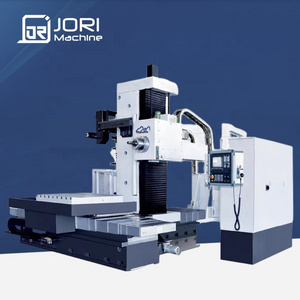

The HMC630P Horizontal Milling Machine is a versatile and high-performance machine tool used in various industries for efficient and precise milling operations.

Advantages:

1. High Precision: The HMC630P offers exceptional precision and accuracy, ensuring tight tolerances and superior surface finishes for machined parts.

2. Rigidity and Stability: With its robust construction and rigid bed, the HMC630P provides excellent stability during heavy cutting operations, minimizing vibrations and ensuring consistent results.

3. Versatility: This milling machine features multi-axis capabilities, allowing for complex machining tasks and accommodating a wide range of workpiece sizes and geometries.

4. High Productivity: Equipped with a powerful spindle and a fast tool change system, the HMC630P enables efficient and rapid production, reducing cycle times and maximizing productivity.

5. Advanced Control System: The machine incorporates a user-friendly control interface, facilitating easy programming, operation, and monitoring of milling processes.

Applications:

The HMC630P Horizontal Milling Machine finds applications in various industries, including:

1. Automotive: It is used for milling engine blocks, transmission components, chassis parts, and other automotive components.

2. Aerospace: The HMC630P is employed to machine complex aerospace parts, such as aircraft structural components, landing gear parts, and turbine components.

3. Mold and Die Making: It is widely utilized for milling molds and dies used in plastic injection molding, die casting, and other molding processes.

4. General Machining: The HMC630P caters to a wide range of general milling applications, including milling, drilling, tapping, and contouring operations on various materials.

- Product Details

- {{item.text}}

Quick Details

-

Max. Spindle Speed (r.p.m):

-

2000 r.p.m

-

Spindle Bore(mm):

-

300

-

Width of bed (mm):

-

450 mm

-

Spindle Motor Power(kW):

-

15/18.5

-

Travel (X Axis)(mm):

-

300 mm

-

Travel (Z Axis)(mm):

-

450 mm

-

Place of Origin:

-

Zhejiang, China

-

Dimension(L*W*H):

-

6485*3865*3300

-

Brand Name:

-

OEM

-

Model Number:

-

HMC63

-

Voltage:

-

-

-

Weight (KG):

-

2000

-

Marketing Type:

-

New Product 2023

-

Worktable size:

-

630*700

-

Max. load bearing of worktable:

-

1200kg

-

Number of worktable:

-

1

-

Clamping way of workpiece:

-

24*M16

-

X axis travel:

-

1050

-

Y axis travel:

-

750

-

Z axis travel:

-

900

-

L*W*H:

-

4950*3800*2980

Quick Details

-

Type:

-

Horizontal

-

Max. Length of Workpiece (mm):

-

600

-

Year:

-

2023

-

Max. Spindle Speed (r.p.m):

-

2000 r.p.m

-

Spindle Bore(mm):

-

300

-

Width of bed (mm):

-

450 mm

-

Spindle Motor Power(kW):

-

15/18.5

-

Travel (X Axis)(mm):

-

300 mm

-

Travel (Z Axis)(mm):

-

450 mm

-

Place of Origin:

-

Zhejiang, China

-

Dimension(L*W*H):

-

6485*3865*3300

-

Brand Name:

-

OEM

-

Model Number:

-

HMC63

-

Voltage:

-

-

-

Weight (KG):

-

2000

-

Marketing Type:

-

New Product 2023

-

Worktable size:

-

630*700

-

Max. load bearing of worktable:

-

1200kg

-

Number of worktable:

-

1

-

Clamping way of workpiece:

-

24*M16

-

X axis travel:

-

1050

-

Y axis travel:

-

750

-

Z axis travel:

-

900

-

L*W*H:

-

4950*3800*2980

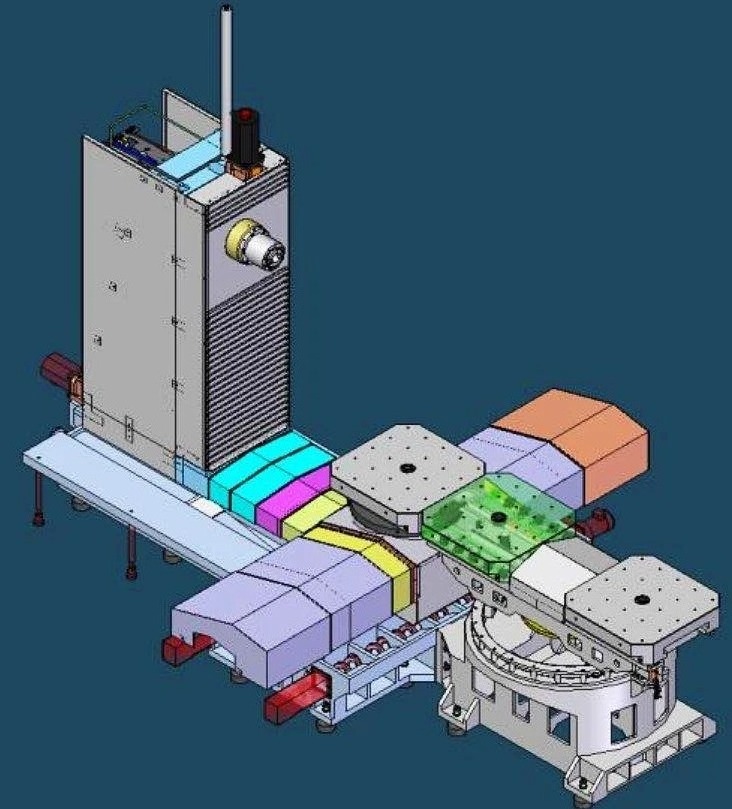

Products Description

HMC630 horizontal machining center

|

|

|

HMC63

|

HMC500

|

HMC500P

|

HMC630

|

HMC630P

|

||||||

|

Workbench

|

|

Single pallet

|

Single pallet

|

Dounle pallets

|

Single pallet

|

Dounle pallets

|

||||||

|

Workbench size

|

mm

|

630x630

|

500×600

|

500×600

|

630x700

|

630x700

|

||||||

|

The maximum load-bearing capacity of the workbench

|

kg

|

1200

|

600

|

600

|

950

|

950

|

||||||

|

Number of workbenches

|

|

1

|

1

|

2

|

1

|

2

|

||||||

|

Table form

|

mm

|

24xM16 threaded hole

|

24xM16 threaded hole

|

24xM16 threaded hole

|

24xM16 threaded hole

|

24xM16 threaded hole

|

||||||

|

Distance from the centerline of the spindle to the workbench

|

mm

|

100 ~ 1000

|

120 ~ 870

|

0 ~ 750

|

120 ~ 870

|

0 ~ 750

|

||||||

|

Distance from workbench center to spindle end face

|

mm

|

50 ~ 1080

|

130 ~ 1030

|

130 ~ 1030

|

130 ~ 1030

|

130 ~ 1030

|

||||||

|

Workpiece rotation diameter

|

mm

|

Φ1050

|

Φ1380

|

Φ950

|

Φ1380

|

Φ950

|

||||||

|

Workbench indexing

|

|

1° x360

|

1° x360 / 0.001°

|

1° x360 / 0.001°

|

1° x360 / 0.001°

|

1° x360 / 0.001°

|

||||||

|

Type of platform replacement structure

|

|

/

|

/

|

turn type

|

/

|

turn type

|

||||||

|

Workbench exchange time

|

s

|

/

|

/

|

35

|

/

|

35

|

||||||

|

3-Axis

|

|

|

|

|

|

|

||||||

|

stroke

|

mm

|

1050/900/1030

|

1050/750/900

|

1050/750/900

|

1050/750/900

|

1050/750/900

|

||||||

|

Fast Moving Distance (XNY2)

|

m/min

|

60/60/60

|

30/30/30

|

30/30/30

|

30/30/30

|

30/30/30

|

||||||

|

B-axis fast movement speed

|

m/min

|

11

|

10

|

10

|

10

|

10

|

||||||

|

Main spindle

|

|

|

|

|

|

|

||||||

|

Main spindle power (basic configuration)

|

kw

|

18.5-26

|

15/18.5

|

15/18.5

|

15/18.5

|

15/18.5

|

||||||

|

Maximum speed (basic configuration)

|

rpm

|

8000

|

6000

|

6000

|

6000

|

6000

|

||||||

|

Spindle hole thrust

|

|

BT50

|

BT50

|

BT50

|

BT50

|

BT50

|

||||||

|

Main spindle inner diameter

|

mm

|

100

|

100

|

100

|

100

|

100

|

||||||

|

Positioning accuracy (national standard

|

|

|

|

|

|

|

||||||

|

positioning accuracy

|

mm

|

0.01 (entire process)

|

0.01 (entire process)

|

0.01 (entire process)

|

0.01 (entire process)

|

0.01 (entire process)

|

||||||

|

Repetitive positioning accuracy

|

mm

|

0.006

|

0.006

|

0.006

|

0.006

|

0.006

|

||||||

|

B-axis indexing accuracy

|

|

6″

|

10″

|

10″

|

10″

|

10″

|

||||||

|

B-axis repeated indexing accuracy

|

|

1″

|

5″

|

5″

|

5″

|

5″

|

||||||

|

Tool magazine

|

|

|

|

|

|

|

||||||

|

Tool magazine capacity

|

T

|

40

|

24

|

24

|

24

|

24

|

||||||

|

Tool selection method

|

|

Two-way arbitrary

|

|

|

|

|

||||||

|

Tool change time

|

s

|

2.5

|

4.5

|

4.5

|

4.5

|

4.5

|

||||||

|

External dimensions

|

|

|

|

|

|

|

||||||

|

Length * width * height

|

mm

|

6485x3865x3300

|

4800×3700×2850

|

6600×4300×2850

|

4800×3700×2800

|

6600×4300×2850

|

||||||

|

Machine weight

|

kg

|

18200

|

11000

|

13000

|

12000

|

14000

|

||||||

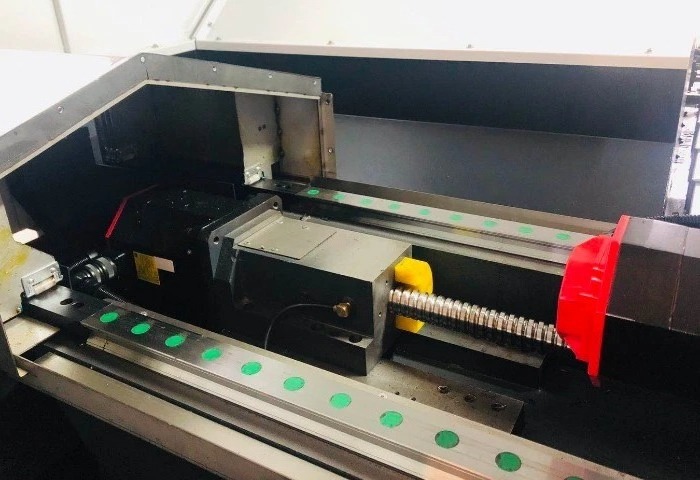

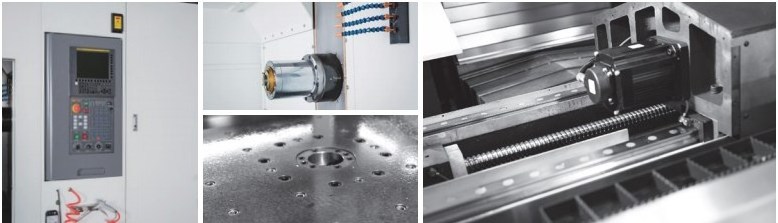

Machine Structure:

---X, Y, Z three-axis adopts ultra-wide guide rails, which have excellent rigidity, vibration absorption (suppressing vibration

generated when cutting tools) and damping (preventing vibration when the guide system is started or stopped)

---Suitable for machine tools with heavy cutting loading

---Y axes are supported by 4 guide rails, which has stronger carrying capacity. X and Y axis are linear guideway. Z axis is box /linear guideway.

generated when cutting tools) and damping (preventing vibration when the guide system is started or stopped)

---Suitable for machine tools with heavy cutting loading

---Y axes are supported by 4 guide rails, which has stronger carrying capacity. X and Y axis are linear guideway. Z axis is box /linear guideway.

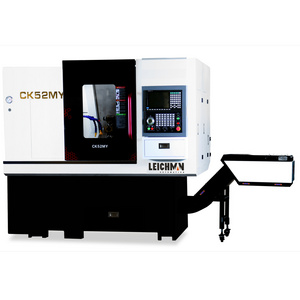

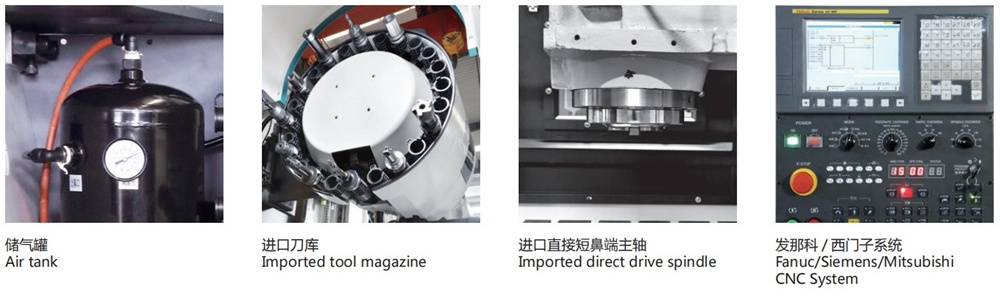

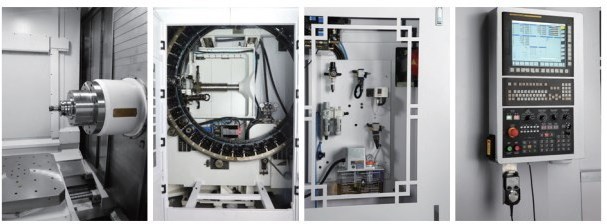

Spindle :

Taiwan brand short nose BT50-190mm spindle, standard is belt drive 8000rpm.

15/18.5Kw large power motor with high torque 143Nm

Ultralight spindle headstock and Z axis with counter balance block

15/18.5Kw large power motor with high torque 143Nm

Ultralight spindle headstock and Z axis with counter balance block

Manual Scrape :

Manual scraping is used on the main joint surface to ensure effective contact area

Axes Driving :

---The 3 axes servo motors are directly connected to the high-precision ball screw via a gapless elastic coupling to ensure transmission accuracy.

---All servo motors are equipped with absolute encoders to increase efficiency and reliability.

----The three axis screw is pre-stretched to eliminate the influence of screw temperature rise on machining accuracy

---All servo motors are equipped with absolute encoders to increase efficiency and reliability.

----The three axis screw is pre-stretched to eliminate the influence of screw temperature rise on machining accuracy

Application

Related Products

CNC machines

*CNC worm grinding machine

*CNC forming gear grinding machine

*CNC rolling cutter shovel grinding machine

*CNC cutting edge grinder

*CNC grinding wheel repair machine

*CNC shovel tooth lathe

*Fully CNC high-speed gear hobbing machine

Processing tools

*

Measuring instruments

*

Production equipment

*

Gear hob

*

Insert gear hob

*

Gear hob

*

Worm gear hob

*

Involute spline hob

*

Triangular spline hob rectangular spline hob

*

Sprocket roller cutter

*

Circular arc gear hob

*

Synchronous belt roller cutter

Hot Searches