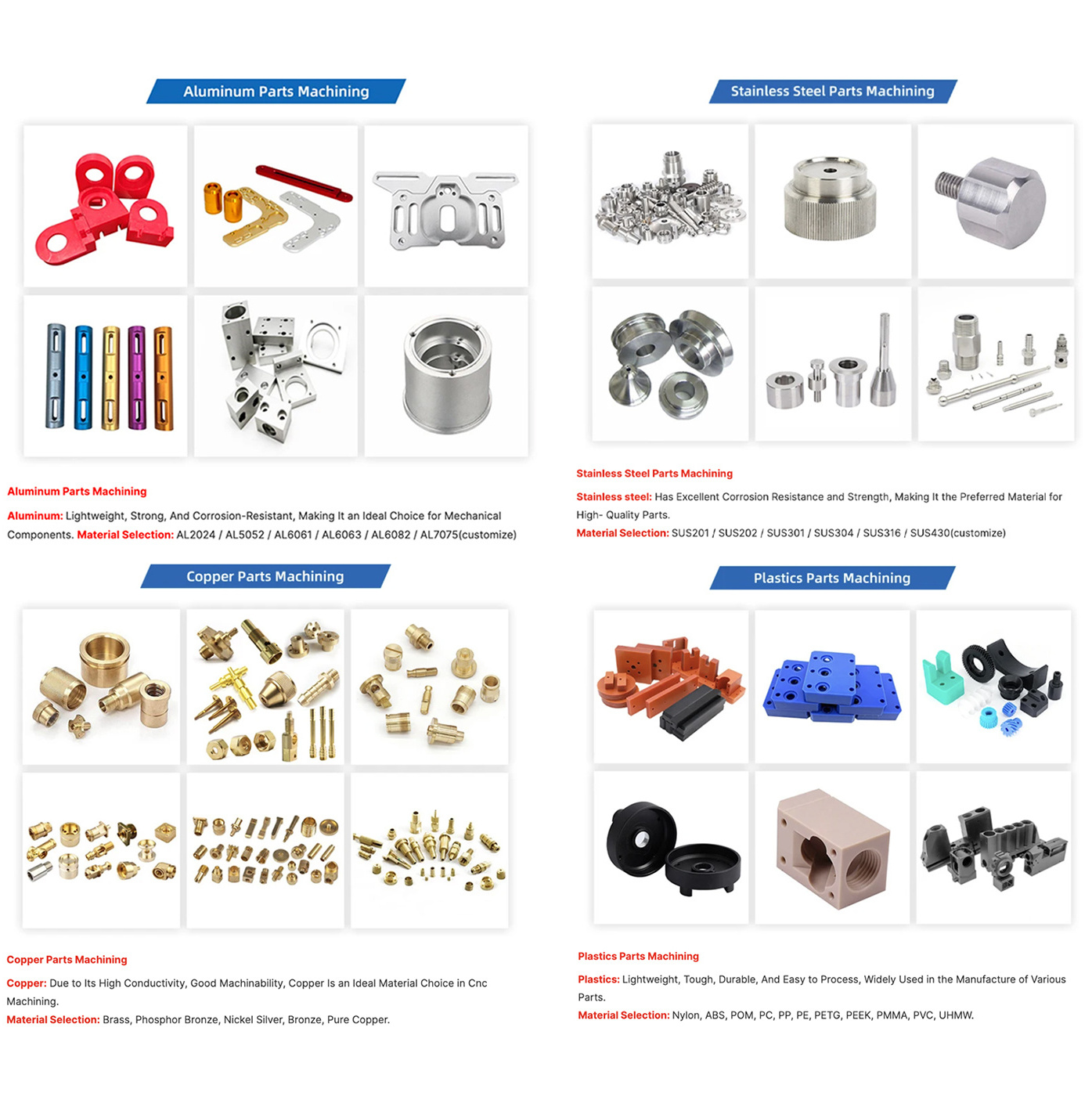

Aluminum:

Lightweight, Strong, And Corrosion-Resistant, Making It an Ideal Choice for Mechanical Components.

