- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

GD8020

-

Brand Name:

-

LIANGYIN

-

Delivery Time:

-

10-15 days

-

Type:

-

Aluminum Extrusions Profiles

-

Surface treatment:

-

Mill Finish,Anodized,Power coated

-

Payment term:

-

T/T, L/C

-

Color:

-

Silver,black, red, gold,customized color

-

Thickness:

-

0.7mm-customized

-

Main Market:

-

Europe, America, Southeast Asia,etc

-

Certification:

-

ISO9001:2015, COC

-

Main processing equipment:

-

extrusion, CNC, surface finishing

-

Item:

-

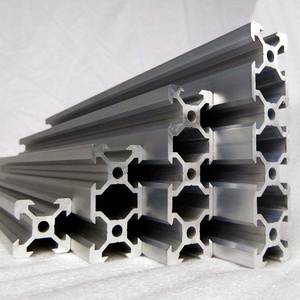

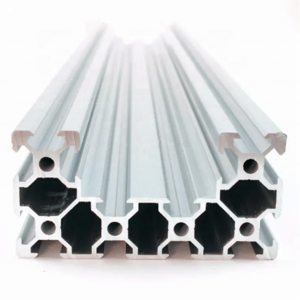

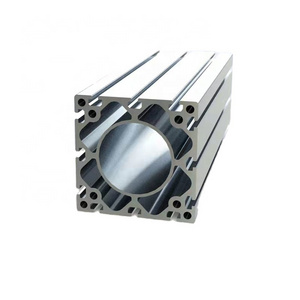

3D printer / laser engraving machine

-

Product name:

-

3D printer metal aluminum extruded profiles anodized

Quick Details

-

Grade:

-

6063 / 6061

-

Tolerance:

-

CUSTOM

-

Place of Origin:

-

Guangdong, China

-

Model Number:

-

GD8020

-

Brand Name:

-

LIANGYIN

-

Delivery Time:

-

10-15 days

-

Type:

-

Aluminum Extrusions Profiles

-

Surface treatment:

-

Mill Finish,Anodized,Power coated

-

Payment term:

-

T/T, L/C

-

Color:

-

Silver,black, red, gold,customized color

-

Thickness:

-

0.7mm-customized

-

Main Market:

-

Europe, America, Southeast Asia,etc

-

Certification:

-

ISO9001:2015, COC

-

Main processing equipment:

-

extrusion, CNC, surface finishing

-

Item:

-

3D printer / laser engraving machine

-

Product name:

