- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

CJ

-

Weight:

-

2000 KG

-

Dimension(L*W*H):

-

4060*1040*2047mm

-

Product name:

-

Automatic tubing machine

-

Working voltage:

-

380V 50-60Hz

-

Working air pressure:

-

0.5-0.8MPa

-

Air consumption:

-

10L/min

-

Tube diameter:

-

12.7mm-60mm

-

Tube length:

-

Please see the details page

-

Max speed:

-

30meters/min

-

Delivery date:

-

60days

-

MOQ:

-

1 PCS

Quick Details

-

Voltage:

-

380V 50-60Hz

-

Power:

-

30KW, 30kw

-

Place of Origin:

-

China

-

Brand Name:

-

CJ

-

Weight:

-

2000 KG

-

Dimension(L*W*H):

-

4060*1040*2047mm

-

Product name:

-

Automatic tubing machine

-

Working voltage:

-

380V 50-60Hz

-

Working air pressure:

-

0.5-0.8MPa

-

Air consumption:

-

10L/min

-

Tube diameter:

-

12.7mm-60mm

-

Tube length:

-

Please see the details page

-

Max speed:

-

30meters/min

-

Delivery date:

-

60days

-

MOQ:

-

1 PCS

Product Overview

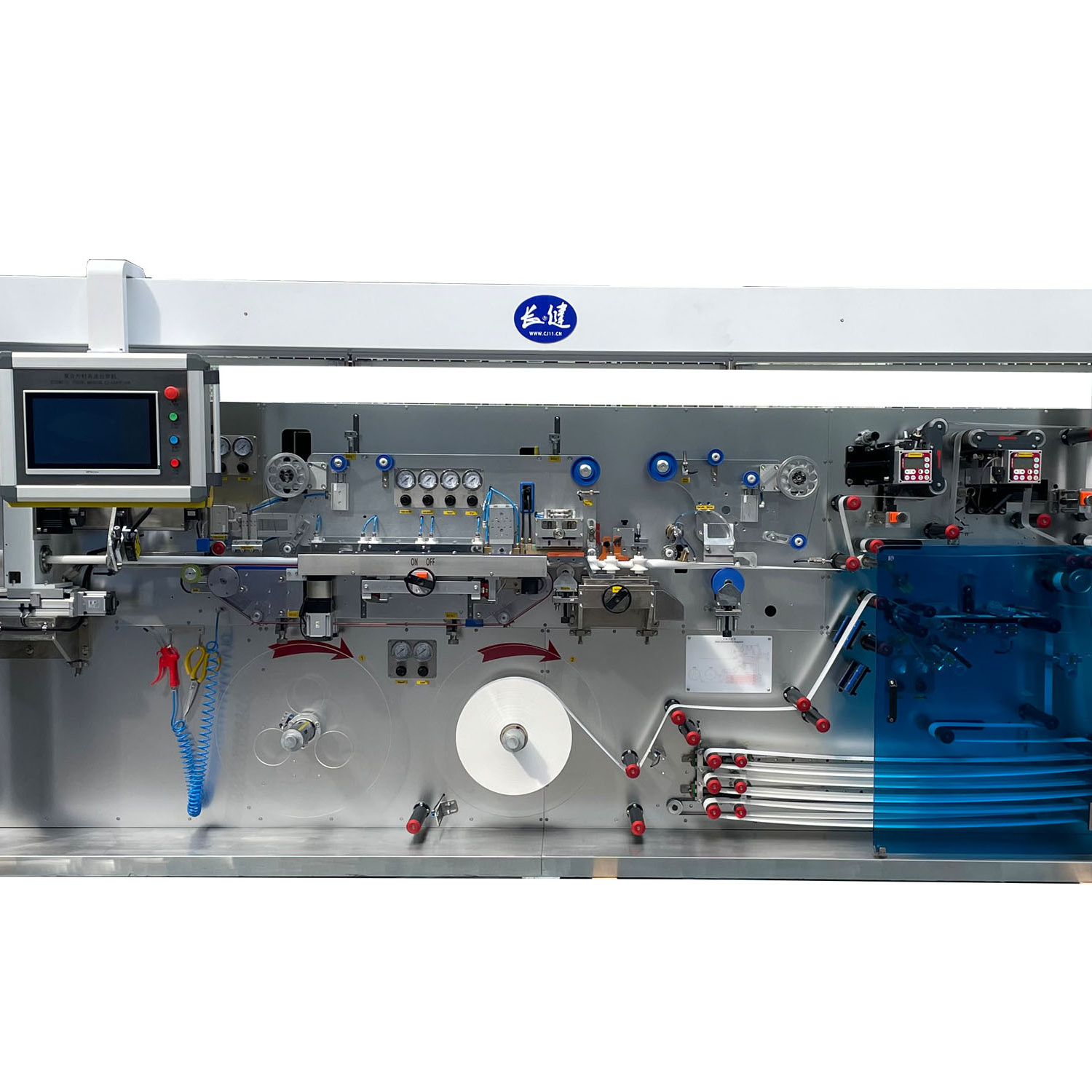

Automatic tubing machine CJ-LGA/P-100

Automatic tubing machine is designed for welding ABL and PBL web thickness range 180µm-400µm and cutting into tube body.

