40A

|

|

Machine weight:

|

|

≈2000-2500kg

|

|

||||||

|

|

|

|

|

|

|

|

|

||||||

|

Machine size:

|

|

≈2500*1000*1450mm

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

||||||

Products Description

Hot Searches