Material Selection:

AL2024 / AL5052 / AL6061 / AL6063 / AL6082 / AL7075(customize)

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

custom

-

Brand Name:

-

oem, Pusher

-

Product name:

-

Precision CNC Milling Service

-

Materials Avaliable:

-

aluminium/Stainless steel/brass/plastic

-

Application:

-

optical/automobile/medical/Printer device

-

Surface treatment:

-

sand blasting/black anodizing/Polished

-

Processing Type:

-

CNC machining turning milling

Quick Details

-

CNC Machining or Not:

-

Cnc Machining

-

Material Capabilities:

-

Aluminum, Brass, Copper, Hardened Metals, Precious Metals, Stainless steel

-

Place of Origin:

-

Guangdong, China, Guangdong, China

-

Model Number:

-

custom

-

Brand Name:

-

oem, Pusher

-

Product name:

-

Precision CNC Milling Service

-

Materials Avaliable:

-

aluminium/Stainless steel/brass/plastic

-

Application:

-

optical/automobile/medical/Printer device

-

Surface treatment:

-

sand blasting/black anodizing/Polished

-

Processing Type:

-

CNC machining turning milling

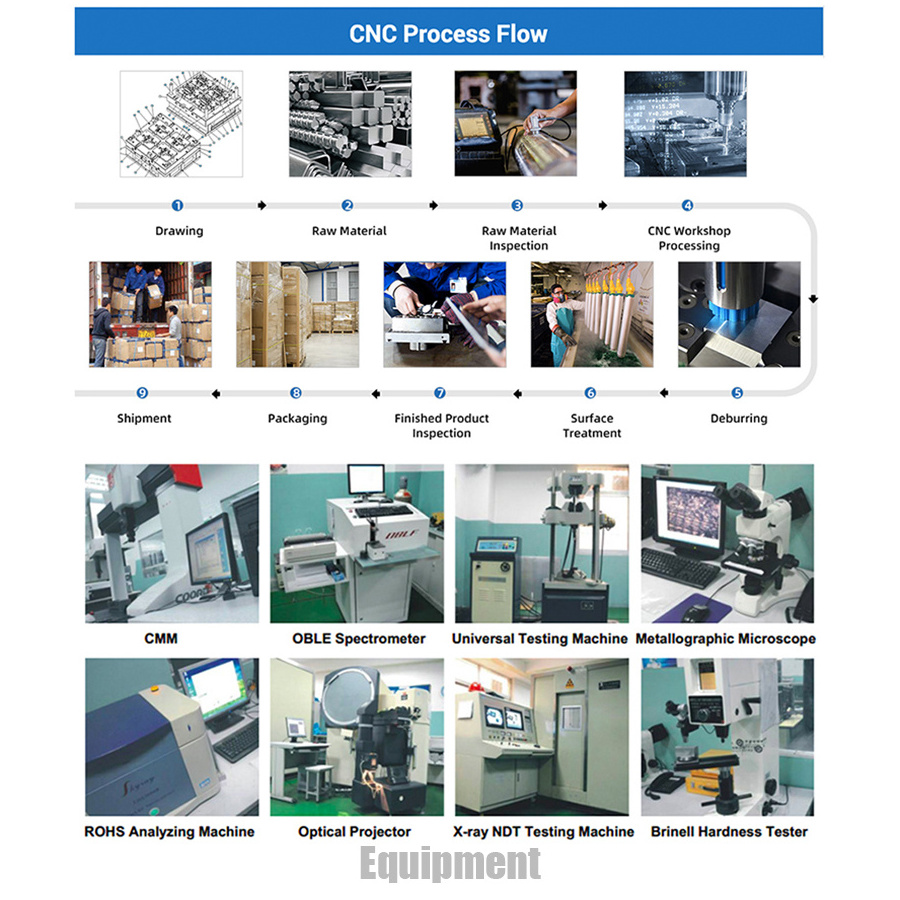

OUR SERVICES

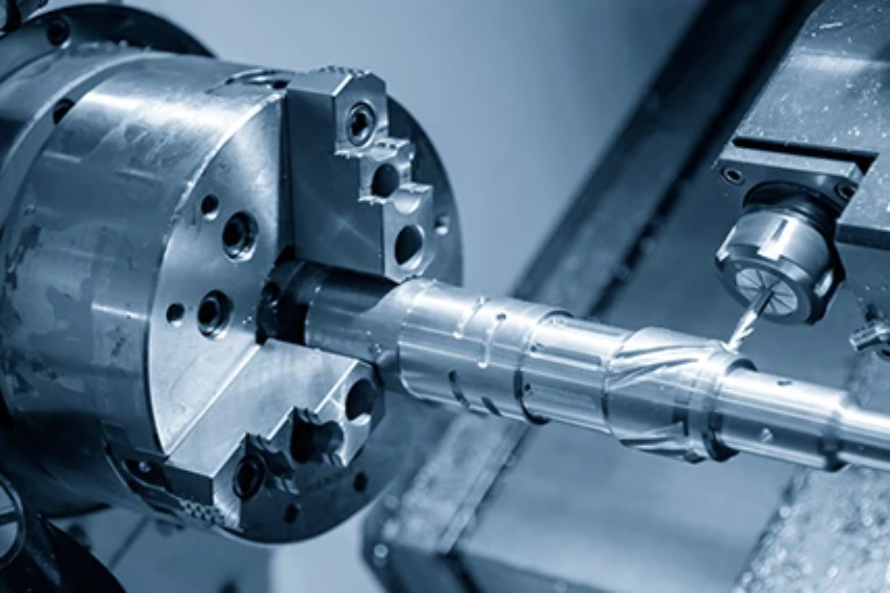

CNC Turning Processing

OEM&ODM

Customized Precision Parts 1-piece minimum order

24-hour quotation

Samples: 1-3 Days

Lead time: 7-14 Days

QC team, inspection

Report Guarantee:

Lifetime After-Sales Service

Customized Precision Parts 1-piece minimum order

24-hour quotation

Samples: 1-3 Days

