Our products including : Liquid filling machines (water, fruit juice/tea, carbonated drink, oil, alcohol,plant protein drink,etc.); Barrel filling line(1-5 gallon); Water treatment machines, Labeling & packing machines, Semiautomatic/Full automatic PET Bottle blowing machines, and Injection molding machines. Labeling machine, Bottle shrink packing machine , Carton packing machines ,Conveyor system , Juice processing system , Sterilizer and so on.

- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

1~3ml

-

Voltage:

-

customized

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Vpack

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

5000 KG

-

Product name:

-

Bottle Filling Capping

-

Usage:

-

Beverage Filling Packaging

-

Control:

-

PLC+ Touch Screen

-

Power:

-

Customized

-

Material:

-

SUS304/316

Quick Details

-

Machinery Capacity:

-

4000BPH, 8000BPH, 12000BPH, 6000BPH, 20000BPH, 1000BPH

-

Packaging Material:

-

Plastic, Glass

-

Filling Material:

-

Water

-

Filling Accuracy:

-

1~3ml

-

Voltage:

-

customized

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Vpack

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

5000 KG

-

Product name:

-

Bottle Filling Capping

-

Usage:

-

Beverage Filling Packaging

-

Control:

-

PLC+ Touch Screen

-

Power:

-

Customized

-

Material:

