- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

0.7T

-

Product name:

-

vertical mini biomass wood fired steam boiler

-

Design fuel:

-

Biomass Fuel

-

Application:

-

industrial

-

Color:

-

Customer's Requirement

-

Material:

-

boiler steel

-

Thermal efficiency:

-

87%

-

Rated working pressure:

-

0.7Mpa

-

Rated steam temperature:

-

170

-

Rated evaporation:

-

300kg

-

Certification:

-

ISO9001

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

SWET

-

Dimension(L*W*H):

-

1650x900x1900mm

-

Weight:

-

0.7T

-

Product name:

-

vertical mini biomass wood fired steam boiler

-

Design fuel:

-

Biomass Fuel

-

Application:

-

industrial

-

Color:

-

Customer's Requirement

-

Material:

-

boiler steel

-

Thermal efficiency:

-

87%

-

Rated working pressure:

-

0.7Mpa

-

Rated steam temperature:

-

170

-

Rated evaporation:

-

300kg

-

Certification:

-

ISO9001

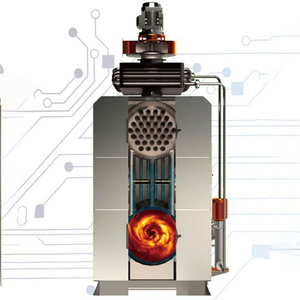

Fully automatic vertical mini biomass wood fired steam boiler for greenhouse

1.The boiler has strong adaptability to load. The well-designed built-in steam separator device meets the requirements of users for higher quality steam. The furnace body facilitates the cleaning of the inside of the furnace, which makes maintenance and maintenance extremely convenient.

2.The boiler safety is equipped with multi-level interlock protection: pressure switch protection (automatic shutdown and alarm above set pressure), low water level protection (water level in boiler body is lower than warning water level, automatic power off and alarm), safety valve protection (boiler) The pressure exceeds the working pressure, and the air pressure is automatically reduced.) Ensure that the boiler is safe under all working conditions and safe to get home.

vertical mini biomass wood fired steam boiler

core advantages:

1. Rapid steam generation in five minutes, the thermal efficiency can reach more than 90% , the pressure is stable, and the running cost is low.

2 . Low noise, low concentration of smoke and dust, no black smoke, fully in line with national first-class regional emission standards, environmentally friendly and reliable

3. Fully automatic control system with automatic high and low water level protection, saving manpower.

The

vertical mini biomass wood fired steam boiler

production process:

vertical mini biomass wood fired steam boiler

technical parameters:

|

Fuel Cost analysis(Take 100 kg per hour as an example) |

||||

|

Equipment selection |

Steam volume |

Energy consumption |

Unit Price |

Operating costs |

|

Electrothermal steam boiler |

100kg |

72 kw/h |

0.08 USD/kw |

10.91 USD |

|

Fuel steam boiler |

100kg |

7 kg/h |

0.53 USD/kg |

7.42 USD |

|

Gas steam boiler |

100kg |

8 m³/h natural gas |

0.34 USD/m³ |

5.45 USD |

|

Biomass steam boiler |

100kg |

20 kg/h wood pellet |

0.08 USD/kg |

3.03 USD |

vertical mini biomass wood fired steam boilertechnical |

|||||||||||||

|

Rated evaporation |

Rated pressure |

Rated steam tempe rature |

Feed water temper ature |

Design thermal efficiency |

Water capacity |

Steam outlet |

water intake |

Drain valve |

Dimensions |

Shipping weight |

Full load biomass consumption |

||

|

L |

W |

H |

|||||||||||

|

Kg/h |

Mpa |

℃ |

℃ |

% |

L |

DN |

DN |

DN |

mm |

mm |

mm |

T |

Kg/h |

|

300 |

0.7 |

170℃ |

20℃ |

87% |

28 |

25 |

15 |

25 |

2000 |

1400 |

2700 |

1.35 |

49.3 |

|

500 |

0.7 |

170℃ |

20℃ |

93% |

29 |

32 |

15 |

25 |

2500 |

1800 |

2500 |

4.1 |

76.8 |

|

1000 |

0.7 |

170℃ |

20℃ |

92% |

29 |

32 |

15 |

25 |

3000 |

2300 |

2500 |

6 |

153.5 |

The vertical mini biomass wood fired steam boiler

application area:

A pplication field description:

1.For food industry: food factory, beverage factory, bakery, high temperature milk sterilization, steamed soy milk, steamed steamed buns.

2.For pharmaceutical industry: hospital disinfection, hospital canteen, hospital bath, pharmaceutical equipment heating, cooking medicine.

3.For biological equipment industry: sterilizer, school laboratory, thermal test

our engineering case: