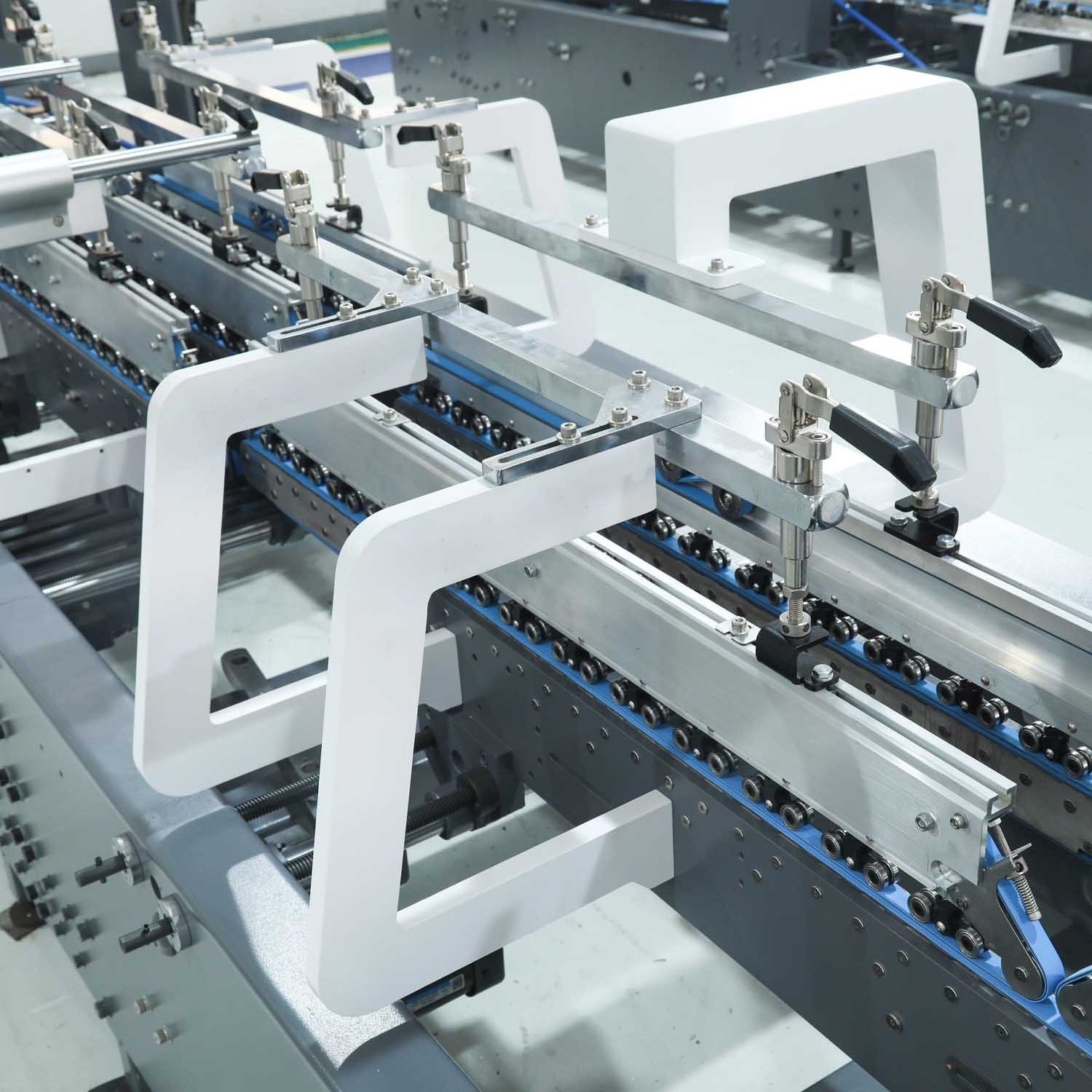

* 6pcs Adjustable feeding belts to ensure easy adjustment, stable and smoothly feeding.

* Continuously Variable Speeder to ensure feeding internal and stable transmission.

