- Product Details

- {{item.text}}

Quick Details

-

Screw Speed (rpm):

-

50 rpm

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

LITAI MACHINERY

-

Voltage:

-

custom made

-

Dimension(L*W*H):

-

L12000xW2400xH1800mm

-

Power (kW):

-

270

-

Weight:

-

8000 KG

-

Flow channel type:

-

hanger type

-

Die head valid width:

-

950mm

-

screen changer:

-

hydraulic

-

Heating Way:

-

Aluminum-casted heater

-

water pressure:

-

2KG

-

Air Source:

-

0.3m³/hr

-

Barrel heating power:

-

48KW

-

Barrel heating material:

-

38CRMOAIA

-

Barrel cooling method:

-

air cooling

-

Hopper Capacity:

-

120KGS

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

32:1

-

Screw diameter (mm):

-

110

-

Screw Speed (rpm):

-

50 rpm

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

LITAI MACHINERY

-

Voltage:

-

custom made

-

Dimension(L*W*H):

-

L12000xW2400xH1800mm

-

Power (kW):

-

270

-

Weight:

-

8000 KG

-

Flow channel type:

-

hanger type

-

Die head valid width:

-

950mm

-

screen changer:

-

hydraulic

-

Heating Way:

-

Aluminum-casted heater

-

water pressure:

-

2KG

-

Air Source:

-

0.3m³/hr

-

Barrel heating power:

-

48KW

-

Barrel heating material:

-

38CRMOAIA

-

Barrel cooling method:

-

air cooling

-

Hopper Capacity:

-

120KGS

*Pictures and related technical parameters of products will be updated continuously without prior notice.The right of final

interpretation of this information belongs to our company.

interpretation of this information belongs to our company.

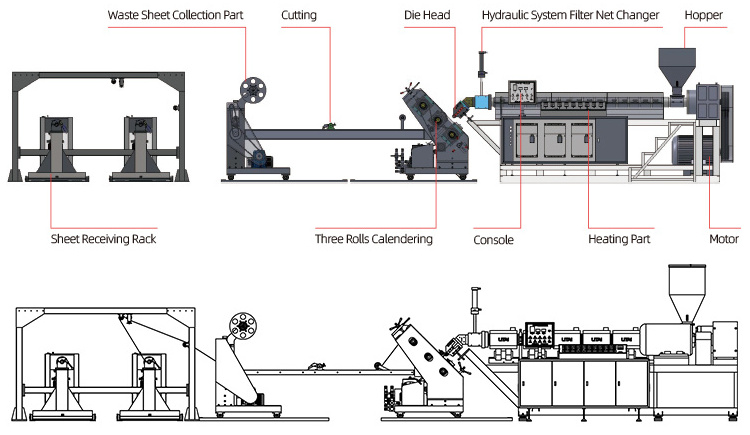

Product Paramenters

|

Model

|

TJ-750D

|

|

Suitable Sheet

|

PP, PS

|

|

Max. Sheet Width

|

770mm

|

|

Sheet Thickness Range

|

0.3-2.0mm

|

|

Screw Rod Dia. (Main machine)

|

95mm

|

|

Screw Rod Dia. (Auxiliary machine)

|

65mm

|

|

Screw L/D ratio (Main machine)

|

32:1

|

|

Screw L/D ratio (Auxiliary machine)

