- Product Details

- {{item.text}}

Quick Details

-

Machine Type:

-

Roller-Bending Machine

-

Raw Material:

-

Sheet / Plate Rolling

-

Extra Services:

-

Cut To Length

-

After-sales Service Provided:

-

Overseas service center available, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Online support, Video technical support

-

Voltage:

-

AC200V

-

Power:

-

5.0KW

-

Air compression:

-

0.4-0.6Mpa

-

Axis:

-

7

-

Item:

-

cnc letter channel steel strip bending machine

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

BOBO

-

Weight (KG):

-

900

-

Machine Type:

-

Roller-Bending Machine

-

Raw Material:

-

Sheet / Plate Rolling

-

Extra Services:

-

Cut To Length

-

After-sales Service Provided:

-

Overseas service center available, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Online support, Video technical support

-

Voltage:

-

AC200V

-

Power:

-

5.0KW

-

Air compression:

-

0.4-0.6Mpa

-

Axis:

-

7

-

Item:

-

cnc letter channel steel strip bending machine

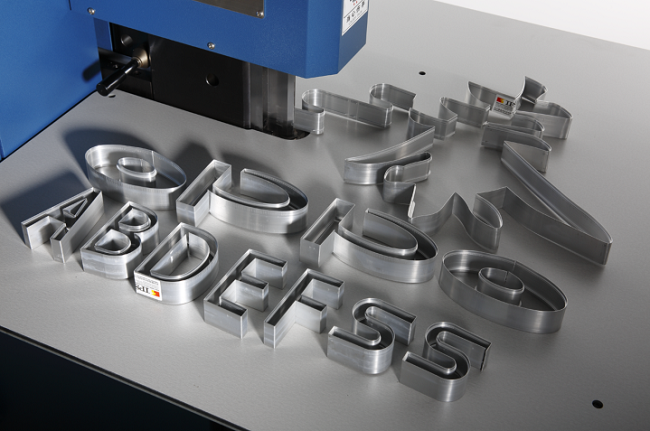

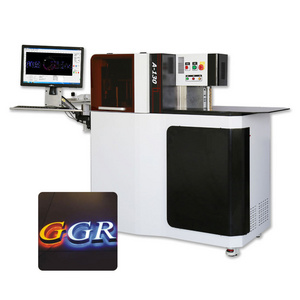

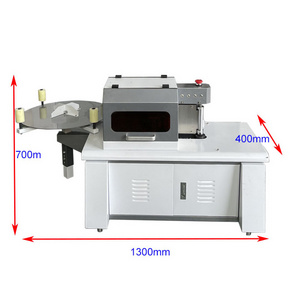

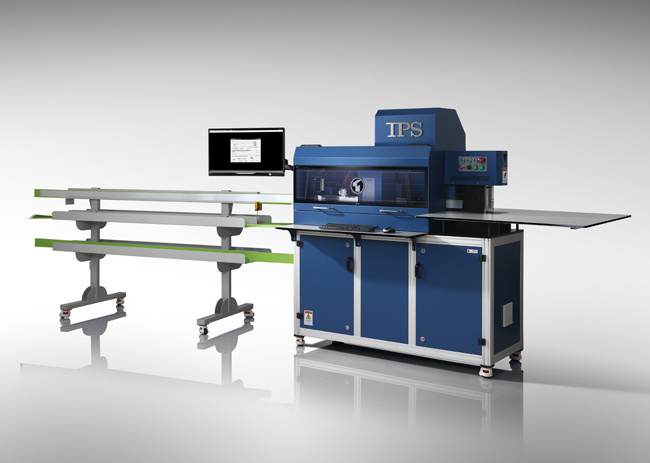

cnc letter channel steel strip bending machine with automatic cutting for AD

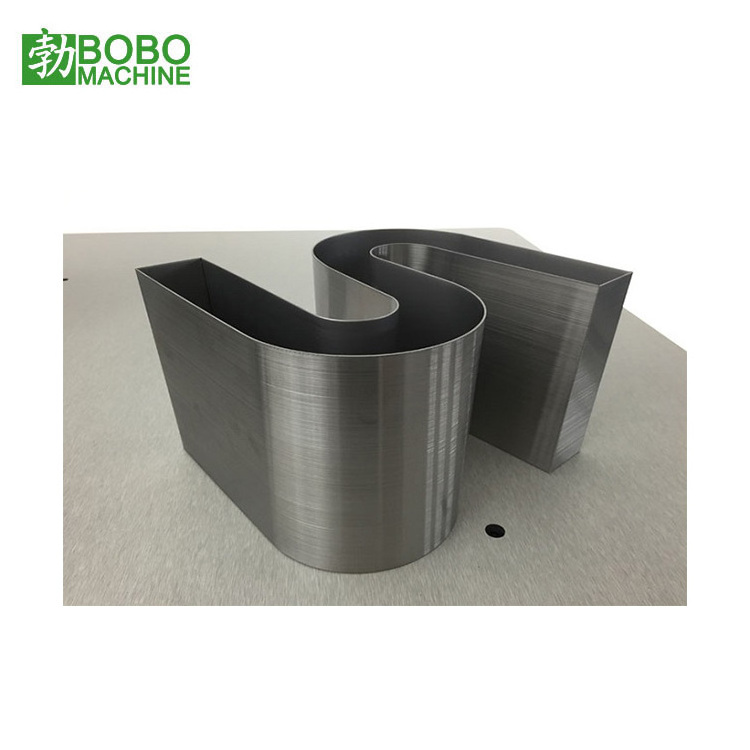

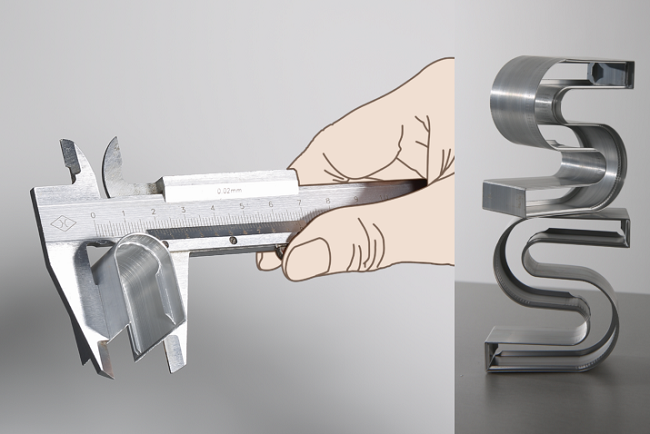

Through the world's first multi-bar bending system and mold quick-change system, the material is precisely bent, and the aluminum alloy, stainless steel coil, stainless steel strip, galvanized sheet and other materials are effectively realized. Super bending machine. It is the first choice for high-end LED characters, aluminum profile hook words, stainless steel characters, punch words, resin words and other characters.

Features

Bending mold quick change system: In order to adapt to the high quality bending requirements of different materials, we have developed a bending mold quick change system, which can be quickly and automatically replaced between flat material and aluminum material, completely solving multiple types of materials. The industry's problem of lossless precision bending on the same equipment.

Multi-bar bending system: On the basis of the telescopic double-bending bending system, a set of bending arbors with professional folding aluminum profiles can be used to realize free switching between flat material and aluminum material processing, and the folding is greatly improved. Bending forming degree.

Correction mechanism: The front feeding mechanism is used together with the multi-layer super-long guide frame to eliminate the feeding phenomenon and ensure a smoother feeding process.

Feeding mechanism: The alternating feeding mechanism is driven by servo control and double screw nut. It has strong distance, high precision and high speed transmission performance, ensuring the actual feeding accuracy reaches 0.1mm, eliminating the physical slipping phenomenon and pressure of the rolling feeding. Large indentation phenomenon.

