- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

Onsite Condition

-

Dimension(L*W*H):

-

based on furnace size

-

Weight (T):

-

10 T

-

Power (kW):

-

260

-

name:

-

bogie hearth quenching furnace

-

rate power:

-

120KW

-

Effective working size:

-

3000X1300X1300mm

-

Control zone:

-

2 zones, independent control

-

Temperature uniformity:

-

±10℃

-

Heating element:

-

0Cr27AL7Mo2 (strip)

-

refractory lining:

-

silicate aluminum fiber precompressed blocks

-

bogie protection system:

-

limit switch at both ends

-

furnace door lifting mechanism:

-

electrical hoist or manual system

-

electrical components:

-

Schneider, CHINT or other quality components

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Marketing Type:

-

New Product 2023

-

Brand Name:

-

WONDERY

-

Voltage:

-

Onsite Condition

-

Dimension(L*W*H):

-

based on furnace size

-

Weight (T):

-

10 T

-

Power (kW):

-

260

-

name:

-

bogie hearth quenching furnace

-

rate power:

-

120KW

-

Effective working size:

-

3000X1300X1300mm

-

Control zone:

-

2 zones, independent control

-

Temperature uniformity:

-

±10℃

-

Heating element:

-

0Cr27AL7Mo2 (strip)

-

refractory lining:

-

silicate aluminum fiber precompressed blocks

-

bogie protection system:

-

limit switch at both ends

-

furnace door lifting mechanism:

-

electrical hoist or manual system

-

electrical components:

-

Schneider, CHINT or other quality components

Product Application

High Temperature Bogie Hearth Electric Resistance Heat Treatment Furnace is state standard energy saving cyclic furnace. It is a fiber structure saving 60% power consumption. It is among the first manufacturers to employ compound high aluminum porcelain nail group, trolley anti-explosion sealing bricks, automatic sealing trolley and furnace door, and integrated rail. This series furnace is applicable to the quenching, annealing and aging treatment of high chrome parts, high manganese cast parts, cast iron, rolls, steel balls, 45# steel parts and others.

bogie hearth furnace for quenching

bogie hearth furnace for quenching

bogie hearth furnace for quenching

|

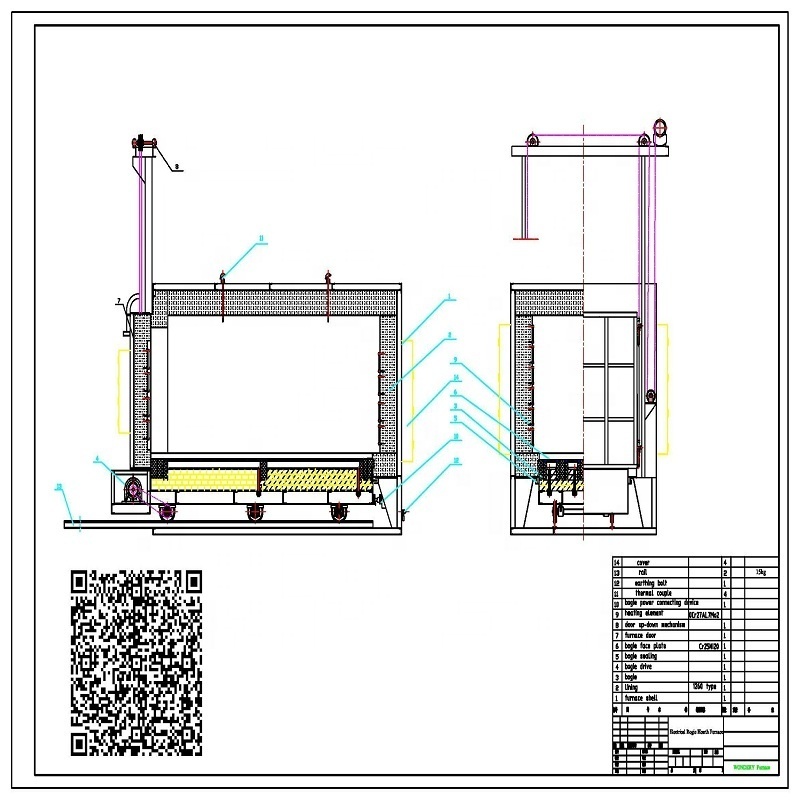

SPECIFICATIONS FOR

WONDERY Professional Factory Made 1200 Degree Electrical Bogie Hearth Trolley Type Quenching Furnace For Mold Steel

|

|

|

|

|||

|

Temperature control

system

|

Rated Temperature

|

℃

|

1200

|

|||

|

|

Empty furnace temperature rise time

|

hour

|

1.5

|

|||

|

|

Furnace body exterior temperature

|

℃

|

≤ 25 + room temperature

|

|||

|

|

Temperature control system precision

|

℃

|

≤±1

|

|||

|

|

Uniformity of furnace temperature

|

℃

|

≤±10

|

|||

|

|

Voltage

|

|

according to customer's

|

|||

|

|

Temperature Control Method

|

|

PID

|

|||

|

|

Components brand

|

|

Siemens, Schneider, CHINT(or other quality domestic or overseas brand)

|

|||

|

Mechanical system

|

door lifting mechansim

|

|

electric hoist

|

|||

|

|

bogie driving system

|

|

reducing motor

|

|||

|

|

door and bogie moving speed

|

m/min

|

6-8

|

|||

|

Refractory lining

|

hearth lining

|

|

aluminum silicate fiber

|

|||

|

|

bogie lining

|

|

refractory brick

|

|||

Main Features

1) High Temperature Bogie Hearth Electric Resistance Heat Treatment Furnace has a shell of welded steel plates and sectional steel. The structure is of thick material.

