- Product Details

- {{item.text}}

Quick Details

-

Weight (T):

-

2

-

Type:

-

Automatic

-

Application:

-

Industrial Metal Cutting

-

Cutting mode:

-

Plasma Cutting+ Flame Cutting

-

Cutting material:

-

Metal .alloy Metal .aluminum

-

Profile Steel:

-

square tube, round tube, angle iron, shelf, rectangular tube

-

Color:

-

Customized

-

Control system:

-

CNC Controller

-

Memory Function:

-

Can be stored and memorized

-

Lubrication oil:

-

Sinopec or Exxon mobil

-

Cutting thickness:

-

3-12mm

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Besco

-

Voltage:

-

220 630

-

Weight (T):

-

2

-

Type:

-

Automatic

-

Application:

-

Industrial Metal Cutting

-

Cutting mode:

-

Plasma Cutting+ Flame Cutting

-

Cutting material:

-

Metal .alloy Metal .aluminum

-

Profile Steel:

-

square tube, round tube, angle iron, shelf, rectangular tube

-

Color:

-

Customized

-

Control system:

-

CNC Controller

-

Memory Function:

-

Can be stored and memorized

-

Lubrication oil:

-

Sinopec or Exxon mobil

-

Cutting thickness:

-

3-12mm

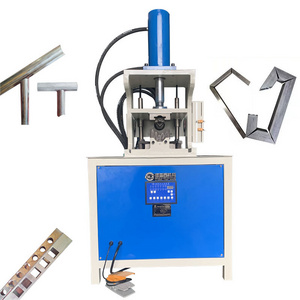

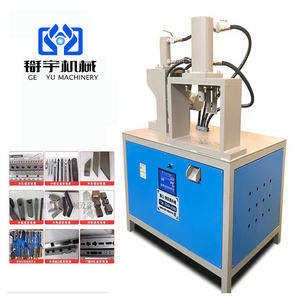

Hydraulic Round Square Pipe double line processing Punching Press Automatic CNC

Tube Hole Pipe Punching Machine

Fully automatic CNC pipe punching machine imported Servo motor automatic feeding,accurate pitch,man-machine interface,The operation is simple,is the ideal equipment for pinching zinc steel guardrail,anti-theft network,shelf industry.

Features

Punching holes are smooth and no burrs and no deformation. Half single hole punching,double hole punching,Isometric hole punching,none- Isometric hole punching,rotary punching,Hole or Completely hole are available, The hole shape can be customized as per the request.

1.Touch Screen settings, CNC control system, precise servo motor positioning, module storage memory function, equipped with hydraulic and Servo System.

2. Mould replacement: change the die easily without adjusting the dies to reduce the mould damage rate and pipe fittings rejection rate due to the dies setting error. Skillful workers can change the mould within 10 minutes.

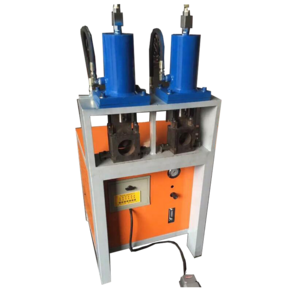

3. Step-less operation adjustment, hydraulic loops designed with zero load, combined with extremely low frequency oil pump motor, effectively reduced noise, increased motor efficiency and service duration.

4.When the oil cylinder is moving downward, the machine is designed with hydraulic difference driving loops rated at high or low RPM .it is also featured with high speed downward moving, low speed processing and hi-speed position resume .it is available to increase the formation stability of work pieces during puncturing. In addition to increasing the activation speed, it can effectively reduce HP load to save electrical energy.

5.The electrical control system is designed with the human machine interface, range adjustment use digital scale, setting low speed position, floor level position, and operation precise and easy.

Technical parameter

|

NO.

|

Item

|

Data

|

|

1

|

Size

|

Single line, Double line

|

|

2

|

Processing catagory set :

|

Single punch, not equidistant punching,

equidistant punching

rotary 360 degree

( can be customized )

|

|

3

|

Diameter and thickness of punching processing :

|

Φ 50 × t 3 --- Φ 40 × t 12mm

|

|

4

|

Processing of pipe diameter

( can be customized ) :

|

square tube : 20×20 ---120×120mm

|

|

|

|

rectangular tube : 15×30 --- 60×120mm

|

|

|

|

angle iron : 30×30 --- 120×120mm

|

|

|

|

channel iron : 25×50 --- 120×120mm

|

|

5

|

Punching hole distance :

|

0.1mm - 11900mm

|

|

6

|

Punching speed :

|

0.8-1.5 secound/ per hole, max 180mm stroke.

|

|

7

|

Maximum punching distance :

|

12000mm ( can be customized )

|

|

8

|

Standard length of processing :

|

12000mm ( can be customized )

|

|

9

|

Transmiss parts :

|

flock and pinion drive, ball screw drive

|

|

10

|

Ram pressure :

|

5T --- 60T

|

|

11

|

Punching hole method

|

Oil pressure

|

|

12

|

Power

|

380V 50HZ

|

1.The motor

2.Accurate punching control

3.Control System

8-inch display control touch screen,can store multiple sets of data , full hole, equidistant, unequal punching, etc., with many functions and simple operation.

The control system also supports Chinese, English and Russian.

4.High working efficiency

Pipe punching

Touch screen

.

|

Size

|

According to model

|

|

Weight

|

According to model

|

|

Packaging Details

|

The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request.

|

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

BESCO machinery company is professional on manufacturing mechanical power press, pneumatic power press, hydraulic power press,press brake,shearing machine,plate bendingand rolling machine, profile bending and rolling machines.

We have 30 years experience on manufacture metal working machines and we export our machines to all the worldwide market and have the best response from customers.

We can also customize the machine by requirement and offer you our best quality machine and the after sale service.

What will be the payment method?

Answer: 30% down payment and the balance should be paid before shipment.

What will be the soonest delivery time?

Answer: usuall in stock, if not, the latest delivery time is 30 days.

Answer: 30% down payment and the balance should be paid before shipment.

What will be the soonest delivery time?

Answer: usuall in stock, if not, the latest delivery time is 30 days.

Hot Searches