- Product Details

- {{item.text}}

Quick Details

-

Production Speed(Cycles/min):

-

30

-

Air Pressure(MPa):

-

30 MPa

-

Sheet Thickness(mm):

-

0.2 - 1.5 mm

-

Heating Power (kW):

-

121.6 kW

-

Air Comsumption(L/min):

-

10 L/min

-

Water Comsumption(L/min):

-

1 L/min

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

GtmSmart

-

Voltage:

-

380

-

Dimension(L*W*H):

-

9000*2200*2690mm

-

Weight (T):

-

12.5 T

-

Power(KW):

-

0

-

Product name:

-

Plastic Food Container Making Machine Plastic Fruit Box Making Machine

-

Function:

-

Automation

-

Applicable Material:

-

PS, PET, HIPS, PP, PLA, etc

-

Certificate:

-

CE, ISO

-

After-sales Service Provided:

-

Online support

-

Key words:

-

plastic food containe making machine

-

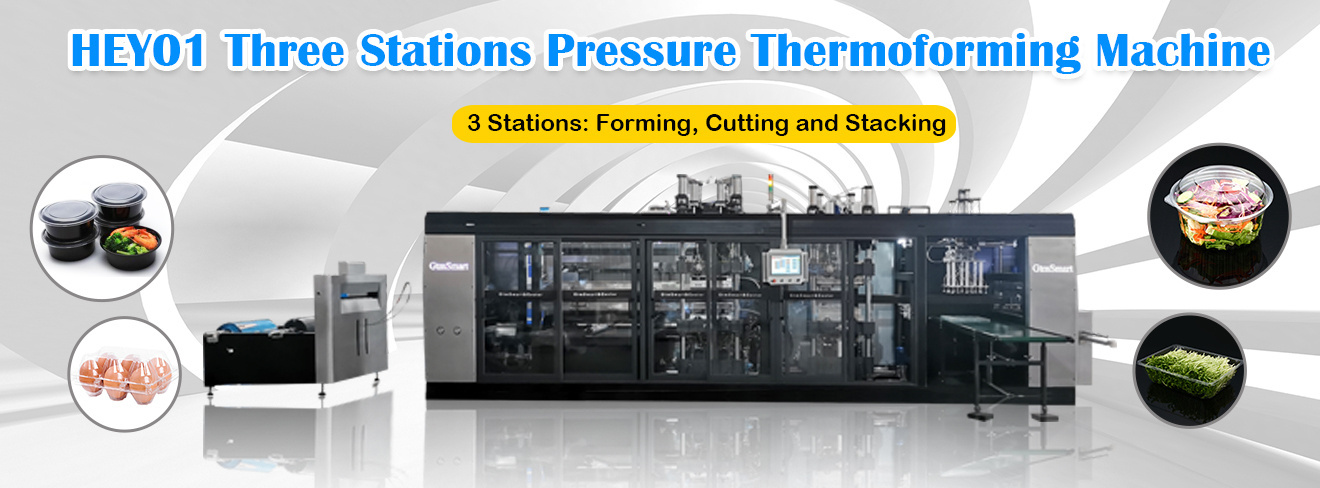

3 Stations:

-

Forming, Cutting, Stacking

-

Product Cooling Method:

-

By Water Cooling

-

Vacuum Pump:

-

UniverstarXD100

-

Price:

-

Factory Price

Quick Details

-

Max.Forming Height(mm):

-

100 mm

-

Forming Width (mm):

-

780 mm

-

Forming Length (mm):

-

600 mm

-

Production Speed(Cycles/min):

-

30

-

Air Pressure(MPa):

-

30 MPa

-

Sheet Thickness(mm):

-

0.2 - 1.5 mm

-

Heating Power (kW):

-

121.6 kW

-

Air Comsumption(L/min):

-

10 L/min

-

Water Comsumption(L/min):

-

1 L/min

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

GtmSmart

-

Voltage:

