- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

GA2-1350T

-

Name:

-

aluminium extrusion machine

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

None

Quick Details

-

Place of Origin:

-

Guangdong, China, Jiangsu, China

-

Brand Name:

-

Giansun, GA

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Free spare parts, Online support, Field installation, commissioning and training, Field maintenance and repair service, Video technical support

-

Model Number:

-

GA2-1350T

-

Name:

-

aluminium extrusion machine

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

None

Aluminium Extrusion Plant

The industrial press suitable for extruding metals, such as aluminum, copper, magnesium,lead,etc

| Name | Aluminium Extrusion Plant | ||

| Extruding pressure | KN | 13500 | |

| Pressure of operation system | Mpa | 21 | |

| Return force | KN | 570 | |

| Perforation stroke | mm | 650 | |

| Extruding stroke | mm | 1400 | |

| Dia of principal plunger piston | mm | 860 | |

| Extruding speed | mm/s | 21 | |

| lngot vessel dimensions | mm | Φ135-Φ165 x 680 | |

| Piercing force | KN | 2000 | |

| Fasten strength | KN | 850 | |

| Pattern strength | KN | 1100 | |

| Shearing force | KN | 300 | |

| Motor power | KW | 55 x 4 | |

| Heating power | KW | 30 | |

| Outer dimensions (L x W x H) | M | 11.5x3.5x3.6 | |

| Height of discharging hole | mm | 1290 | |

| Weight | KG | 69000 | |

The picture of Aluminium Extrusion Plant

20 years experience Turnkey complete aluminum extrusion plant and line copper extrusion plant and line / for sale turnkey aluminium extrusion press machine aluminium extrusion machinery

I.Functions of Aluminum and copper extrusion plant

Acquire profile from aluminum,copper, magnesium and other metals

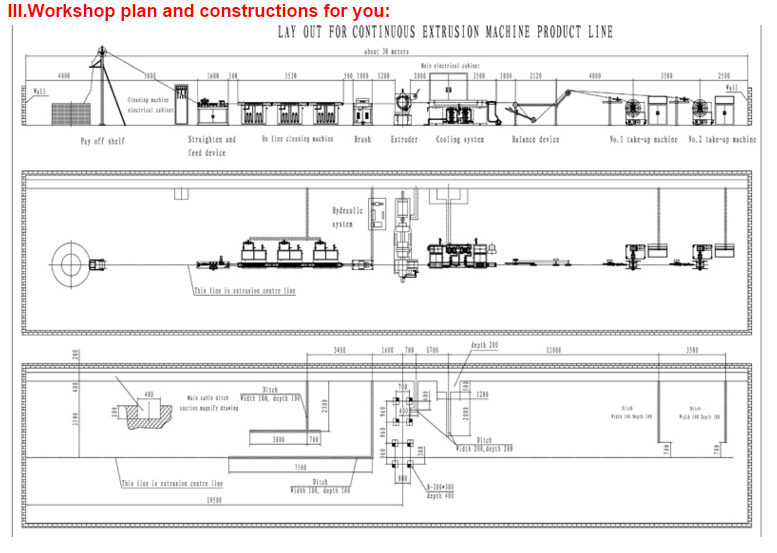

II.Work Flowchart

1.Once the desired shape for the finished profile has been developed and the appropriate aluminum alloy selected, an extrusion die, and associated tooling, is produced.

2.The actual extrusion process begins when the press ram starts applying pressure to the billet within a container. the pressure capacity of a specific press determines how large an extrusion it can produce.

3.As pressure is applied, the billet is first crushed against the die, becoming shorter and wider until its expansion is restricted by the container walls. Then, as the pressure increases, the soft (but still solid) aluminum has no place else to go and begins to squeeze out through the shaped die to emerge on the other side as a fully formed profile.

4.The formed profile is cut off at the die and the remainder of the metal is removed to be recycled. After it leaves the die, the still-hot extrusion may be quenched, mechanically treated, and aged to impart desired metallurgical properties and physical performance.

5.After sufficient aging, whether in an aging oven or at room temperature, the profiles are moved to other areas of the plant and may be finished (painted or anodized), fabricated (cut, machined, bent, welded, assembled), or packed for

shipment.

IV.Features of our extrusion Press

1.High rate of finished products

2.High production capacity

3. low breakdown rate and quick service

4.easy operation

V. All Equipments of extrusion line

1.Billet furnace with shear

Features:

a, energy saving type of backward rod pusing type heat shears

b, energy-saving heat recovery devic

c.energy -saving industrial combustion machine

d.Automatic thermal cutting machine

2.Die oven/heater,and nitriding furnace

Features:

3.Extrustion dies and toolings

Features:

5.Puller(Single/double type)

Features:

to insure the press machine to continuously extruding, do not need to consider the non-extrusion time, do not need to stop machine for profile cutting, hence able to highly improve the production efficiency and finished product rate.

In order to meat different tonnage of extrusion line, we developed “Up-Down Double Rail” and “Horizontal Double Rail” 2 kinds, which able to suit extrusion line small than 3600T and big than 3600T respectively.

6.Stretcher

Features:

Crimping pliers,Pneumatic pliers,Hydraulic pressure pliers,Manual rotatary,Electric rotary

Electric or Hydraulic rotary

7.handling table/cooling table

Features:

a. Huge synchronous belt profile handling table

b. Intelligent profile handling table

c.Hydraulic horizontal moving profile handling table

d. Chain wheel driving independently belt-changing profile handling table

8.Quntching system

Features:

a, online air / water quenching equipment

b, drenching spray air cooled joint quenching system

c, spray water-cooled cooling system

9.Aging oven.

Features:

a. Twelve basket length single door aging furnace

b. Nine basket double door aging furnace

c. Six basket double door aging furnace

d. Six basket single door aging furnace

VI.Company View:

VII.More Prodcuts: