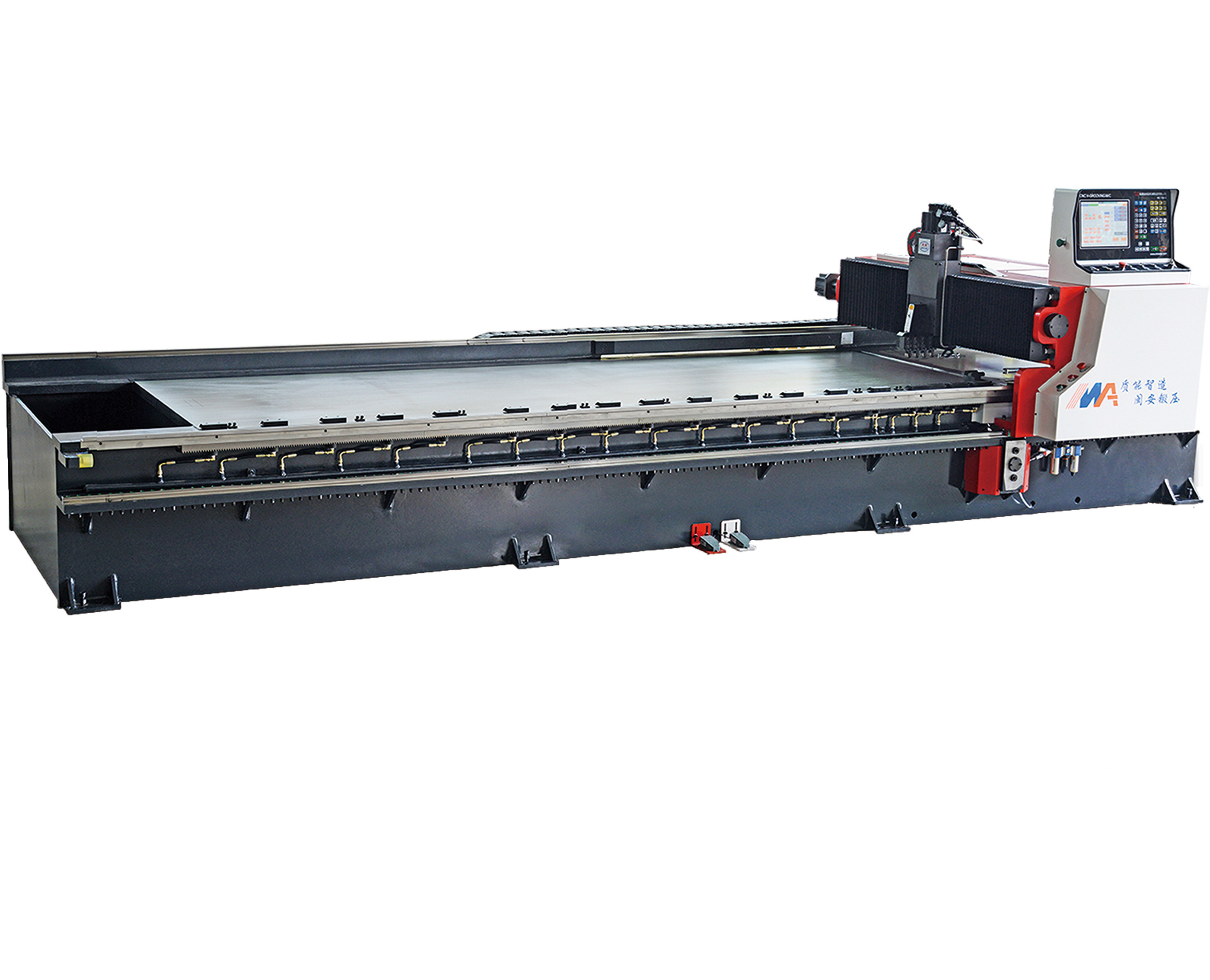

- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

5500x2750x2250

-

Weight (KG):

-

11000

-

Power (kW):

-

4.5

Quick Details

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

MINAN

-

Voltage:

-

380V/220V/415V

-

Dimension(L*W*H):

-

5500x2750x2250

-

Weight (KG):

-

11000

-

Power (kW):

-

4.5

Products Description

At present, grooving machines are mainly used for horizontal and vertical grooving of thin plates. In the industry, grooving is not only required for regular square plates, but also for irregular shaped plates that require grooving. The CNC high-speed vertical grooving machine for irregular parts can perform grooving on irregular parts and thin metal plates,achieving bidirectional grooving. The grooving efficiency is high, and it is mainly used for metal plate grooving and marking operations in various industries, especially in the metal material decoration industry of mid to high-end buildings.

