- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

RD

-

Weight:

-

40000 KG, 1.5-65t

-

Feeding size:

-

20-25mm

-

Capacity:

-

0.65-90t/h

-

Model:

-

Customized

-

Power:

-

18.5-800KW

-

Product name:

-

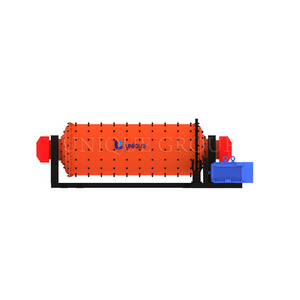

Ball mill

-

Dimension(L*W*H):

-

According to the model

Quick Details

-

Marketing Type:

-

New Product

-

Capacity(t/h):

-

0.65-90t/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

RD

-

Weight:

-

40000 KG, 1.5-65t

-

Feeding size:

-

20-25mm

-

Capacity:

-

0.65-90t/h

-

Model:

-

Customized

-

Power:

-

18.5-800KW

-

Product name:

-

Ball mill

-

Dimension(L*W*H):

-

According to the model

Products Description

Working principle:

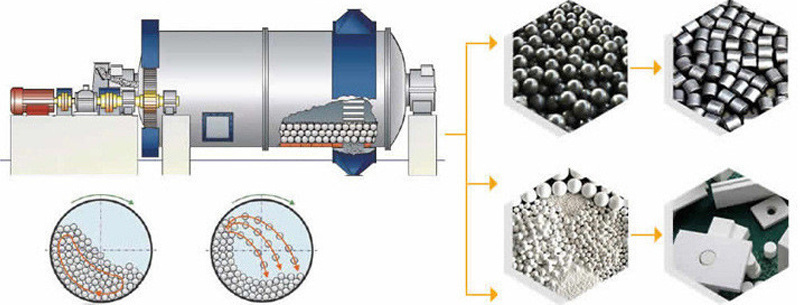

The ball mill is horizontal cylindrical rotation device,driving by brim gearwheel, there are two chambers and grid. Material goes into the first chamber through the feeding inlet, inside the first chamber, there are stage liners and ripple liners as well as steel balls with various kinds.The shell rotates which generates eccentricity, this force brings balls to a certain height and then balls drop down by gravity, which will impact and grind the material. After the primary grinding in the first chamber, material goes into the second chamber through segregate screen, in the second chamber, there are fiat liners and steel balls, after the secondary grinding, material is discharged through the discharge screen.

Product Paramenters

Recommend Products

Advantages

1. The lining can be replaced.

2. Mineral ball mill is an efficient tool for grinding many materials into fine powder.

3. Two ways of grinding: the dry way and the wet way.

4. Ultimate particle size depends entirely on how hard the material you’re grinding is.

5. As the barrel rotates, the material is crushed between the individual pieces of grinding media that mix and crush the product into fine powder over a period of several hours.

Hot Searches