* One-touch Pneumatic knife, easy for the adjustment of feeding belts.

- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

12*1.45*1.45

-

Weight:

-

4500 KG

-

Model:

-

AS-650/800/1100

-

Bearings:

-

NSK Japan

-

Belt:

-

Nitta

-

Max Liner Speed:

-

300m/min

-

Box forming:

-

Straight Line Box& Auto-bottom Lock Box

-

Max feeding width:

-

650/800/1100mm

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Paper material:

-

210-800gsm Cardboard Paper Box

-

Function:

-

Pre-folding & Crash Lock Bottom Machine

-

Usage:

-

Paperboard Folding Gluing

Quick Details

-

Voltage:

-

3P 380V 50HZ

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Rolam

-

Dimension(L*W*H):

-

12*1.45*1.45

-

Weight:

-

4500 KG

-

Model:

-

AS-650/800/1100

-

Bearings:

-

NSK Japan

-

Belt:

-

Nitta

-

Max Liner Speed:

-

300m/min

-

Box forming:

-

Straight Line Box& Auto-bottom Lock Box

-

Max feeding width:

-

650/800/1100mm

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Paper material:

-

210-800gsm Cardboard Paper Box

-

Function:

-

Pre-folding & Crash Lock Bottom Machine

-

Usage:

-

Paperboard Folding Gluing

Product Description

Automatic Pre-folding Crash Lock Bottom Folder Gluer(GK-AS)

* Adopt synchronous belt transmission and electronic continuously variable speeder, domestic standard electronic components.

* Feeding section adopt independent motor control, stable and easy to control and operate.

* Widely used in food, medicine, cosmetics, stationery and other ordinary cartons, process and glue for all kinds of bottom-locked cartons.

* Feeding section adopt independent motor control, stable and easy to control and operate.

* Widely used in food, medicine, cosmetics, stationery and other ordinary cartons, process and glue for all kinds of bottom-locked cartons.

Specification

|

AS TECHNICAL PARAMETERS

|

|

|

|

|||

|

MODEL

|

650

|

800

|

1100

|

|||

|

Paper Material

|

Cardboard 210-800 GSM,E/F E/F Flute

|

|

|

|||

|

Max Speed

|

300 M/Min

|

|

|

|||

|

Max Thickness of Folded Box

|

12 MM

|

12 MM

|

12 MM

|

|||

|

Way of Folding

|

Fold 1 and fold 3 are 180°and 135°,fold 2 and fold 4 are 180°

|

|

|

|||

|

Power Supply

|

3P 380V 50HZ

|

|

|

|||

|

Blank Width

|

650 MM

|

800 MM

|

1100 MM

|

|||

|

Length X Width X Height

|

12 X 1.08 X 1.4 M

|

12 X 1.23 X 1.4 M

|

12 X 1.58 X 1.4 M

|

|||

|

Net Weight

|

4 T

|

4.5 T

|

5 T

|

|||

|

Total Power

|

12 KW

|

14 KW

|

15 KW

|

|||

Details Images

Feeding Section

Pre-folding Section

* Double-board structure with a set of pre-folding knife.

* Pre-fold angle is 180°and 135°, especially suitable for small but high cartons, more satisfactory while in mass production

* Pre-fold angle is 180°and 135°, especially suitable for small but high cartons, more satisfactory while in mass production

Folding and Closing Section

* Equipped with the driving belt, folding belts have corrective function, extension work, make the box forming more stable.

Trombone Section

* Adjust the pressure easily and reliably to ensure the gluing quality; Equipped with pneumatic counting device which makes the counting conveniently.

* Equipped with independent speeder. The operator can set the collecting speed.

Conveyor

* Equipped with one-touch pneumatic pressure adjustment, easy operation.

* Has two functions:

1.waiting, when feeding is paused, press will auto enter into waiting state

2.Travel switch, pause the machine in case of wrong collecting

* Has two functions:

1.waiting, when feeding is paused, press will auto enter into waiting state

2.Travel switch, pause the machine in case of wrong collecting

Hot Searches