Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Nanjing Sumino Extrusion

-

Voltage:

-

220V or 380V or customization

-

Dimension(L*W*H):

-

customization

-

Power (kW):

-

15

-

Weight:

-

2500 KG

-

Name:

-

3d printer filament extruder machine

-

Raw material:

-

ABS, ABS,PLA ,PP, PE,PC

-

Product Type:

-

3D filament extruder

-

Motor:

-

ABB

-

PLC:

-

SIEMENS

-

Control:

-

PLC+Touch Screen

-

Filament diameter:

-

1.75 mm 3.0 mm

-

Roundness Measuring:

-

X,Y Roundness Laser Device

-

Color:

-

Customer Choice

-

Roundness Laser:

-

+/- 0.03 mm

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

Other

-

Screw Speed (rpm):

-

150 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Nanjing Sumino Extrusion

-

Voltage:

-

220V or 380V or customization

-

Dimension(L*W*H):

-

customization

-

Power (kW):

-

15

-

Weight:

-

2500 KG

-

Name:

-

3d printer filament extruder machine

-

Raw material:

-

ABS, ABS,PLA ,PP, PE,PC

-

Product Type:

-

3D filament extruder

-

Motor:

-

ABB

-

PLC:

-

SIEMENS

-

Control:

-

PLC+Touch Screen

-

Filament diameter:

-

1.75 mm 3.0 mm

-

Roundness Measuring:

-

X,Y Roundness Laser Device

-

Color:

-

Customer Choice

-

Roundness Laser:

