- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

YUXI baler machine

-

Weight:

-

30 KG

-

Dimension(L*W*H):

-

1100*1000*3050mm baler machine

-

Certification:

-

CE,ISO

Quick Details

-

Voltage:

-

380V, also can make 220V according your requirment

-

Power:

-

7.5KW, 7.5kw

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

YUXI baler machine

-

Weight:

-

30 KG

-

Dimension(L*W*H):

-

1100*1000*3050mm baler machine

-

Certification:

-

CE,ISO

Waste carton baler machine waste plastic bottle Hydraulic Press Vertical Cardboard Compactor Press Machine baler machine

♣ Mainly Production

♣ 1. Plastic Baler Machine ;

♣ 2. Used-clothing baler machine ;

♣ 3. Used clothes and textile compress baler machine;

♣ 4. Waste paper, metal baler machine

♣ Introduction

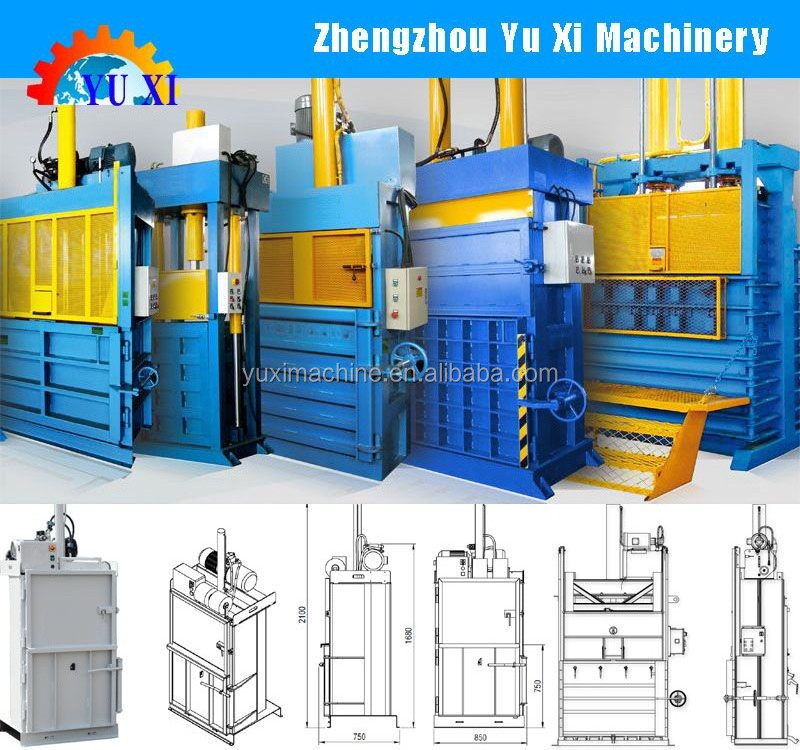

My company developed into a complete production line of Model YX-120 baler machine (mainly used to bale waster paper, newspapers.plastic, PET bottle, straw, grass, metal, etc), the device structure is novel, unique, compact, small power consumption, stable performance, Automatic feeding, automatic packaging! Usually, the pressure force of this series is from 100 KN to 600KN, (10T, 30T, 60T), the efficiency is 0.32 ~ 1T per hour. The weight of each piece is from 80 Kg to 400 Kg according to the material. Also, we can produce the machine according to the requirement of the customer.

♣ Application

♥. 1.Waste paper(include cardboard,cartons,etc)

♥. 2.Plastic( include Mineral water bottles, drinks bottles, etc)

♥. 3.Straw(include corn stover,cotton,etc)

♥. 4.Clothes waste(include burr of clothes, etc)

♥. 5.Woven bags(include rice bags,flour bags,etc)

♥. 6.Metal(Paint bucket,iron sheet,scrap iron,cans,etc)

♣ The bales have larger density and uniform size, suitable for containerized transportation, These balers can reduce storage space for wastes, saving up to 80% of stacking space; reducing transportation costs, while conducive to environmental protection and waste recycling.

♣ The industrial vertical baling machine is packing machinery connected by straps with the melting of thermal effects or covered button and other materials. The role of the equipment is to make plastic tape tied close to the surface of the strapping packages, ensuring that packages are not scattered during transport and storage, while the bundling is also neat and tidy.

♣

Main structure of press balers/baling machine/bundling machine:

The machine can be divided into five parts:

♣ 1)-The host frame system parts:

High quality thick steel plate , with Gas shielded welding sturdy frame , advanced mechanical design makes the device durable.

♣ 2)- Conveying system:

High-quality thick beam frame, high-strength steel conveyor belt style.

♣ 3)-Hydraulic system:

Hydraulic pumps, solenoid valves, and hydraulic cylinder seals and other key parts imported components, making packing pressure, low-speed block, durable, small noise.

♣ 4)-Electronic control system:

Adopt siemens motor, original PLC programmable controller. Other buttons, sensors, infrared shooting, remote control systems, and other key parts imported components, simple operation, easy maintenance.