-

380

-

Dimension(L*W*H):

-

9000*2200*2690mm

-

Weight (T):

-

12.5 T

-

Power(KW):

-

0

-

Product name:

-

Plastic Food Container Making Machine Plastic Fruit Box Making Machine

-

Function:

-

Automation

-

Applicable Material:

-

PS, PET, HIPS, PP, PLA, etc

-

Certificate:

-

CE, ISO

-

After-sales Service Provided:

-

Online support

-

Key words:

-

plastic food containe making machine

-

3 Stations:

-

Forming, Cutting, Stacking

-

Product Cooling Method:

-

By Water Cooling

-

Vacuum Pump:

-

UniverstarXD100

-

Price:

-

Factory Price

| A. Product Application |

Plastic Food Container Making Machine Plastic Fruit Box Take Away Food Container Thermoforming Machine mainly for the production of variety plastic containers ( egg tray, fruit container, food container, package containers, etc) with thermoplastic sheets, such as PP,APET, PS, PVC, EPS, OPS, PEEK, PLA, CPET,etc.

| B. Product Features |

1. Mechanical, pneumatic and electrical combination, all working actions are controlled by PLC. Touch screen makes the operation convenient and easy.

2. Pressure And/Or Vacuum forming.

3. Upper and down mould forming.

4. Servo motor feeding, feeding length can be step-less adjusted. High speed and accurate.

5. Upper & lower heater, four sections heating.

6. Heater with intellectual temperature control system,which has high precision, uniform temperature, won’t be effected by outer voltage. Low power consumption (energy saving 15%), ensure the longer service life of heating furnace.

