- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Ordos

-

Model Number:

-

SG-5

-

MOQ:

-

280 tons

-

Sample:

-

Freely Offered

Quick Details

-

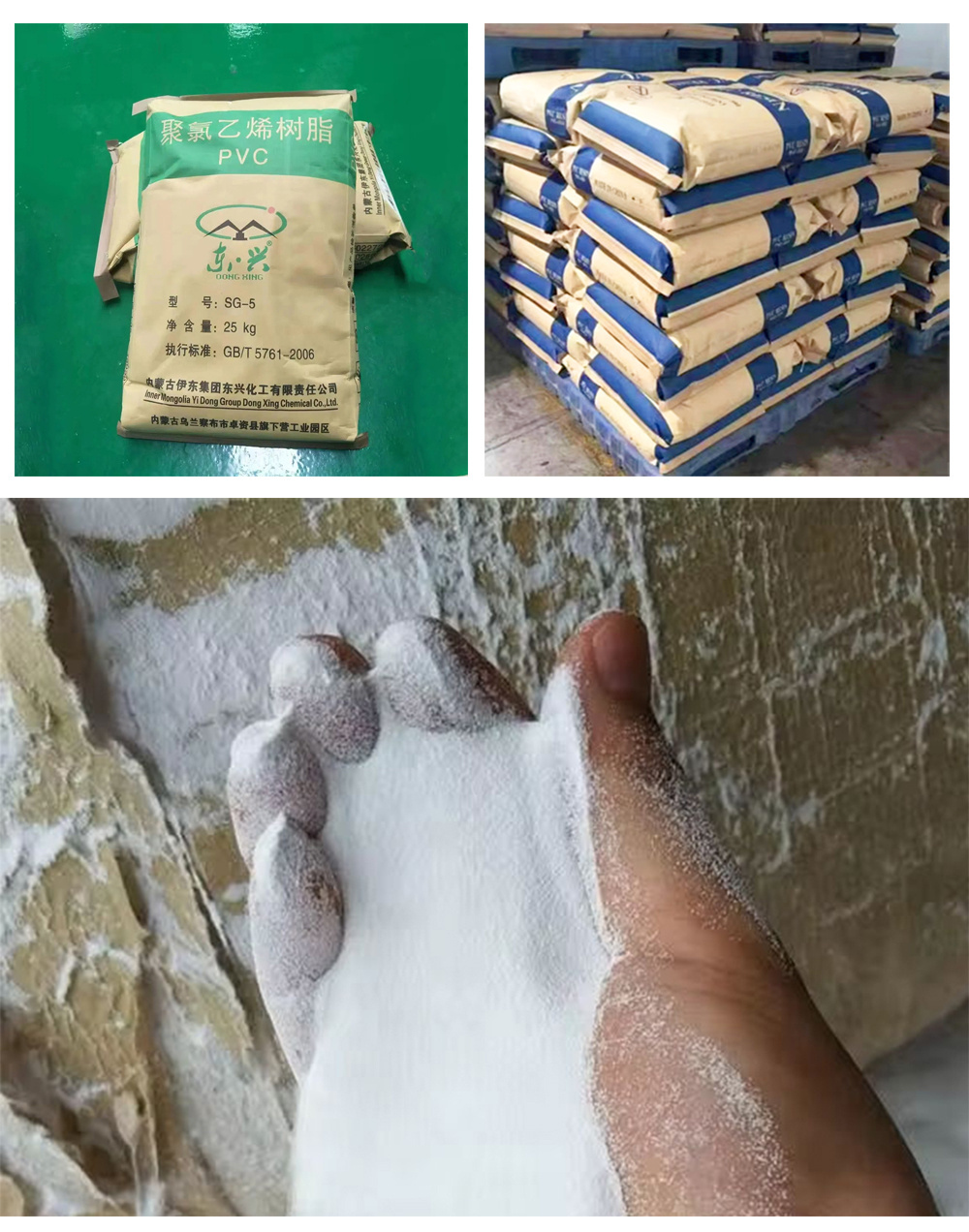

color:

-

White

-

Shape:

-

Powder

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Ordos

-

Model Number:

-

SG-5

-

MOQ:

-

280 tons

-

Sample:

-

Freely Offered

A: Property

Polyvinyl chloride is high molecular compounds polymerized by vinyl chloride monomer(VCM) with structural element as CH2-CHCLn,degree of polymerization usually as 590-1500.

In the process of re-polymerization ,affected by kinds of factors such as the polymerization process, reaction conditions, reactant composition, additives etc.it can produce eight different types of PVC resin performance is different. According to residual content of vinyl chloride in polyvinyl chloride resin, is can be divided into :commercial grade, food hygiene grade and medical application grade in appearance, polyvinyl chloride resin is white powder or pellet.

B:Application

Polyvinyl chloride resin is widely used in production of polyvinyl chloride boardy leatheroid, paint and adhesive agents,tec. Paint and adhesive .

Division according to application:

1.Building materials: such as UPVC tubing, UPVC pipes, panel and section bars;

2.Packing materials.;

3.Electronic materials: such as electronic wires, cables,adhesive tapes and bolts.;

4.Furniture and decorating materials,etc.;

5.Others: leatheroid, medical disposable products, antiseptic paint,etc.

| Psate/emulslon PVC Resin for artificial leather | |||

| Items | SG-3 | SG-5 | SG-8 |

| K value | 72-71 | 68-66 | 59-55 |

| Viscosity number ml/g | 135-127 | 118-107 | 86-73 |

| Average degree of polymerization | 1370-1251 | 1135-981 | 740-650 |

| Number of impurity particle | ≤16 | ≤16 | ≤20 |

| Volatile substance | ≤0.3 | ≤0.4 | ≤0.4 |

| Volatile conten | ≥0.45 | ≥0.48 | 0.50 |

| Whiteness(160℃,10min)% | ≥78 | ≥75 | ≥75 |

| Package | 25 kgs dobble layers bag | ||

Polyvinyl chloride has the outstanding characteristics of abundant raw materials (oil, limestone, coke, salt and natural gas), mature manufacturing process, low price, and wide range of uses. It has become the second largest general-purpose resin in the world after polyethylene resin. 29% of the world's total synthetic resin consumption. Polyvinyl chloride is easy to process and can be processed by molding, laminating, injection molding, extrusion, calendering, blow molding, etc. Polyvinyl chloride is mainly used to produce soft plastic products such as artificial leather, films, and wire sheaths, as well as hard plastic products such as plates, doors and windows, pipes and valves. Polyvinyl chloride is flame-retardant (flame retardant value above 40), high chemical resistance (resistant to concentrated hydrochloric acid, 90% sulfuric acid, 60% nitric acid and 20% sodium hydroxide), mechanical strength And the advantages of good electrical insulation. But its heat resistance is poor, with a softening point of 80°C, it starts to decompose and change color at 130°C, and precipitate HCI.

Due to its high chemical stability, it can be used to make anti-corrosion pipelines, pipe fittings, oil pipelines, centrifugal pumps and blowers, etc. Polyvinyl chloride hard boards are widely used in the chemical industry to make linings for various storage tanks, corrugated boards for buildings, door and window structures, wall decorations and other construction materials. Due to its excellent electrical insulation performance, it can be used to manufacture plugs, sockets, switches and cables in the electrical and electronic industries. In daily life, polyvinyl chloride is used to make sandals, raincoats, toys and artificial leather!