♣ 5)-Security Alarm System:

Program control is automatically locked down five security alarm equipment malfunction in the power supply phase, power procedural errors, pressure high, people mistakenly packaged mouth, all can automatic shutdown and alarm.

♣

Characteristics

♥. 1)High package volume, high package density.

♥ . 2)PLC control, touch screen(Synchronized actions, operating instructions all will show in the screen, the size of the finished bag can be set up)

♥. 3) Automatically assigned four directions pressure.

♥. 4)Automatic Strapping(High bundled speed, high packing density)

♥. 5) There has a shear knife in the feeding mouth(can cut the large cardboard box, easy packing)

♥ . 6) Hydraulic circuit design, the failure rate is particularly low.

♥. 7) Installation is very easy, no need foundation.

♥. 8) The host framework is thicker steel, Gas shielded welding tectonics framework, the lifetime more durable!

♣

Advantages

♥. 1. This machine adopts hydraulic transmission, with an independent power sector and electrical systems.

♥. 2.Left, right, top three directions floating type shrink mouth design, be helpful for automatic pressure distribution all around, and can be widely used in different materials of packing.

♥. 3. Perfect after-sale service system, the 12 months warranty, free replacement parts, lifelong supply the parts in duty.

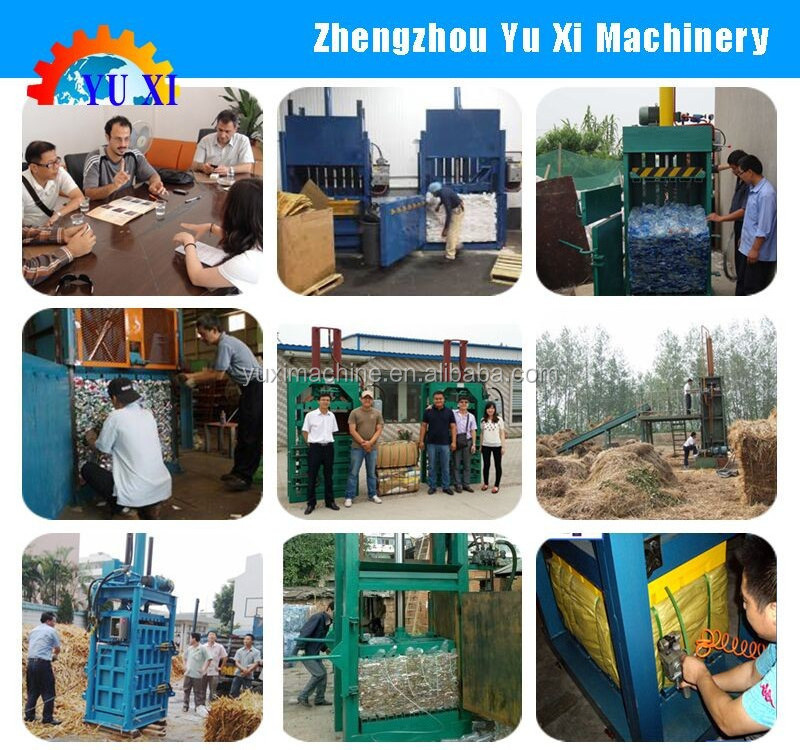

♥. 4. Specializing in balers manufacturing and exporting for more than sixteen years, with skillful workers, professional engineers, and mature sales network.

♥. 5. In our business, credibility and reputation is the most important asset we have got.

♣

Vertical Baler Advantages

♠

The vertical baling press has the advantages of easy installation, small covering area, durable, reasonable price, stable and reliable performance, and easy maintenance.

♠

It is equipped with safety interlocks and a PLC control system, which is safe to use and easy to operate.

♠

Matched oil pumps and hydraulic valves are specified pump valves for vertical cardboard baler, automatically regulating pressure and speed.

♠

. Hydraulic compaction, manual loading, manual button to operate;

♠

.

Fully maintain the physical properties of materials;

♠

. Waste compaction ratio can be up to 5: 1;

♠

. Two binding channels, easy to operate;

♠

. Anti-rebound barbs keep compress effects.

♠

. The pressure plate can be automatic homing.

♣ Our main purpose:

We Provide complete service equipment installation, testing, maintenance, and staff training, we can provide you the technical services for life and provide the best service to you. Help our clients gain profit quickly. We will provide the most environment-friendly and safe products with high quality at the most favorable price for the customer with perfect after service.

♣. Our Sweet Service:

♥. Pre-sale service : design and manufacture machines for you as your special requirements, provide you with the project, process design, and the purchase program.

♥ . On-sale service: accompany with you to look around our factory, explain the manufacturing process of our machines, and check the working performance of our machines.

♥. After-sale service : engineers are available to install and debugging equipment of the whole production line, besides, commissioning and training operators on site.

Our machine popular selling all around the world: I will provide you the best service within 24 hours!