Our machine is design with two unwind station with the latest tension control to achieve maximum roll Dia60 to minimum roll Dia12.7 to maintain set tension. Two German-made BST web controllers deliver less than 0.1mm variations in the overlap. The machine is designed with web saver technology like side trimming and without side trim technology.

We have state of the art online web joints detection technology using Japanese made colour laser sensor to detect any unwanted particles and maintain proper inspections which help in auto rejecting.

We have designed a special body welding mandrel which maintains correct overlaps as per set value. Mandrel cooling water temperatures are controlled by an inbuilt MTC with a high-pressure water pump to maintain linear water flow and proper cooling.

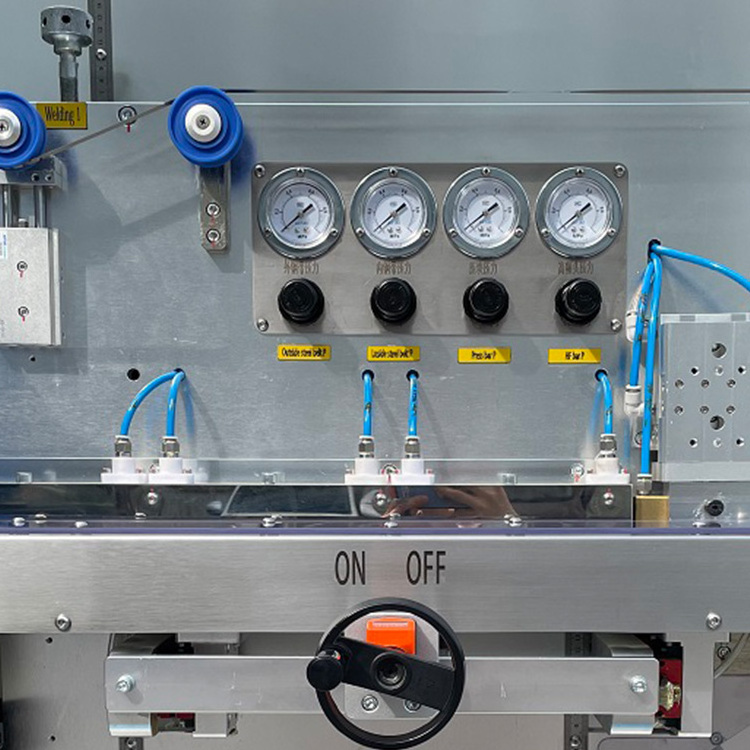

Top and bottom High-frequency induction generator with digital control and servo control metal belts to achieve higher compression and perfect welding for ABL/PBL.

Our machine is equipped with servo cutting devices for sleeves, using German-made colour sensor to detect eye mark.

The machine is fully equipped with auto rejection technology, any stop, start rejection, and web joints rejection. Printing defeat detection camera technology system is optional as per customer requirement.

Our machine is design with two unwind station with the latest tension control to achieve maximum roll Dia60 to minimum roll Dia12.7 to maintain set tension. Two German-made BST web controllers deliver less than 0.1mm variations in the overlap. The machine is designed with web saver technology like side trimming and without side trim technology.

We have state of the art online web joints detection technology using Japanese made colour laser sensor to detect any unwanted particles and maintain proper inspections which help in auto rejecting.

We have designed a special body welding mandrel which maintains correct overlaps as per set value. Mandrel cooling water temperatures are controlled by an inbuilt MTC with a high-pressure water pump to maintain linear water flow and proper cooling.

Top and bottom High-frequency induction generator with digital control and servo control metal belts to achieve higher compression and perfect welding for ABL/PBL.

Our machine is equipped with servo cutting devices for sleeves, using German-made colour sensor to detect eye mark.

The machine is fully equipped with auto rejection technology, any stop, start rejection, and web joints rejection. Printing defeat detection camera technology system is optional as per customer requirement.

PRODUCT SPECIFICATIONS

|

No

|

Item

|

Data

|

|

1

|

Model

|

CJ-LGA/P-100

|

|

2

|

Working voltage

|

380V 50-60Hz,can be customized

|

|

3

|

Working air pressure

|

0.5-0.8MPa

|

|

4

|

Power

|

30kw

|

|

5

|

Air consumption

|

10L/min

|

|

6

|

Tube diameter

|

12.7mm-60mm

|

|

7

|

Material thickness

|

170-400micro

|

|

8

|

Max speed

|

30meters/min

|

|

9

|

Cutting type

|

Circle

|

|

10

|

Dimension(L*W*H)

|

4060×1040×2047mm

|

|

11

|

Weight

|

Around 2000kg

|

|

12

|

Package

|

Wooden case

|

|

13

|

Servo motor

|

Panasonic-Japan

|

|

14

|

PLC

|

MITSUBISHI-Japan

|

|

15

|

Touch screen

|

WECON-Taiwan

|

|

16

|

Cylinder

|

AirTAC-Taiwan

|

|

17

|

Sensor

|

Panasonic -Japan

|

Hot Searches