- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V/220V or customized

-

Dimension(L*W*H):

-

3200*1900*3600(customizable)

-

Power (kW):

-

23KW

-

Weight (KG):

-

3000 KG

-

Applicable Industries:

-

Floor heating board, integrated wall board, insulation board, insulation box, insulation water tank, water heater, kitchen board, steamed rice cabinet, other insulation filled foaming

-

Core Components:

-

Mixing head, Polyurethane special pump, Siemens motor magnet, PLC control, alkane gas detection system, Hot and cold thermostats, MSA gas detector

-

Product name:

-

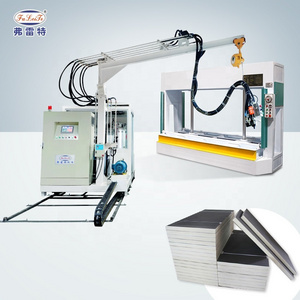

Thermal insulation polyurethane high-pressure foaming machine

-

Raw material:

-

Isocyanate and polyol(ISO and POLY)

-

Electrical configuration:

-

Siemens/Schneider

-

Equipment power:

-

23KW

-

Pouring flow(g/s):

-

350-1300

-

injection ratio:

-

1:3~3:1

-

Marketing Type:

-

Foaming machine strength manufacturer

-

System:

-

PLC+touch Screen

-

Usage:

-

Polyurethane foam filling

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Fuleite(FLT)

-

Machine Type:

-

Polyurethane Foaming Machine

-

Voltage:

-

380V/220V or customized

-

Dimension(L*W*H):

-

3200*1900*3600(customizable)

-

Power (kW):

-

23KW

-

Weight (KG):

-

3000 KG

-

Applicable Industries:

-

Floor heating board, integrated wall board, insulation board, insulation box, insulation water tank, water heater, kitchen board, steamed rice cabinet, other insulation filled foaming

-

Core Components:

-

Mixing head, Polyurethane special pump, Siemens motor magnet, PLC control, alkane gas detection system, Hot and cold thermostats, MSA gas detector

-

Product name:

-

Thermal insulation polyurethane high-pressure foaming machine

-

Raw material:

-

Isocyanate and polyol(ISO and POLY)

-

Electrical configuration:

-

Siemens/Schneider

-

Equipment power:

-

23KW

-

Pouring flow(g/s):

-

350-1300

-

injection ratio:

-

1:3~3:1

-

Marketing Type:

-

Foaming machine strength manufacturer

-

System:

-

PLC+touch Screen

-

Usage:

-

Polyurethane foam filling

FLT Thermal Insulation Filled high-pressure Polyurethane Foam making Machine For water heater

| Item/Model | FLT.B-06 | FLT.B-12 | FLT.B-28 | FLT.B-55 | FLT.B-107 |

| (g/s)Pouring flow | 20-220 | 150-550 | 350-1300g/s | 1000-2300g/s | 2000-5200g/s |