-

+/- 0.03 mm

Product Description

General Overview of 3D printing filament production line

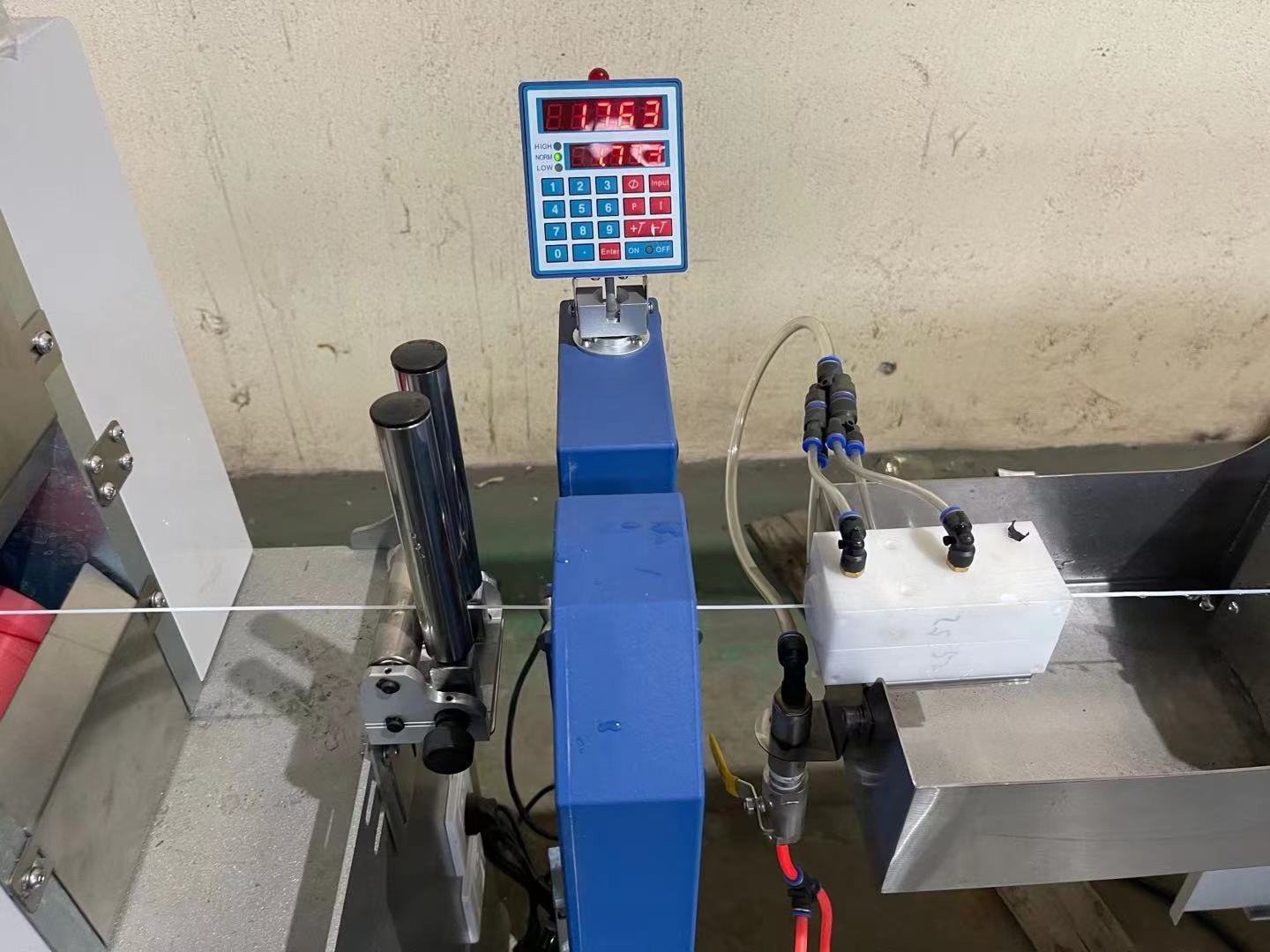

The 3D printing filament production line is composed of precision single screw extruder, wire mold, water tank cooling system,

wire storage system, traction system, caliper system, winding system and measurement and control system, etc., which can realize

wire extrusion, cooling and measurement Diameter, winding and other functions.

wire storage system, traction system, caliper system, winding system and measurement and control system, etc., which can realize

wire extrusion, cooling and measurement Diameter, winding and other functions.

Product Performance

1. High-strength European standard integrated rack, 304 stainless steel desktop, practical and beautiful.

2. High-performance servo motor, wide speed range, more stable speed.

3. Humanized structure design, more convenient operation.

4. Traction and caliper form closed loop control, which can quickly respond to changes in extrusion speed.

2. High-performance servo motor, wide speed range, more stable speed.

3. Humanized structure design, more convenient operation.

4. Traction and caliper form closed loop control, which can quickly respond to changes in extrusion speed.

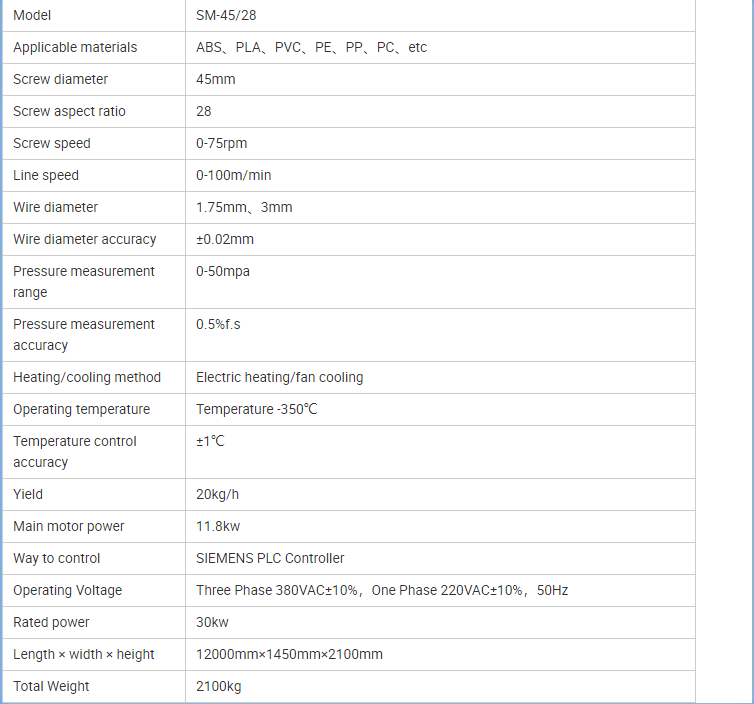

Product Paramenters

Workshop Show

Product Application

1.Extrusion performance test of polymer material wire

2.Plastic wire formula design

3.Optimization and control of process parameters of plastic wire extrusion

4.For extruding single/multi-cavity, multi-spec plastic wires

5.Process optimization, cost control and small-scale production, etc.

2.Plastic wire formula design

3.Optimization and control of process parameters of plastic wire extrusion

4.For extruding single/multi-cavity, multi-spec plastic wires

5.Process optimization, cost control and small-scale production, etc.

Hot Searches