7. Forming and cutting unit mold open and close controlled by servo motor, products automatically count.

8. Products be stacked downward.

9. Data memorization function.

10. Feeding width can be synchronously or independently adjusted in electrical way.

11. Heater will automatically push-out when the sheet is over.

12. Auto roll sheet loading, reduce the working load.

| C. Product Parameter |

|

Model |

HEY01-6040 |

HEY01-7860 |

|

Max.Forming Area (mm 2 ) |

600x400 |

780x600 |

|

Working Station |

Forming, Cutting, Stacking |

|

|

Applicable Material |

PS, PET, HIPS, PP, PLA, etc |

|

|

Sheet Width (mm) |

350- 81 0 |

|

|

Sheet Thickness (mm) |

0.2-1.5 |

|

|

Max. Dia. Of Sheet Roll (mm) |

800 |

|

|

Forming Mould Stroke (mm) |

12 0 for up mold and down mold |

|

|

Power Consumption |

60-70KW/H |

|

|

Max. Formed Depth (mm) |

100 |

|

|

Cutting Mould Stroke (mm) |

12 0 for up mold and down mold |

|

|

Max. Cutting Area (mm 2 ) |

600x400 |

780x600 |

|

Max. Mold Closing Force (T) |

50 |

|

|

Speed (cycle/min) |

Max 30 |

|

|

Max. Capcity of Vacuum Pump |

200 m³ /h |

|

|

Cooling System |

Water Cooling |

|

|

Power Supply |

380V 50Hz 3 phase 4 wire |

|

|

Max. Heating Power (kw) |

140 |

|

|

Max. Power of Whole Machine (kw) |

1 6 0 |

|

|

Machine Dimension (mm) |

9000*2200*2690 |

|

|

Sheet Carrier Dimension (mm) |

2100*1800*1550 |

|

|

Weight of Whole Machine (T) |

12.5 |

|

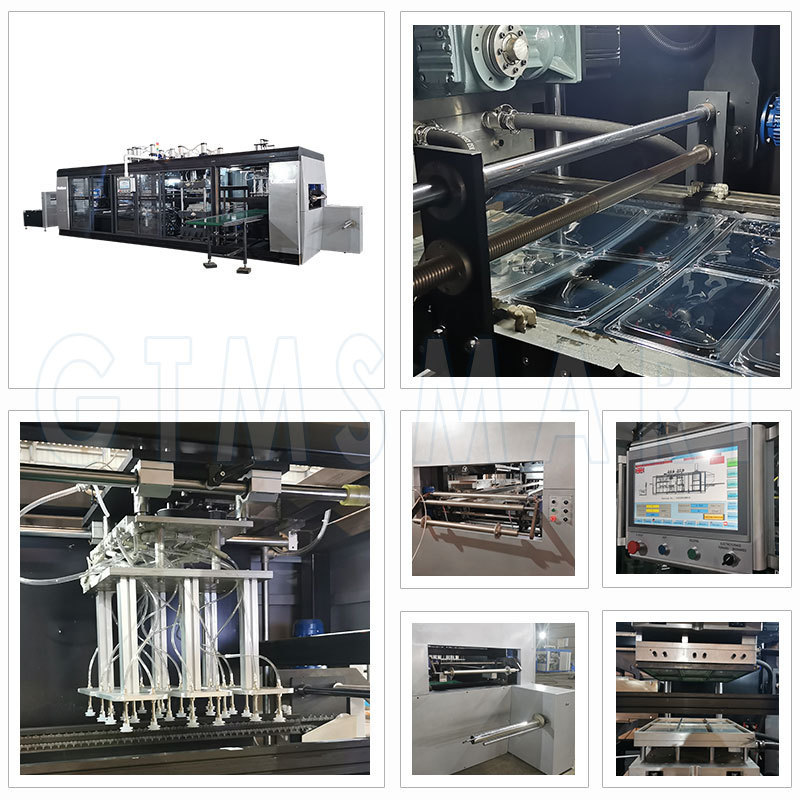

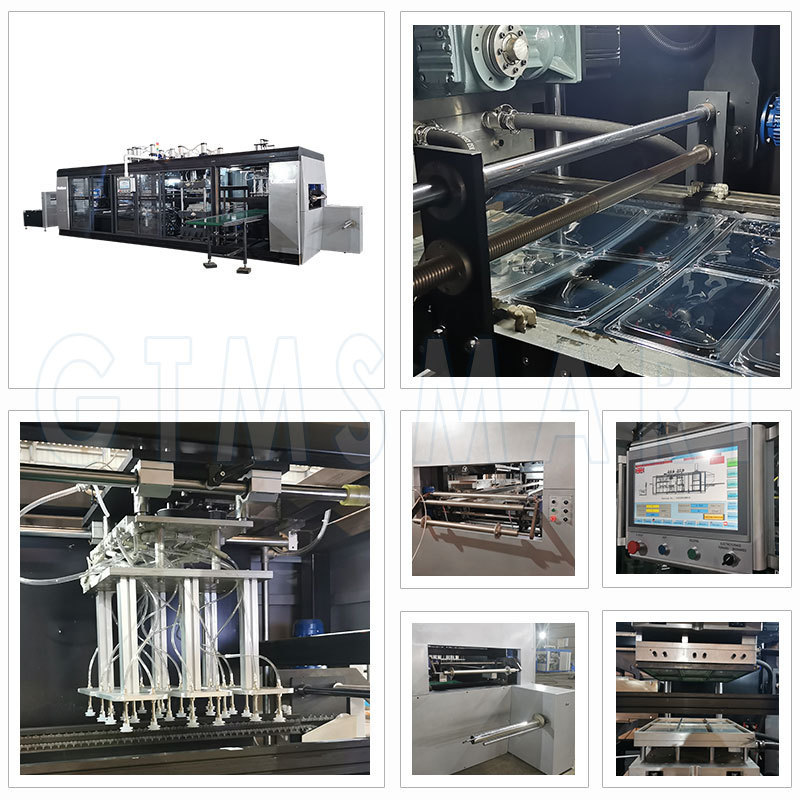

| D.Product Display |