-

SUS304/316

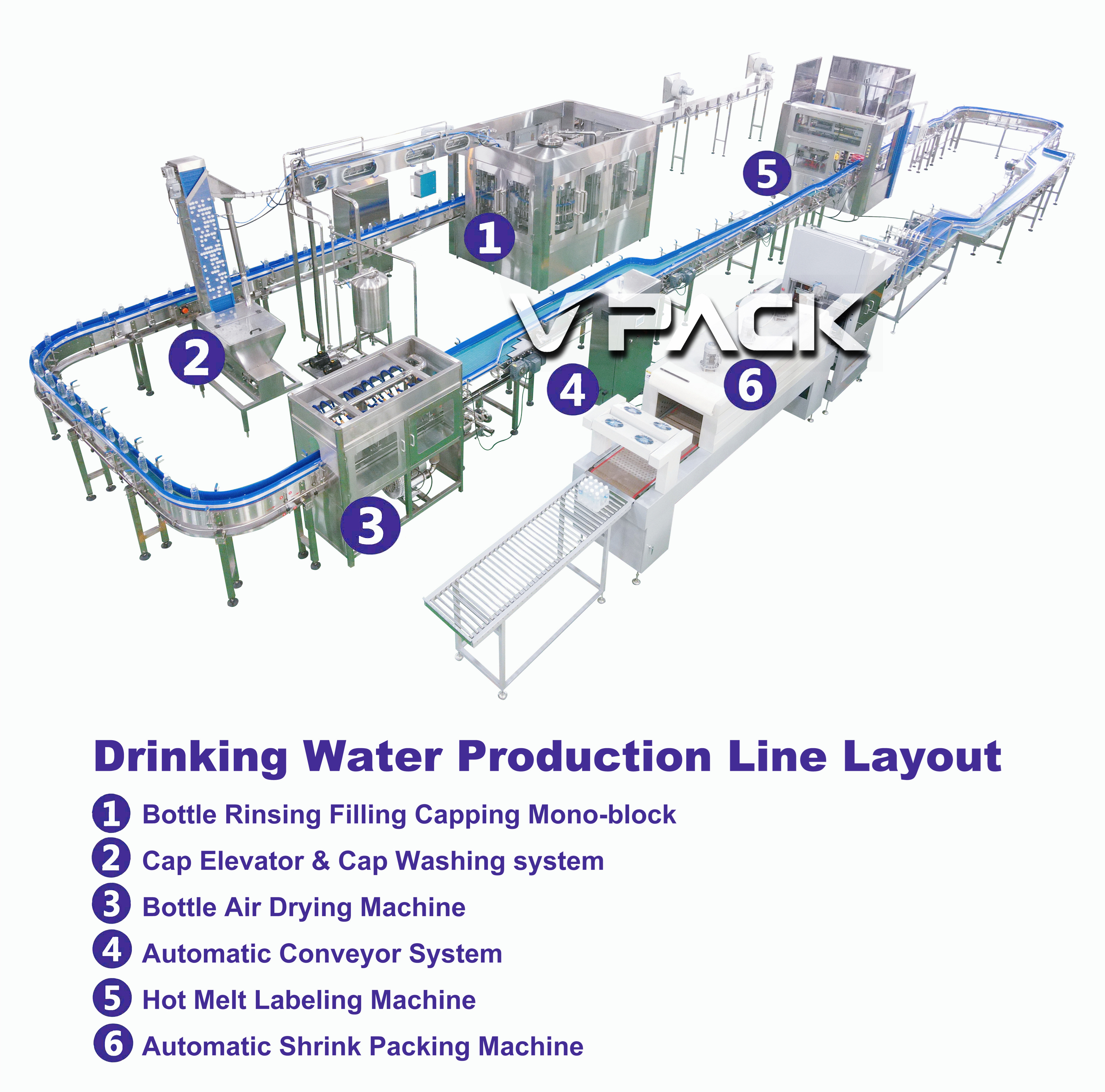

Full Set Water production Line

Product Description

Drinking Water Washing Filling Capping 3 in 1

·This Drinking Water bottle Filling machine CGF Washing-Filling-Capping 3-in-1 unit is used to produce polyester bottled mineral water, purified water, alcoholic liquid and other non-gas beverage.

·Beverage Machinery can finish all the process such as washing bottle, filling and sealing, it can reduce the materials and outsiders touch time, improve the sanitary conditions, production capacity and economic efficiency.

·The Complete Bottled Mineral Water / Pure Water Production Line used in the beverage filling operations.

·The three functions of bottle washing, filling and sealing are composed in one body of the machine.

·The whole process is automatic.

·The three functions of bottle washing, filling and sealing are composed in one body of the machine.

·The whole process is automatic.

Main Features

The machine adopts advanced

SIEMENS

programmable logic controller (PLC) to control the automatic running of the machine. The input bottle adopts air conveying device; the output bottle adopts adjustable speed way, which combines with the transducer of the host machine making the output bottle running more stable and reliable. The photoelectric inspection of the running condition of various parts makes a higher automation and convenient operation. It is the ideal first-choice equipment of beverage manufacturers.

<1> Using the wind sent access and move wheel in the bottle directly connected technology; canceled screw and conveyor chains, this enable the change the bottle-shaped become easier.

<2> Bottles transmission adopt clip bottleneck technology, bottle-shaped transform not need to adjust the equipment level, only change related the curved plate, wheel and nylon parts is enough.

<3> The specially designed stainless steel bottle washing machine clip is solid and durable, no touch with the screw location of bottle mouth to avoid secondary pollution.

<4> High-speed large gravity flow valve filling valve, filling fast, filling accurate and no liquid lose.

<5> Spiraling decline when output bottle, transform bottle shape no need to adjust the height of conveyor chains.

<6> Host adopt advanced PLC automatic control technology, the key electrical components from famous company such as Japan's Mitsubishi , France Schneider , OMRON .

<2> Bottles transmission adopt clip bottleneck technology, bottle-shaped transform not need to adjust the equipment level, only change related the curved plate, wheel and nylon parts is enough.

<3> The specially designed stainless steel bottle washing machine clip is solid and durable, no touch with the screw location of bottle mouth to avoid secondary pollution.

<4> High-speed large gravity flow valve filling valve, filling fast, filling accurate and no liquid lose.

<5> Spiraling decline when output bottle, transform bottle shape no need to adjust the height of conveyor chains.

<6> Host adopt advanced PLC automatic control technology, the key electrical components from famous company such as Japan's Mitsubishi , France Schneider , OMRON .

Product Paramenters

Detailed Images

1-

Air Conveyor.

●

Air conveyor is fixed on the floor, with fan installed on the top.

● Air filter is positioned at every entrance of air fan, to prevent dust blown into bottles.

● Bottles are held on the neck in the conveyor and transported into filling machine by blowing power.

● All are made of stainless steel SUS 304/316.

● Rack made by high quality carbon steel welded.

● Air filter is positioned at every entrance of air fan, to prevent dust blown into bottles.

● Bottles are held on the neck in the conveyor and transported into filling machine by blowing power.

● All are made of stainless steel SUS 304/316.

● Rack made by high quality carbon steel welded.

1 - Washing Parts.

●

Into bottle way is air conveyor direct connection with bottle dial.

