- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

>0.01%

-

Automatic Grade:

-

Semi automatic

-

Driven Type:

-

Pneumatic

-

Voltage:

-

220V 50Hz

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Ailusi

-

Dimension(L*W*H):

-

490*460*1500mm

-

Weight:

-

35 KG

-

Core Components:

-

filling head

-

Filling speed:

-

0-30BPM (adjustable)

-

Material:

-

Stainless Steel SUS304,SUS316

-

Hopper:

-

35L, SUS316L, equipped removable cover.

-

Structure:

-

Self-suction products to filling machine

-

Air Pressure:

-

0.5-0.8Mpa

Quick Details

-

Machinery Capacity:

-

2000BPH

-

Packaging Material:

-

Wood

-

Filling Material:

-

Beer, Other, Milk, Water, Oil, Juice

-

Filling Accuracy:

-

>0.01%

-

Automatic Grade:

-

Semi automatic

-

Driven Type:

-

Pneumatic

-

Voltage:

-

220V 50Hz

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Ailusi

-

Dimension(L*W*H):

-

490*460*1500mm

-

Weight:

-

35 KG

-

Core Components:

-

filling head

-

Filling speed:

-

0-30BPM (adjustable)

-

Material:

-

Stainless Steel SUS304,SUS316

-

Hopper:

-

35L, SUS316L, equipped removable cover.

-

Structure:

-

Self-suction products to filling machine

-

Air Pressure:

-

0.5-0.8Mpa

Product Description

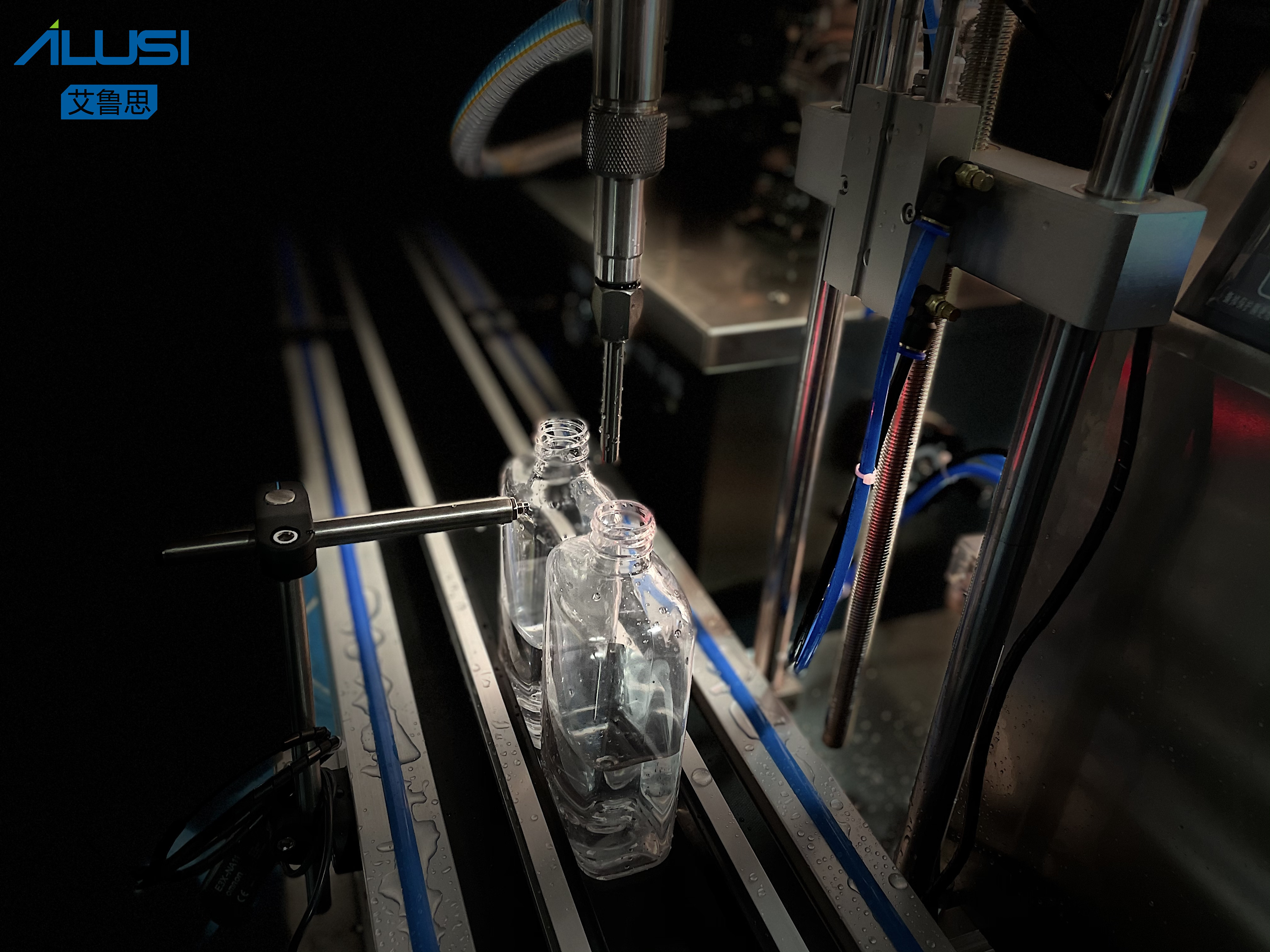

Desktop Ketchup Filling Machine Cosmetic Soft Ice Cream Lotion Jam Bottle Honey Filler

