a modern enterprise which combine the ability of design, development, manufacturing, engineering, installation, technical services, has special technology to design and exploit by CAD software and computer and is a outstanding leader among valve fields.

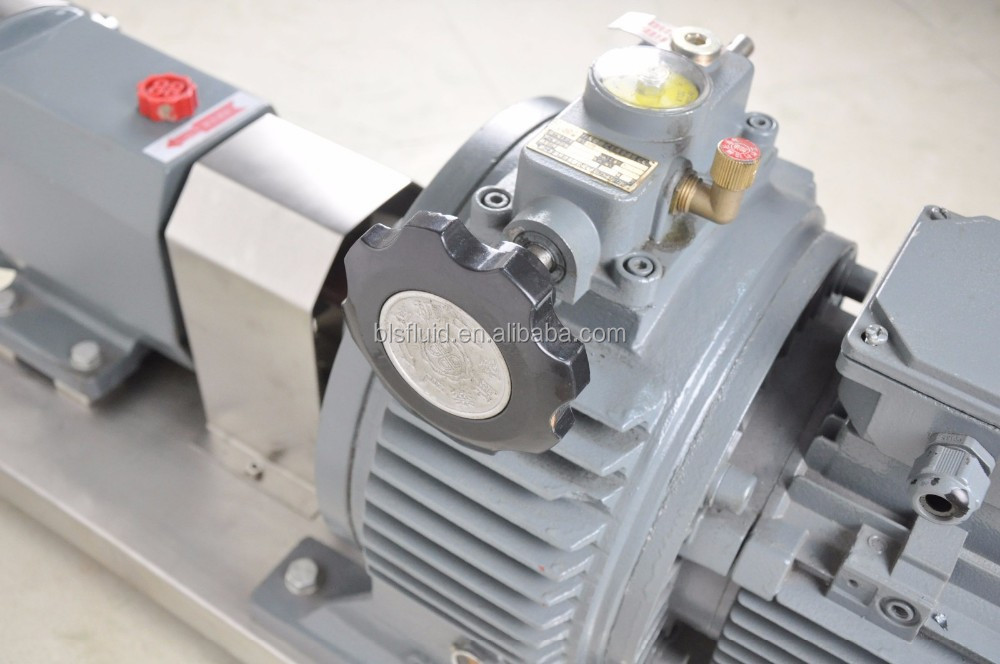

We have advanced CNC lathes imported from Japan.We can manufacture the valves and fitting according to ISO, DIN, IDF, SMS, 3A, while we can produce the products per as the requirement from the clients(non-standard).

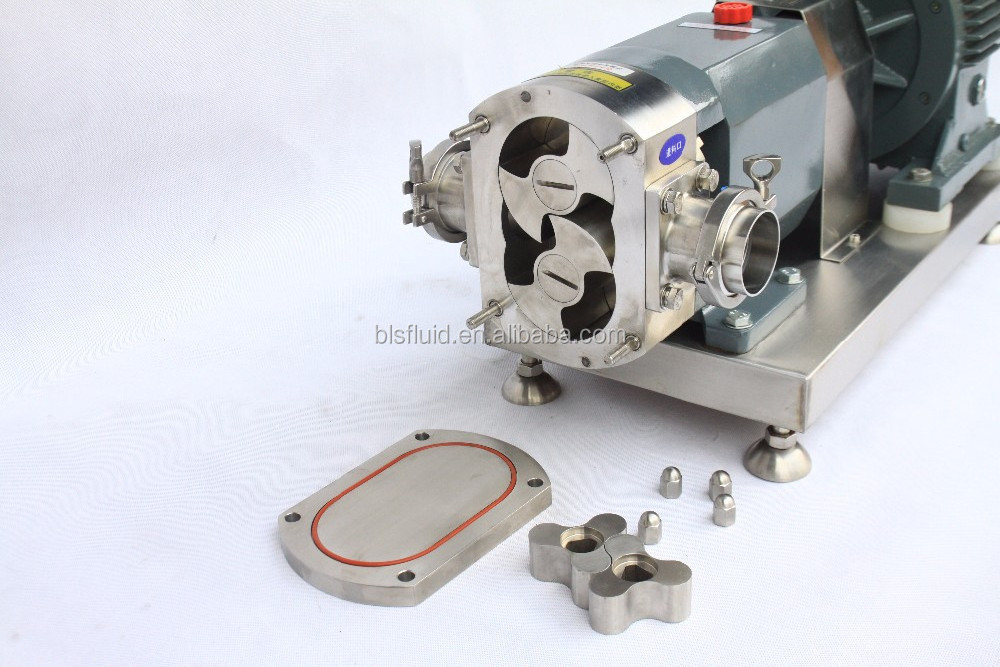

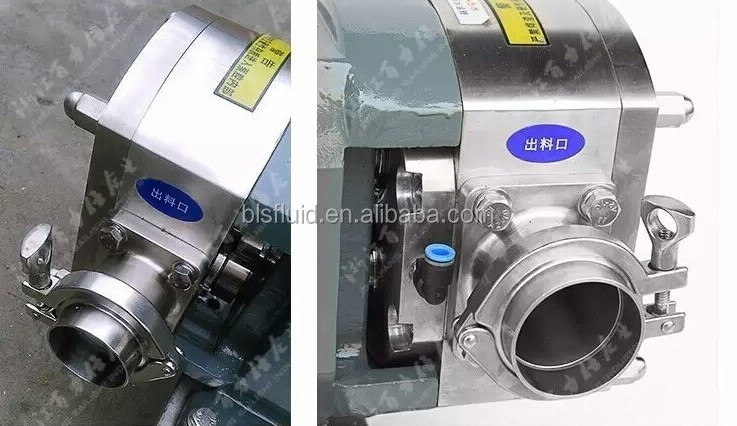

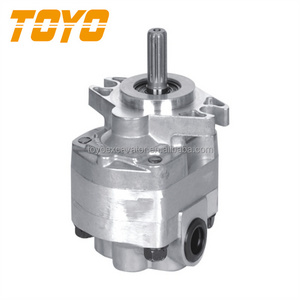

We are specialized in producing different kinds of valves, pipe fitting, tubes, manhole covers, pumps, tanks etc for many years. We can design the products according to your special request. OEM is welcome too.