● All 304/316 stainless steel rinser heads, water spray style inject design.

● 304/316 Stainless steel Gripper with plastic pad, ensure minimal bottle crash during wash more save water consumption & more cleaning.

● 304/316 stainless steel washing pumps.

3 - Filling Parts.

● 304/316 High precision flling nozzle, PLC variable signal control, ensure high flling precision & flling smoothly & steadily.

●

Filling volume adjustable in fine rank, same liquid level after filling.

● All 304/316 stainless steel contact parts & liquid tank,

filling pump,

fine polish, easy to clean.

●

Efficient spray nozzle rinse thoroughly and save water for flushing

● No bottle no flling.

4 - Capping Parts.

● Place & capping system, electromagnetic

capping heads, with burden discharge

function, make sure minimum bottle crash

during capping.

● AlI 304stainless steel construction.

●

Automatic stop when lack of bottle

.

● No bottle no capping.

●

Capping effect is stable and reliable, Defective rate ≤0.2%

5 - Flat Conveyor.

●

Energy saving. High efficient. Adapt to customer factory layout

● Special lubrication system, keep products clean, health, safety

● Extended service life

● Electric eyes design keep whole line running safety and quickly

● Overload protection mechanism to effectively ensure the safety of the machine

● Special lubrication system, keep products clean, health, safety

● Extended service life

● Electric eyes design keep whole line running safety and quickly

● Overload protection mechanism to effectively ensure the safety of the machine

Summary:

1. Usage: washing, filling and capping 3 in 1 mono-block is used for fling mineral water or pure water into PET

bottle. Full automatically; it can finish washing (bottle), filling and capping three jobs in the one machine.

2. Max production capacity:

See table above.

3. Material: Connection parts with liquid use SUS 304Stainless steel (I Food grade) , Made in China, Drive

structure、gear wheel A4 carbon-steel quenching.

Character:

1. The whole machine applies bottle handling technical and the filling valves go up-down when filling, which make

sure the bottle filling goes stable, reliable during high speed. The bottle handling technical also make the

different bottle change easily without changing many accessories.

2. This machine uses new generation stainless steel spring washing clips and the clips do not contact the upside

of bottle screw avoiding the second pollution. It can both clear the inside and the outside of the bottle.

3. The advanced gravity filling principle was applied. Filling is quick, and stable. Not contacting with the liquid

avoids second pollution and oxidation.

4. This machine applies magnetic force screw type sealing, realizing auto grasping cap, sealing. The sealing cap

force can be adjusted.

5. Use single electrical planet,to sure electrical apparatus element operate well

6. Automatic feed cap and by air conveying

7. The capping machine adopts a full copper structure, which is ahead of the rest of the filling machine production

plant. The structure is not easy to wear and the equipment has a longer service life.

Related products

RO water treatment system

•Stainless steel high pressure film shell

•All kinds of capacity indicator, pressure indicator, electricity magnetic valve, balance device and pipe valve system

•Online type pressure auto self-protection device

•Online type electricity indicator (with stable compensation)

•System safe protecting and alarm system

•System frame

•All kinds of capacity indicator, pressure indicator, electricity magnetic valve, balance device and pipe valve system

•Online type pressure auto self-protection device

•Online type electricity indicator (with stable compensation)

•System safe protecting and alarm system

•System frame

This packing machine is suitable for PE, PP, PET bottles.The machine occupies a small area and speed is fast. Its own conveyor

belt can be connected to the production line. The packaging size can be customized according to the actual production needs of

customers, with a certain range of adjustment, PLC control system and human-machine interface, easy to operate, and solve the

packaging problems of plastic products for customers all over the world.

Our Company

Our Service

Factory Design Service

Bottle Design Service

Pre-Sales Service

* Inquiry and consulting support.

* Machine testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Packing & Delivery

|

Sales Manager

|

Ivy Zhang

|

|

|

|

|||

|

Responsible for the project

|

CO2 & Fiber Laser Printer, Water purificaiton system, water filling machine,Juice hot filling machine ,5 gallon plant etc, Bottle blower...all kind of machine after-service.

|

|

|

|

|||

|

Responsible for the market

|

United Kingdom, Peru, Brazil, Morocco, Nigeria, Yemen etc...

|

|

|

|

|||

Hot Searches