- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V, 440V or customized

-

Power:

-

According to the equipment configuration

-

Weight:

-

3500 KG

-

Dimension(L*W*H):

-

customized

-

Year:

-

According to the equipment configuration

-

Product name:

-

Corn Flakes Manufacturing Machine Breakfast Cereals Processing Line

-

Application:

-

Core Flakes, Breakfast Cereals

-

Function:

-

Multifunctional

-

Usage:

-

Food Industry Equipment

-

After-sales Service Provided:

-

Engineers

-

Material:

-

Stainless Steel

-

Type:

-

Fully Automatic

-

Keywords:

-

Easy Operate High Productivity

-

Power Source:

-

Electric

-

Capacity:

-

120-400 kg/h

Quick Details

-

Marketing Type:

-

New Product 2023

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Nicole

-

Voltage:

-

380V, 440V or customized

-

Power:

-

According to the equipment configuration

-

Weight:

-

3500 KG

-

Dimension(L*W*H):

-

customized

-

Year:

-

According to the equipment configuration

-

Product name:

-

Corn Flakes Manufacturing Machine Breakfast Cereals Processing Line

-

Application:

-

Core Flakes, Breakfast Cereals

-

Function:

-

Multifunctional

-

Usage:

-

Food Industry Equipment

-

After-sales Service Provided:

-

Engineers

-

Material:

-

Stainless Steel

-

Type:

-

Fully Automatic

-

Keywords:

-

Easy Operate High Productivity

-

Power Source:

-

Electric

-

Capacity:

-

120-400 kg/h

Corn Flakes Manufacturing Machine Breakfast Cereals Processing Line With Sugar Melting And Spraying Machine

Products Description

Corn Flakes Manufacturing Machine Breakfast Cereals Processing Line With Sugar Melting And Spraying Machine

This production line uses corn, wheat, oats and other grains as the main raw materials. The twin-screw extruder realizes cooking, granulation, and then tableting, baking, spraying and other processes to make crisp instant breakfast. For corn flakes, this production line has high molding rate, crispy taste, and delicate tissue structure.

The scientific production process can preserve the nutrients in the grains intact, and the entire assembly line is reasonably configured to achieve full-process control.

The scientific production process can preserve the nutrients in the grains intact, and the entire assembly line is reasonably configured to achieve full-process control.

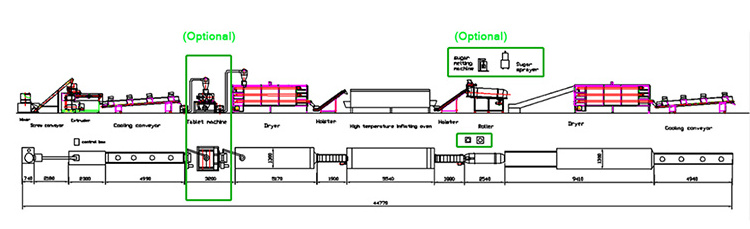

Process Flow:

Mixing -- Extrusion -- (Flaking) -- Drying -- Inflating -- (Sugar coating)-- Drying -- (Packing)

Equipment Configuration:

Mixing -- Extrusion -- (Flaking) -- Drying -- Inflating -- (Sugar coating)-- Drying -- (Packing)

Equipment Configuration:

Mixer→Screw Conveyor→Twin-screw Extruder→Cooling Conveyor→Air Conveyor→Flaking Machine

→Air Conveyor→

Dryer→Hoister→Viberating Feeder→High-Temperature Roaster Oven

→

Viberating Feeder→Dryer

→

Flavoring Line→(Packing Machine)

Product Paramenters

|

Item No.

|

Installed Power

|

Power Comsumption

|

Capacity

|

Dimension

|

|

NT-65

|

140KW

|

90KW

|

120-150kg/h

|

39*2*2.5m

|

|

NT-70

|

160KW

|

120KW

|

200kg/h

|

41*1.5*2.5m

|

|

NT-85

|

190KW

|

140KW

|

300-400kg/h

|

43*2*3.5m

|

Hot Searches