The Desktop Cosmetic Soft Ice Cream Lotion Jam Bottle Honey Ketchup Filling Machine is a compact and versatile device designed to streamline the filling process for various products. With its user-friendly interface and precise control system, this machine ensures accurate and efficient filling operations. It is suitable for filling bottles with soft ice cream, lotion, jam, honey, and ketchup. The machine is equipped with adjustable filling nozzles that accommodate different bottle sizes and can handle a wide range of viscosities. Its compact size makes it ideal for desktop use, saving valuable space in the production area. This filling machine is a reliable and convenient solution for small to medium-scale production lines, ensuring consistent and high-quality filling results.

FEATURES AT A GLANCE

1, Simple structure, convenient maintenance, reliable drive. With Self-suction function.

2, Import cylinder and pneumatic components, guarantee the reliability of the machine.

3, High measurement accuracy, no drip phenomenon.

4, Filling speed, can automatic uninterrupted filling.

5, Adopt imported 316L stainless steel materials, inside and outside polishing, conforming to GMP standards.

6, Feeding style: Normal gravity type.

Our Advantages

1.Efficiency: These machines are designed to automate the filling process, increasing production efficiency and reducing manual labor. This can result in higher output and consistent fill levels.

2.Accuracy: Modern filling machines are equipped with precise measurement systems to ensure accurate and consistent fill volumes, reducing product wastage and improving quality control.

3.Versatility: The machine you mentioned seems to be capable of filling various types of products, from ketchup to cosmetic products, ice cream, lotion, jam, and honey. This versatility makes it suitable for a range of industries.

4.Hygiene and Safety: Filling machines are often designed with sanitary standards in mind, ensuring the products are filled in a clean and safe environment. This is especially important for products like cosmetics and food items.

5.Reduced Contamination Risk: Automated filling minimizes the risk of contamination compared to manual filling, as it reduces human contact with the product.

6.Time Saving: Automating the filling process saves time compared to manual methods. This allows businesses to focus on other aspects of production and operations.

7.Consistency: These machines provide consistent fill levels across all bottles, ensuring uniformity in product appearance and quality.