Details Images

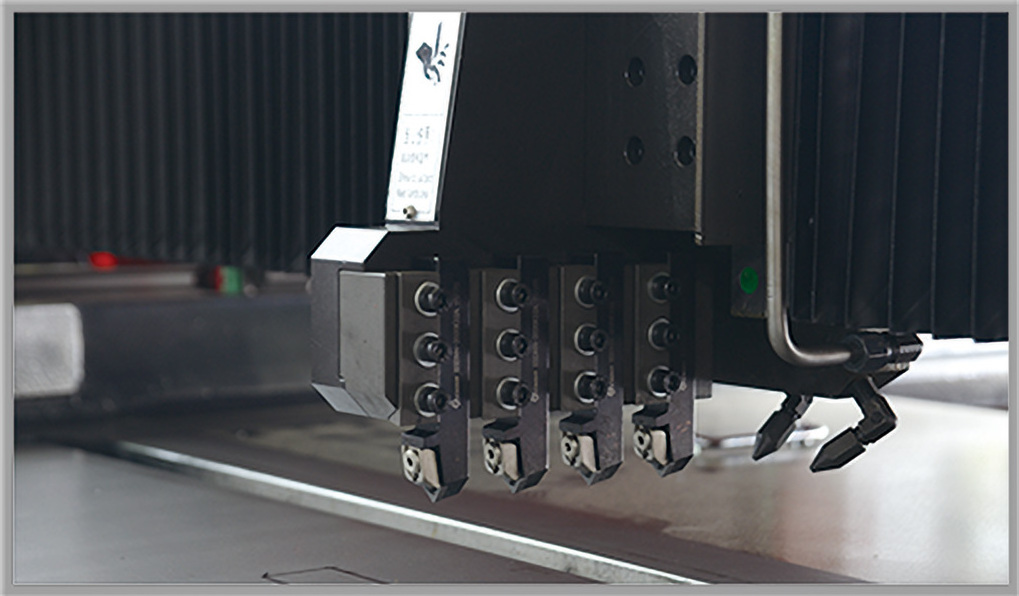

Our Advantages

The utility model has the advantages of stability, firmness and convenient use; Suitable for grooving special-shaped parts;

The control system has man-machine interface operation, multi-parameter selection, large memory capacity and convenient operation;

The number of control axes is 4 axes, and all 4 axes are AC servomotor systems with high control accura- cy;

With 8-knife cutting structure, two kinds of grooving modes (one-way grooving and back-and-forth grooving) can be selected,which can greatly improve the working efficiency and the processing quality of the products;

The precision and durability of the machine are improved by using ball screw and heavy-duty linear guide system.

Product Paramenters

|

|

Item

|

parameter

|

|

|

|

unit

|

note

|

|||

|

|

type

|

LBKS15.0*32A

|

LBKS15.0*42A

|

LBKS15.0*52A

|

LBKS15.0*62A

|

|

|

|||

|

|

Length

|

3200

|

4200

|

5200

|

6200

|

mm

|

|

|||

|

|

Width

|

1500

|

1500

|

1500

|

1500

|

mm

|

|

|||

|

|

Thickness

|

0.6-4.5

|

0.6-4.5

|

0.6-4.5

|

0.6-4.5

|

mm

|

Stainess steel

|

|||

|

X-axis

|

Max.stroke

|

3200

|

4200

|

5200

|

6200

|

mm

|

|

|||

|

|

Groove speed

|

70000

|

70000

|

70000

|

70000

|

mm/min

|

|

|||

|

|

Return speed

|

70000

|

70000

|

70000

|

70000

|

mm/min

|

|

|||

|

Y-axis

|

Max.stroke

|

15

|

15

|

15

|

15

|

mm

|

|

|||

|

|

Moving speed

|

50000

|

50000

|

50000

|

50000

|

mm/min

|

|

|||

|

Z-axis

|

Max.stroke

|

1500

|

1500

|

1500

|

1500

|

mm

|

|

|||

|

|

Moving speed

|

30000

|

30000

|

30000

|

30000

|

mm/min

|

|

|||

|

|

X-axis power

|

4.5

|

4.5

|

4.5

|

4.5

|

kW

|

|

|||

|

|

Number of control axis

|

4

|

4

|

4

|

4

|

|

X Y1 Y2 Z

|

|||

|

Overall size

|

Length

|

4500

|

5500

|

6500

|

7500

|

mm

|

|

|||

|

|

Width

|

2750

|

2750

|

2750

|

2750

|

mm

|

|

|||

|

|

Height

|

1920

|

2250

|

2500

|

2820

|

mm

|

|

|||

Recommend Products

Hot Searches