Closed-loop control: With the unique full-closed detection, real-time monitoring of the actual displacement distance of the material, bending and micro-stretching, to achieve closed-loop control of the contour length of the graphic, to achieve accurate matching of the edge and the panel.

V-type industrial grade planing mechanism: intelligently control the groove depth, freely set the total depth of the groove, the single groove depth and the number of times; only the servo motor control, high-precision nut drive, with high groove speed and high precision, The advantage of constant torque; the V-groove has a smooth cut surface, no burr, uniform depth, and the R angle is not obvious when the R angle is folded, and the contour is clear and beautiful.

High-power and high-rigidity chamfering mechanism: High-power DC motor drive, featuring low noise, high speed, smooth processing and cutting surface.

Power supply AC200V

Machine power 5.0KW

Air compression 0.4-0.6MPa

Number of control axes 7 axes

Minimum fold U-shaped stainless steel (R7mm), aluminum profile (R20mm)

Minimum internal and external angular distance Stainless steel (4mm), aluminum profile (15mm)

Starting bending distance Stainless steel (4mm), aluminum profile (10mm)

Applicable materials Stainless steel, galvanized sheet, aluminum coil, aluminum profile

Material specifications Stainless steel (0.6-1.0mm), aluminum plate (1-2mm)

Processing height 20-175mm

Feeding method alternate feeding

Servo motor 4PCS

Stepper motor 3PCS

Equipment net weight 900Kg

Packaging:

Stable wooden package protects machine from strike and damage.

Wound plastic film keeps machine out of damp and corrosion.

Fumigation-free package helps the smooth customs clearance.

The big size machine will be fixed in container without package.

Shipping:

For LCL, we cooperated with reputable logistics team to send machine to sea port speedily and safely.

For FCL, we get the container and do container loading by our skillful workers carefully.

For forwarders, we have professional and long-term cooperated forwarders who can handle the shipment smoothly. Also we would like to have seamless cooperation with your forwarder at your convenience.

1 Professional and patient consulting service to help you find the suitable solution.

2 Further negotiation about the technical details, machine configuration, price basis, payment term and delivery time.

3 Powerful control of the machine production schedule and quality, and keep you posted about details in time.

4 Free training and accommodation in our plant during machine inspection. Or photos and video of the machine and package for your confirmation before shipment.

5 Quick and safe shipment as per your requirement including the booking ,container loading, and shipping documents.

6 For technical support, we can help you online by email and phone, also we can send technicians to your site if necessary.

7 For the spare parts, we will supply the parts for free during one year guarantee period, also the parts supplying at original cost after that.