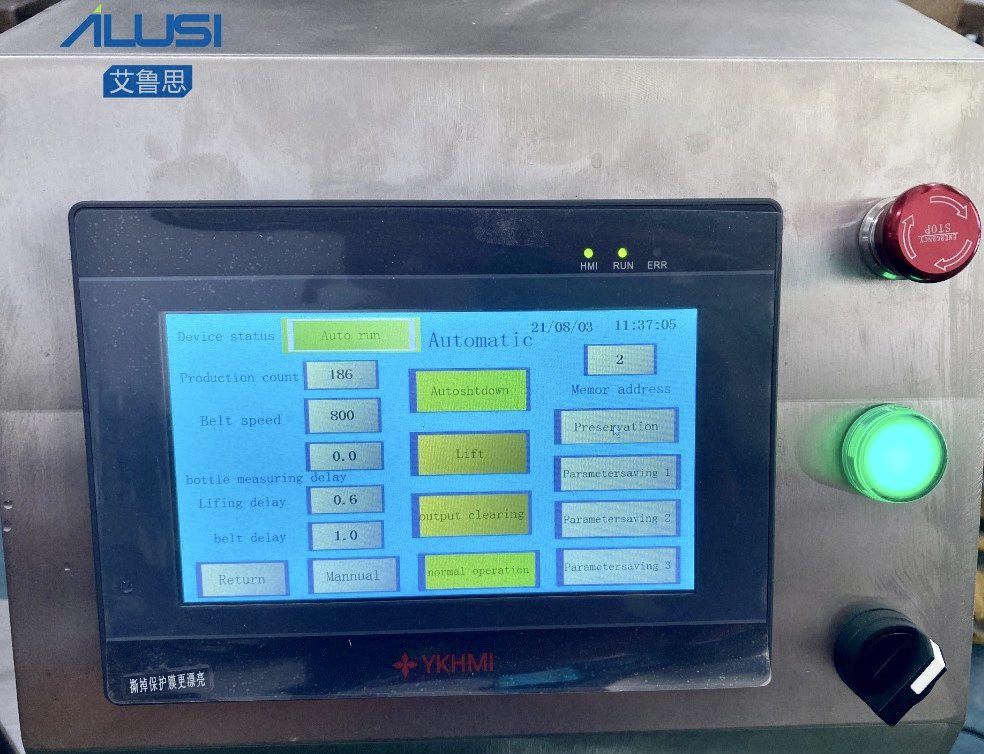

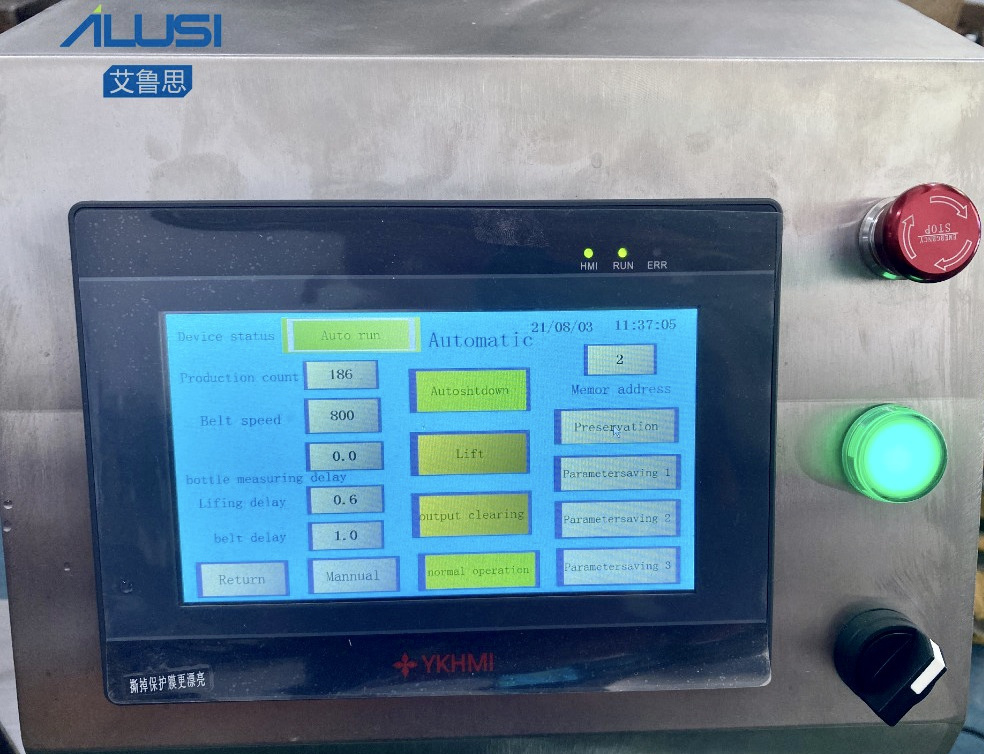

Parameter configuration

|

Filling range

|

5-1000ml

|

Heating method

|

Water circulation heating Hopper

|

|

|

Capacity

|

General 30L (can be customized)

|

Material stirring

|

spiral stirring

|

|

|

Filling accuracy

|

±1%

|

Filling speed

|

20-50b/min

|

|

|

Air source pressure

|

0.4-0.9Mpa

|

Gross weight

|

65KG

|

|

Details Images

Packing & Delivery

Factory Show

Service & FAQ

We provide Turn-key project service to customer.

1. Factory Layout design;

2. Factory Decoration based on GMP standard;

3. Formula of products;

4. Raw material etc;

5. Machine design, whole production line from A to Z;

6. Shipping service, FOB, CFR, CIF etc;

7. Installation service. Training service, Maintenance service.

2. Factory Decoration based on GMP standard;

3. Formula of products;

4. Raw material etc;

5. Machine design, whole production line from A to Z;

6. Shipping service, FOB, CFR, CIF etc;

7. Installation service. Training service, Maintenance service.

FAQ

Q1

: Are you a factory or trading company?

A1

: We are a factory specialized in Vacuum emulsifying mixer, filling machine, RO water treatment, capping machine and labeling machine…etc for cosmetic, pharmaceutical, chemical equipment over 20 years.

Q2

: How does your factory do regarding quality control?

A2

: Quality is priority. We always attach great importance to quality controlling from the beginning to the end. We support to inspect machine before shipment.

Q3

: What’s the guarantee and the after service if we purchase from you?

A3

: All the equipment ordered from us will provide one year guarantee from the delivery date.we could send our engineer to install or fix the machine locally.

Q4

: Are your machines difficult to operate? How do you teach us to use the machine?

A4

: Our machines are easy to operate, before delivery we will shoot instruction video to introduce machines' functions and to teach you how to use them.

Q5

: Can you make the machine according to customers' request?

A5

: Yes of course, OEM is acceptable. Most of our machines are customized design based on customer's requirements or situation.

Hot Searches