|

32:1

|

|

Main Motor Power

|

75kw

|

|

Max. Output

|

240kg/hr

|

|

Power supply

|

AC 380V, 50Hz, Three-phase, Four-wire

|

|

Dimension

|

L14000*W2600*H1800mm

|

|

Weight

|

About 9T

|

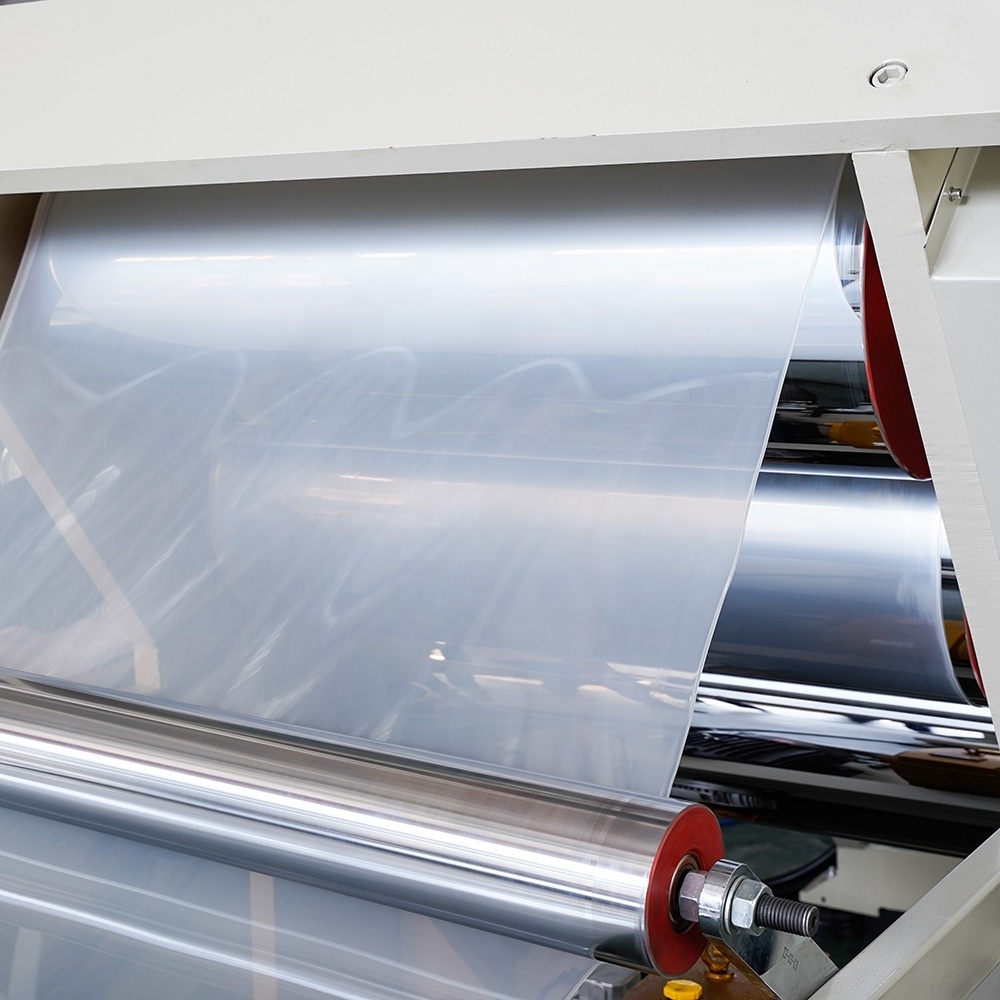

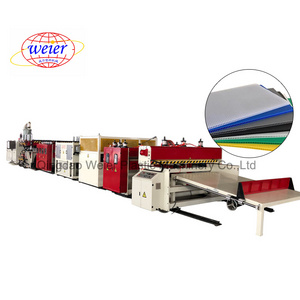

Product Display

Application:

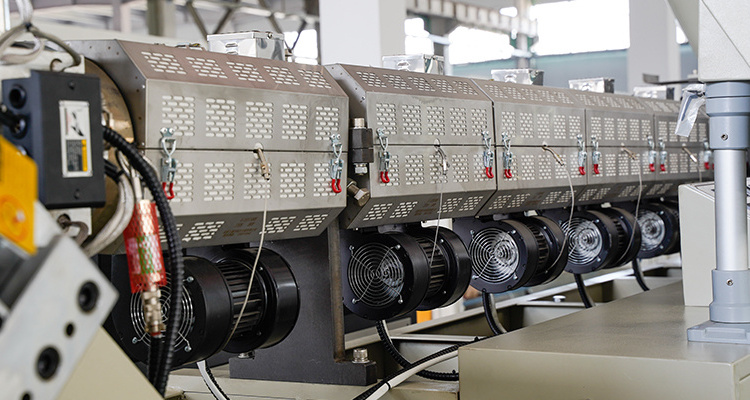

The sheet extruder is composed of extrusion, calendaring, traction and rolling. The main parts are abrasion resistant, resistant to corrosion, high-temperature resistant by high quality specially-treated. Low resistance force in die head extruding channel makes sheet thickness evenly, the internal spiral tank in three rollers ensures an effective cooling and it is easy to change and install net changer with the hydraulic pressure unit, no need to stop machine. The machine extrudes PP/PS granule to PP/PS sheet with single color, which is used for producing plastic products by plastic thermoforming machines, like cups, food container, trays, dishes, bowls, lids, etc.

Hot Searches