Lead time: 7-14 Days

QC team, inspection

Report Guarantee:

Lifetime After-Sales Service

CNC Milling Processing

OEM&ODM

Our CNC milling services can produce highly accurate and complex parts from a variety of materials, including

metals, plastics,and composites.

Machinery Axis: 3,4,5,6

Tolerance: +/- 0.01-0.05mm

Special Areas : +/-0.002mm

Supply Ability: 500000Piece/Month

Metal fabrication

1. Production machine: laser cutting machine, punching machine, bending machine

2. Tolerance:

+/-0.01mm

Surface Finishing

We provides real production-level surface finishing for rapid prototyping & production, such as

painting, powder coat,anodized, and chromed finishes.

Manufacturing Process CNC Machining

Machining Equipments

DAHLIH Horizontal Machine Center

Machine Travel:1350×1000×1000mm

Machine Travel:1350×1000×1000mm

Quantity:5sets

HAAS Horizontal Machine Center

Machine Travel:1626×1016×813mm

Machine Travel:1626×1016×813mm

Quantity:8sets

MAKINO Horizontal Machine Center

Machine Travel:810×730×800mm

Machine Travel:810×730×800mm

Quantity:10sets

OKUMA Horizontal Machine Center

Machine Travel: 1000×800×810mm

Machine Travel: 1000×800×810mm

Quantity:6sets

Horizontal NC Lathe

The Max. Machine Travel: ∮ 630mm×1000mm

Quantity:13sets

Vertical Machine Center

The Max. Machine Travel:1626×813×762mm

Quantity:12sets

Quality Inspection

Roughness Tester

Roughness Tester

Handheld hardness tester

Surface Treatment

CNC Machined Parts Surface Treatment.