| Mixing head model | FLT07-10 | FLT10-14 |

FLT10-14

FLT12-18

|

FLT12-18

FLT16-25

|

FLT16-25 |

| (KW)Equipment power(380V,50HZ) | 18 | 23 | 32 | 56 | 108 |

| Metering pump model(A2FK,A2VK,A7VK) | 6 | 12 | 28 | 55 | 107 |

| Flowmeter (optional) | VC0.2 | VCG2FCP2 | VCG2 | VCG5FCP2 | VCG5FCP2 |

| Gas source | 0.6mpa(Nitrogen best) | ||||

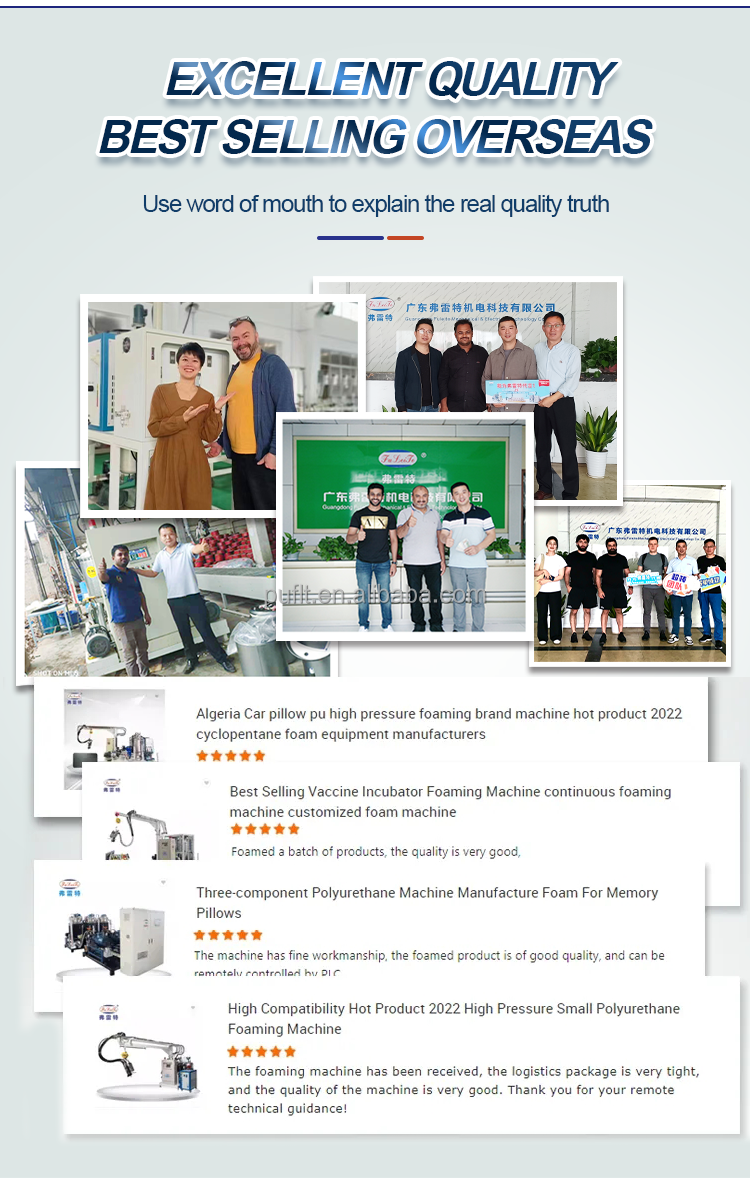

A) Are you a foam machine manufacturer?

Yes, we have 25 years of experience,serving 10,000+ PU projects,Top 3 in the domestic PU foam machinery industry, customizing a complete set of polyurethane foaming equipment in one stop,independent technology research and development, and choosing a large enterprise is more secure! B) What are the advantages of high pressure foaming machine compared to low pressure foaming machine?

The high-pressure foaming machine does not produce excess material, and the foaming quality is good, which will save about 5% to 10% of raw materials.

C) How do I get PU samples?

Before we receive the first order, the samples are free, you only need to bear the courier fee, we will refund the courier fee to you within your first order.

D) How about the shipping cost?

Sea freight is the best solution for bulk shipments. The exact shipping fee can only be confirmed after we know the details of quantity, weight and place of receipt .

E) What is the average delivery time?

For samples, the delivery time is about 7 days. For foaming equipment production, the delivery time is 20-30 days after receiving the deposit.

F) What payment methods do you accept?

You can pay to our bank account, TT or DP: 30% deposit in advance, 70% balance with copy of bill of lading.

G) How can we ensure that we receive quality pu foam equipment?

First of all, PU machine parts are purchased from Siemens, Schneider, Chint and other brand manufacturers. After the foam machine is assembled, we will use DOP to test the characteristics of the pu equipment, and only after debugging can it pass the factory and issue a certificate of conformity.

H) How is your warranty?

Our one-year warranty period and lifetime maintenance! At the same time, we have engineers with more than 10 years of experience in overseas after-sales service to ensure your smooth production.All machine parts can be ordered from us, we will provide perfect service according to your situation.