- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.5-0.8mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Demma

-

Voltage:

-

380V, 50 Hz, 3 phase or according to your need.

-

Dimension(L*W*H):

-

11m x 1.2m x 1m

-

Weight:

-

5000 kg

-

Feeding width:

-

325mm

-

Name:

-

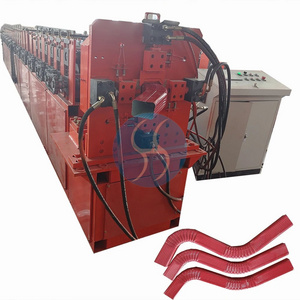

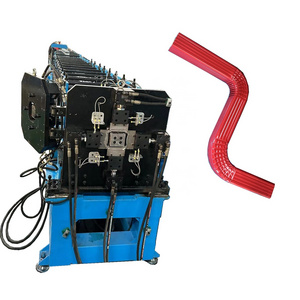

Downspout Elbow Machine

-

Color of Machine:

-

Customized

-

Operation Language:

-

Chinese/English/Customized

-

Quantity of forming rollers stations:

-

20-22

-

Diameter of forming rollers shafts:

-

60mm

-

Forming rollers material:

-

No.45 steel, coated with chromed treatment

-

Cutter material:

-

CR12 mould steel, with quenched treatment

-

Controlling system:

-

PLC and Converter

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

8-12 m/min

-

Rolling thinckness:

-

0.5-0.8mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Demma

-

Voltage:

-

380V, 50 Hz, 3 phase or according to your need.

-

Dimension(L*W*H):

-

11m x 1.2m x 1m

-

Weight:

-

5000 kg

-

Feeding width:

-

325mm

-

Name:

-

Downspout Elbow Machine

-

Color of Machine:

-

Customized

-

Operation Language:

-

Chinese/English/Customized

-

Quantity of forming rollers stations:

-

20-22

-

Diameter of forming rollers shafts:

-

60mm

-

Forming rollers material:

-

No.45 steel, coated with chromed treatment

-

Cutter material:

-

CR12 mould steel, with quenched treatment

-

Controlling system:

-

PLC and Converter

DESCRIPTION

* Downspout & Elbow Machine :

This roof gutter roll forming machine is for steel or aluminum sheet cold form industries. It can form rain gutter profiles according to customer’s requirement continuously, automatically cut to length. The equipment adopts PLC control, AC frequency and adjusting the speed technology, and it realizes the continuous automatically production. Therefore, it is really a new type of energy-saving and high-effective equipment for metal rain gutters. And it has many advantages, just like high forming speed, low noise, stable transmission, easy operation, good appearance and so on.

Other profile effects:

We can customized different shape profile according to your photo or drawing, pls feel free contact with us !!!

downpipe roll forming machine | downpipe making machine | downpipe roll former| downpipe production line |downpipe cold roll forming machine | downpipe making machinery | rain downpipe machine | rain gutter machine | rain gutter making machine | rain gutter forming machine | rain gutter former | rain gutter production line |rain gutter equipment

Downspouts Roll Forming Machine:

PARAMETERS

Main Technical Parameters of Automatic Square Downpipe Round Downspout Roll Forming Machine with Elbow

|

Quantity of forming rollers stations

|

20-22

|

|

Diameter of forming rollers shafts

|

60mm

|

|

Roll Forming Speed

|

8-12m/min

|

|

Forming rollers material

|

No.45 steel, coated with chromed treatment

|

|

Cutter material

|

CR12 mould steel, with quenched treatment

|

|

Controlling system

|

PLC and Converter

|

|

Electric Power requirement

|

Motor of roll forming machine: 5.5kw

|

|

|

Motor of sawing cutter: 3kw

|

|

|

Motor of elbow machine: 1.5kw

|

|

Electric voltage

|

According to customer’s requirement

|

DETAIL IMAGES

Details of Automatic Square Downpipe Round Downspout Roll Forming Machine with Elbow

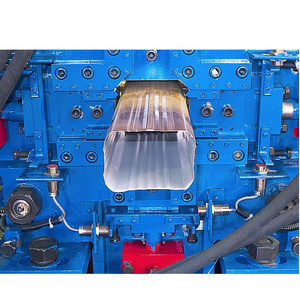

Main Frame & Roll Forming:

With feeding material guide, body frame made of steel type H450 by welding

Side wall thickness: q235 t18mm ;

45# steel rollers, CNC lathes, heat treatment, hard chrome plated

With a thickness of 0.04mm

Shaft diameter=ф75mm, precisely machined

Gear/gear drive to form about 14-step

Main motor=11KW, frequency control

All screws are grade 8.8

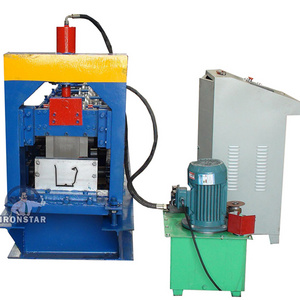

After The Hydraulic Cutting Device:

Post to cut, stop cutting, two pieces type of cutting design, no blanking

Hydraulic motor: 7.5kW ;

Cutting tool material: Cr12MoV, heat treatment up to HRC58-62 degrees

Cutting power is provided by the main engine hydraulic station

Hydraulic motor: 7.5kW ;

Cutting tool material: Cr12MoV, heat treatment up to HRC58-62 degrees

Cutting power is provided by the main engine hydraulic station

Advantages :

Customized profile and suggestions.

Material handling solutions.

Logo Marking.

Full safety protection with cover guard, emergency switches, mistake proofing program.

Customized profile and suggestions.

Material handling solutions.

Logo Marking.

Full safety protection with cover guard, emergency switches, mistake proofing program.

PACKING & SHIPPING

1.Packing type:wooden case,also be packaged according to customer requirements.

2.We will send photos and videos for your reference before shipment.

WHY CHOOSE US

Henan Demma Electronic Equipment Co., Ltd., is a supplier of machinery.We have exported more than 100 countries like USA, Mexico,Canada, Spain, Russia, Singapore, Thailand, India etc . Our products provide customer more convenient in their business and expect to have more cooperate in future.What we offer:

1) Good quality control

2) Highly competitive prices

3) state-of-art technology products

4) Best professional team of lifestyle consumer electronics.

5) Smooth communication

6) Effective OEM&ODM service

FAQ

Q1: How long is the warranty?

A1: We guarantee a 12-month after-sale service .Any problem when using ,call or mail us ,we will advise on technically sound methods .If needed ,we will provide free accessories

Q2: Can I have my own customized product?

A2: Yes, your customized requirements for color, logo, design, package, carton mark, etc. are welcome

Q3: How can I get sample and how long will it take?

A3: Sample policy is different for different items. Please kindly contact us to get details.

Q4: What's the MOQ?

A4: MOQ is different for different items, please kindly contact us for confirming.

Q5: How do I pay for my purchase order?

A5: T/T, L/C at sight, Western Union, MoneyGram

Q6: What is your terms of payment?

A6: For regular order, T/T 30% as deposit, and 70% before Shipment. We'll show you the photos of the products and packages before you pay the balance

Q7: How about your delivery time?

A7: Generally, It will take about 7~15 days to send goods out. The specific delivery time depends on the items and the quantity of your order

Hot Searches