(1) Physical surface treatment:

sandblasting, wire drawing, shot blasting, polishing, rolling, polishing, brushing, spraying,

painting, powder spraying, silk screen printing, pad printing, water transfer printing, electrophoresis, etc.

painting, powder spraying, silk screen printing, pad printing, water transfer printing, electrophoresis, etc.

(2) Chemical surface treatment:

bluish blackening, phosphating, pickling, electroless plating, TD treatment, QPQ treatment, carburizing, nitriding, chemical oxidation, passivation, etc.

(

3) Electrochemical surface treatment:

anodic oxidation, hard anodic oxidation, electrolytic polishing, electroplating, etc.

(4) Modern surface treatment:

chemical vapor deposition CVD, physical vapor deposition PVD, ion implantation, ion plating, laser surface treatment, etc.

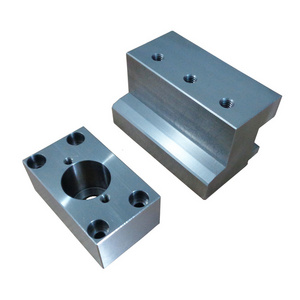

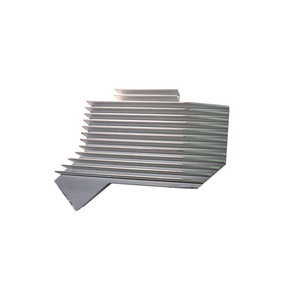

Product Display

Aluminum Parts Machining

Stainless Steel Parts Machining

Stainless steel:

Has Excellent Corrosion Resistance and Strength, Making It the Preferred Material for High- Quality Parts.

Material Selection:

SUS201 / SUS202 / SUS301 / SUS304 / SUS316 / SUS430(customize)

Copper Parts Machining

Copper:

Due to Its High Conductivity, Good Machinability, Copper Is an Ideal Material Choice in Cnc Machining.

Material Selection:

Brass, Phosphor Bronze, Nickel Silver, Bronze, Pure Copper.

Plastics Parts Machining

Plastics:

Lightweight, Tough, Durable, And Easy to Process, Widely Used in the Manufacture of Various Parts.

Material Selection:

Nylon, ABS, POM, PC, PP, PE, PETG, PEEK, PMMA, PVC, UHMW.

|

Material

|

1) Aluminum: AL 6061-T6, 6063, 7075-T etc.

|

|

|

2) Stainless steel: 303,304,316L, 17-4(SUS630) etc.

|

|

|

3) Steel: 4140, Q235, Q345B,20#,45# etc.

|

|

|

4) Titanium: TA1,TA2/GR2, TA4/GR5, TC4, TC18 etc.

|

|

|

5) Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc.

|

|

|

6) Copper, bronze, Magnesium alloy, Delrin, POM,Acrylic, PC, etc.

|

|

Finish

|

Sandblasting, Anodize color, Blackenning, Zinc/Nickl Plating, Polish.

|

|

|

Power coating, Passivation PVD, Titanium Plating, Electrogalvanizing.

|

|

|

Electroplating chromium, electrophoresis, QPQ(Quench-Polish-Quench).

|

|

|

Electro Polishing,Chrome Plating, Knurl, Laser etch Logo, etc.

|

|

Main Equipment

|

CNC Machining center(Milling), CNC Lathe, Grinding machine.

|

|

|

Cylindrical grinder machine, Drilling machine, Laser Cutting Machine,etc.

|

|

Drawing format

|

STEP,STP,GIS,CAD,PDF,DWG,DXF etc or samples.

|

|

Tolerance

|

+/-0.01mm ~ +/-0.05mm

|

|

Surface roughness

|

Ra 0.1~3.2

|

|

Inspection

|

Complete inspection lab with Micrometer, Optical Comparator, Caliper Vernier,CMM.

|

|

|

Depth Caliper Vernier, Universal Protractor, Clock Gauge, Internal Centigrade Gauge.

|

|

Capacity

|

CNC turning work range: φ0.5mm-φ150mm*300mm.

|

|

|

CNC milling work range: 510mm*1020mm*500mm.

|

Hot Searches