2) The hearth wall lining is an all-fiber structure, saving about 60% of power consumption compared with the traditional brick hearth.

3) Heating components: high temperature resistance alloy wires and strips.

4) Low noise, energy-friendliness, and stable performance.

5) Advanced CAD design.

6) Years of experiences in heat treatment process.

Heating Elements

The 0Cr27AL7Mo2 resistance spiral-shape alloy resistance strips are mounted in 2 side walls, back wall, furnace door and bogie bottom.

The resistance strips are produced through special molds, and are installed in the furnace wall by porcelain nails. And there is a

porcelain gasket between the fiber wall and the resistance strips to avoid short-circuit.

Bogie Moving Mechanism

The bogie has a self-moving method. The reducing gear drives the bogie wheel to move. The bogie movement is smooth and stable.

Control Cabinet

Name: GGD type electrical control cabinet

Brand: CHINT, SIEMENS, Schneider, Omron, etc.

Original: China, Germany, French, Japan, etc.

|

Model

|

Hearth Size (mm)

L*W*H

|

Rated Power (kw)

|

Empty Furnace Rising Time (h)

|

Max Loading Capacity (kg)

|

|

RT2-30-9

|

950×500×450

|

30

|

2.5

|

500

|

|

RT2-45-9

|

1100×600×400

|

45

|

2.5

|

800

|

|

RT2-65-9

|

1200×600×450

|

65

|

2.5

|

1000

|

|

RT2-75-9

|

1500×750×600

|

75

|

2.5

|

1500

|

|

RT2-90-9

|

1800×900×600

|

90

|

2.5

|

2500

|

|

RT2-105-9

|

1800×900×650

|

105

|

2.5

|

3500

|

|

RT2-120-9

|

2000×900×700

|

120

|

2.5

|

4000

|

|

RT2-135-9

|

2000×1000×750

|

135

|

2.5

|

4200

|

|

RT2-150-9

|

2200×1000×800

|

150

|

2.5

|

5000

|

|

RT2-180-9

|

2200×1050×750

|

180

|

2.5

|

6000

|

|

RT2-200-9

|

2400×1200×800

|

200

|

2.5

|

6500

|

|

RT2-220-9

|

2500×1300×900

|

220

|

2.5

|

7000

|

|

RT2-240-9

|

2500×1400×900

|

240

|

2.5

|

8000

|

|

RT2-250-9

|

2800×1500×900

|

250

|

2.5

|

9000

|

|

RT2-280-9

|

3000×1500×900

|

280

|

2.5

|

10000

|

|

RT2-300-9

|

3000×1530×950

|

300

|

2.5

|

11000

|

|

RT2-320-9

|

3200×1530×950

|

320

|

2.5

|

12000

|

|

RT2-350-9

|

3500×1500×1200

|

350

|

2.5

|

15000

|

|

RT2-380-9

|

4000×1500×1200

|

380

|

2.5

|

18000

|

|

RT2-400-9

|

4500×1500×1200

|

400

|

3

|

20000

|

|

RT2-420-9

|

4500×1600×1200

|

420

|

3

|

22000

|

|

RT2-450-9

|

5200×1500×1200

|

450

|

3

|

25000

|

|

RT2-480-9

|

5500×1500×1200

|

480

|

3

|

28000

|

|

RT2-500-9

|

6000×1500×1200

|

500

|

3

|

30000

|

|

RT2-540-9

|

6500×1800×1200

|

540

|

3

|

35000

|

|

RT2-600-9

|

7000×1800×1200

|

600

|

3

|

38000

|

|

RT2-650-9

|

7200×2000×1200

|

650

|

3

|

40000

|

|

RT2-700-9

|

7500×1800×1800

|

700

|

3

|

42000

|

|

RT2-800-9

|

8500×2000×1500

|

800

|

3.5

|

52000

|

|

RT2-900-9

|

9000×2200×1600

|

900

|

3.5

|

60000

|

2. What information should the customer provide to get an accurate quotation from us?

The customer should provide the related technical requirements, drawings, pictures, industrial voltage, planned output, etc.

3. What is the payment term?

The payment term is 40% down payment, and 60% before delivery (T/T mode).

4. What is the delivery time?

The delivery time of the machine is 15-30 days after receipt of down payment.