-

3D printer metal aluminum extruded profiles anodized

Details Images

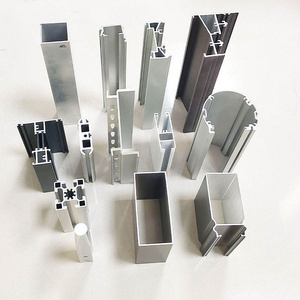

Products Description

|

SHAPE

|

square, round, shaped, rectangular, customized

|

|

APPLICATION

|

furniture, windows&door, decorations, industry, constructions, and so on

|

|

SURFACE TREATMENT

|

mill finish, anodizied, powder coating, fluorine carbon spraying, and so on

|

|

COLORS

|

silver, black, blue, wood color, RAL powder coating color and so on

|

|

DEEP PROCESS

|

CNC, drilling, milling, cutting, bending, assembling

|

|

PACKING DETAILES

|

Inside: packed with plastic protective film to protect each piece

Outside: wrap to be bundles by waterproof craft paper |

|

DELIVERY TIME

|

Mass production completed: 20-30 days after sample is comfirmed by client

|

|

FOB PORT

|

FOSHAN/SHENZHEN/GUANGZHOU

|

|

PAYMENT TERMS

|

T/T 30% for deposit, balance before shipping

|

|

PRODUCTION CAPACITY

|

5000 tons monthly, 60000 tons annualiy

|

|

CERTIFICATES

|

SGS, CE, ISO, QUOLANOD AVAILABLE

|

Material Technique

|

GRADE

|

6063

|

6061

|

6463

|

3003

|

|||

|

STANDARD

|

GB/T 3190-1996

|

|

|

|

|||

|

Al

|

Remain

|

Remain

|

Remain

|

Remain

|

|||

|

Si

|

0.2-0.6

|

0.4-0.8

|

0.2-0.6

|

<=0.6

|

|||

|

Cu

|

<=0.1

|

0.15-0.4

|

<=0.2

|

0.05-0.2

|

|||

|

Mg

|

0.45-0.9

|

0.8-1.2

|

0.45-0.9

|

/

|

|||

|

Zn

|

<=0.1

|

<=0.25

|

<=0.05

|

<=0.1

|

|||

|

Mn

|

<=0.1

|

<=0.15

|

<=0.05

|

1.0-1.5

|

|||

|

Ti

|

<=0.1

|

<=0.15

|

/

|

/

|

|||

|

V

|

/

|

/

|

/

|

/

|

|||

|

Fe

|

<=0.35

|

<=0.7

|

<=0.15

|

<=0.7

|

|||

|

Cr

|

<=0.1

|

0.04-0.35

|

/

|

/

|

|||

|

SINGLE

|

0.05

|

/

|

0.05

|

0.05

|

|||

|

TOTAL

|

0.15

|

/

|

0.15

|

0.15

|

|||

Product Series

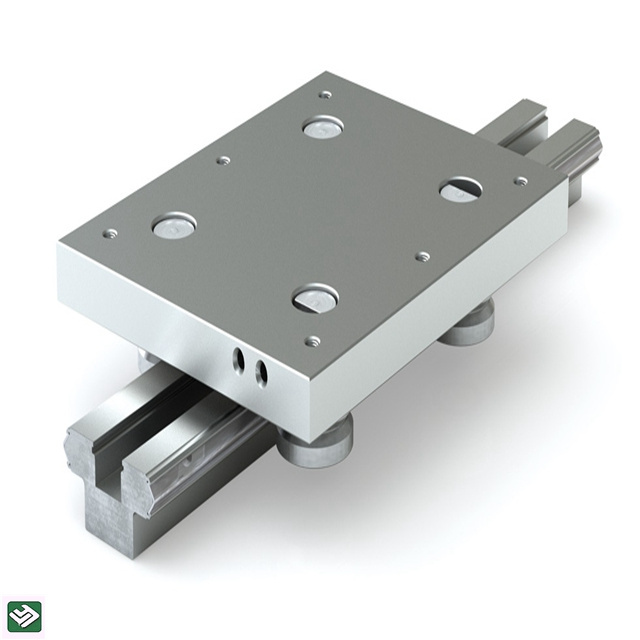

1.Aluminum Extrusion-Linear Guide

An aluminium linear guide is used to support or guide a piece of equipment through a linear path in an environment which dictates

the linear guide must have excellent corrosion resistance properties.

the linear guide must have excellent corrosion resistance properties.

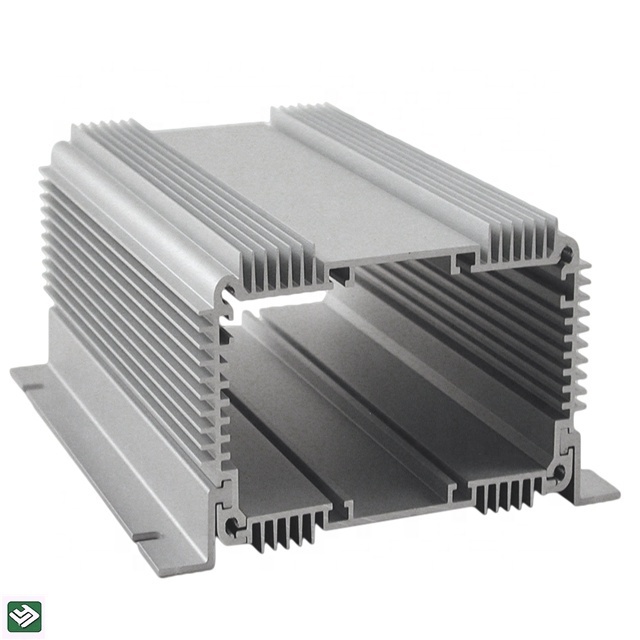

2.Aluminum Extrusion- High power ev shell

There are numerous examples of aluminum use in electric vehicles: The body-in-white plays a crucial role in vehicles, encompassing

the chassis, floor pan, and body panels. Electric cars increasingly rely on aluminum for this structure to enhance fuel efficiency

and reduce weight.

the chassis, floor pan, and body panels. Electric cars increasingly rely on aluminum for this structure to enhance fuel efficiency

and reduce weight.

Discover More About Our Customized Aluminum Products, Please Contact Our Sales Manager

Why Choose Us

Customer Photos

Recommend Products

FAQ

1.Which kind alloy profiles can your factory produce?

Q:We can produce 6061,6063, 3003, 6463.

2.Which kind of aluminum alloy is better?

Q:Should according to the usage to select workable alloy

Alloy 6063 is widely used as building aluminum windows and doors,frame of curtain wall and general accessories of industrial products.

6061 is widely used in industry equipment.

Alloy 3003 is one kind of antirust aluminum alloy most widely used. Mostly used as the parts requirement for high plasticity and good weldability.

3.Why need do anodizing process?

Q:Aluminum alloy is active metal, though can get porous oxidation film in air but not strong enough for corrosion resistance. After anodizing, there will be anodized film to get improve its corrosion resistance, abrasion resistance and decorative.

4.Does your factory produce the die-casting aluminum product?

Q:We don't produce die-casting aluminum alloy products at present. But we can cooperate with many die-casting factories in Foshan.

5.Why we need painting?

Q:Can improve the corrosion resistance, and get colorful surface by powder coating for the constructional profiles.

6.What kind products can you produce?

Q:Aluminum extrusion profiles, machining and fabricated aluminum products, such as lathe,milling,welding,riveting, bending, etc.

Hot Searches