- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

OEM

-

Weight:

-

2500 KG

-

Place of Origin:

-

Shanghai, China

-

Voltage:

-

380V

-

Power:

-

3.75KW

-

Product name:

-

Tomato Paste Filling Production Line

-

Application:

-

Food Processing Machine

-

After-sales Service Provided:

-

Video Technical Support

-

Name:

-

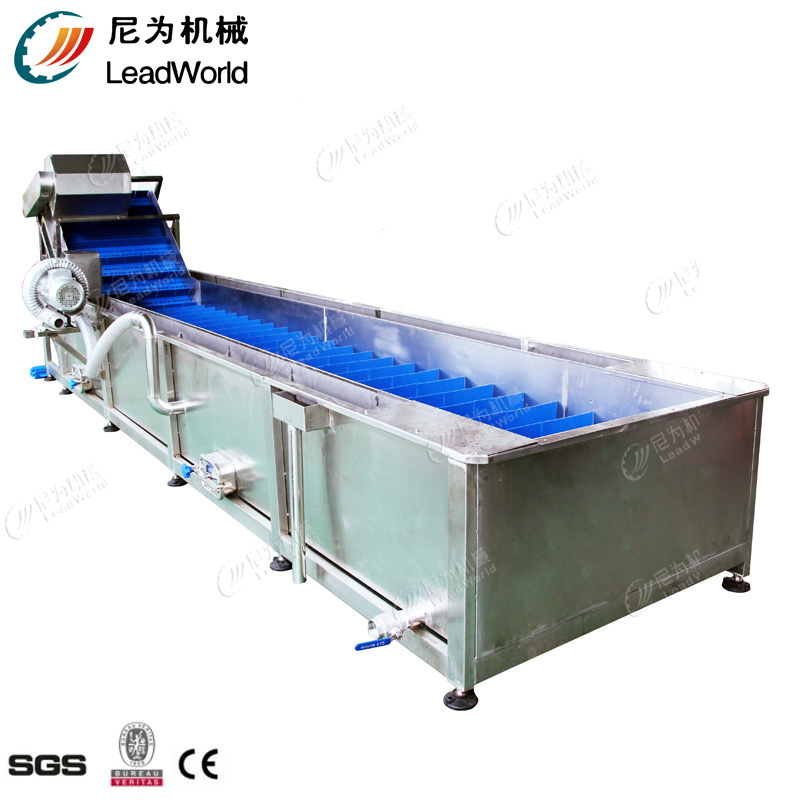

Vegetable Processing Machine

-

Type:

-

Fully Automatic

-

Function:

-

Multifunctional

-

Usage:

-

Food Industry Equipment

-

Keywords:

-

Easy Operate High Productivity

-

Final product:

-

Tomato Ketchup

-

Feature:

-

High Efficiency Easy Operate

Quick Details

-

Machinery Capacity:

-

OEM

-

Brand Name:

-

Leadworld

-

Year:

-

OEM

-

Dimension(L*W*H):

-

OEM

-

Weight:

-

2500 KG

-

Place of Origin:

-

Shanghai, China

-

Voltage:

-

380V

-

Power:

-

3.75KW

-

Product name:

-

Tomato Paste Filling Production Line

-

Application:

-

Food Processing Machine

-

After-sales Service Provided:

-

Video Technical Support

-

Name:

-

Vegetable Processing Machine

-

Type:

-

Fully Automatic

-

Function:

-

Multifunctional

-

Usage:

-

Food Industry Equipment

-

Keywords:

-

Easy Operate High Productivity

-

Final product:

-

Tomato Ketchup

-

Feature:

-

High Efficiency Easy Operate

Product Description

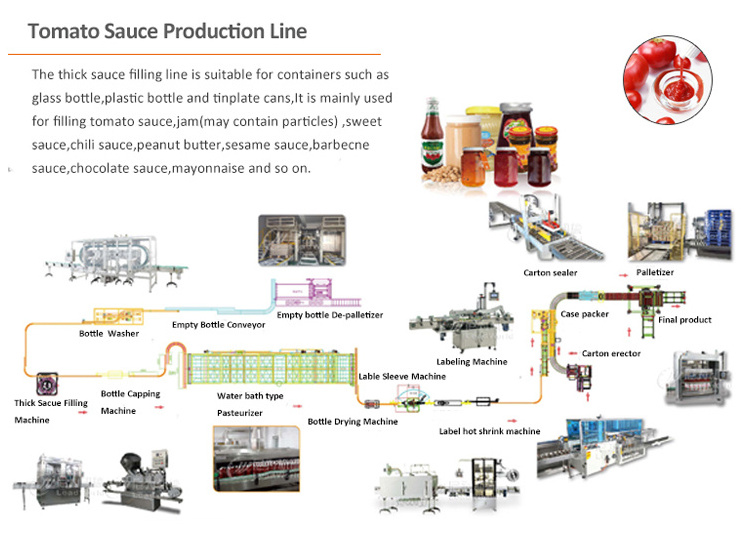

Tomato Paste Filling Production Line

1.tomato (fruit or vegetable) → 2.Digging nuclear →3.Turnover→4.Soda water spraying→5.Peeler and cleaner → 6.pre-cooked → 7.cooling → 8.pick → 9.go hair→10.Slicer →11.Filling(←Botte washing←Depalletizer)→12.Pouring juice→13.Exhauster→14.Sealing→15.Canned tomato→16.Sterilization→17.Dryer→18.Cans Palletizer

→

19.Warehousing→20.Labeler→21.Finished product→22.Case packer→23.Case Palletizer→24.Shipments

Filling Machine Parameters:

|

Product Name

|

Tomato Paste Production Line Making Machine Tomato Paste Process Line

|

|

|

|

|

||||

|

Model

|

Filling Volume

|

Air Pressure

|

Filling Accuracy

|

Total Power

|

Machine Size(mm)

|

||||

|

LW--4A

|

10-60g

30-100g

100-500g

200-1000g

500-2500ml

1000-5000ml

|

120L/min

|

Liquid≤±0.5%

Paste≤±1

|

3P 380V 50/60HZ 1.369KW

|

L2200*W1020*H2250

|

||||

|

LW--6A

|

|

140L/min

|

Liquid≤±0.5%

Paste≤±1

|

3P 380V 50/60HZ 1.69KW

|

L2500*W1020*H2250

|

||||

|

LW--8A

|

|

160L/min

|

Liquid≤±0.5%

Paste≤±1

|

3P 380V 50/60HZ 2.07KW

|

L2500*W1020*H2250

|

||||

|

LW--10A

|

|

180L/min

|

Liquid≤±0.5%

Paste≤±1

|

3P 380V 50/60HZ 2.82KW

|

L3000*W1020*H2250

|

||||

|

LW--12A

|

|

300L/min

|

Liquid≤±0.5%

Paste≤±1

|

3P 380V 50/60HZ 2.82KW

|

L3000*W1020*H2250

|

||||

Features:

1. Vacuum Preventing Leaking System

2. No Bottle or Lack of Bottle, No Filling System

3. Photoelectric Sensor, Mechatronics Filling Adjustment System

4. Photoelectric Sensor, Material Level Control Feeding System

5. Stainless Steel Frame,Plexiglass as Security Cover

6. Control System: PLC/Electronic-Pneumatic Controlled

7. Operation Panel: "Intelligent" Colorful Touch Screen

8. Filling Accuracy:+-5%

9. Capacity Adjustment:All cylinders adjusted automatically combine single cylinder adjusted individually.

10.Container transport:Stainless steel frame and engineering plastic plate chain variable speed conveyor, with photoelectric

sensor

2. No Bottle or Lack of Bottle, No Filling System

3. Photoelectric Sensor, Mechatronics Filling Adjustment System

4. Photoelectric Sensor, Material Level Control Feeding System

5. Stainless Steel Frame,Plexiglass as Security Cover

6. Control System: PLC/Electronic-Pneumatic Controlled

7. Operation Panel: "Intelligent" Colorful Touch Screen

8. Filling Accuracy:+-5%

9. Capacity Adjustment:All cylinders adjusted automatically combine single cylinder adjusted individually.

10.Container transport:Stainless steel frame and engineering plastic plate chain variable speed conveyor, with photoelectric

sensor

Product Show

Hot Searches