- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

Depend on capacity

-

Weight:

-

Depend on capacity

-

Item:

-

dual fuel biomass wood chips for steam hot water heater boiler

-

Design fuel:

-

coal, wood, chips, pellet, husk, etc

-

Thermal efficiency:

-

85%

-

Rated working pressure:

-

0.7/1.0/1.25/1.6/2.5Mpa

-

Rated steam temperature:

-

170/184/194/204/225C

-

Feed Water Temperature:

-

20C

-

Application:

-

rice mill, sugar mill, food and beverage, textile and Printing etc

-

Color:

-

Customer's Requirement

-

Fuel consumption:

-

151-1160 kg/h

-

Rated thermal power:

-

0.35-7 MW

Quick Details

-

Steam Production:

-

0

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

XinLi

-

Dimension(L*W*H):

-

Depend on capacity

-

Weight:

-

Depend on capacity

-

Item:

-

dual fuel biomass wood chips for steam hot water heater boiler

-

Design fuel:

-

coal, wood, chips, pellet, husk, etc

-

Thermal efficiency:

-

85%

-

Rated working pressure:

-

0.7/1.0/1.25/1.6/2.5Mpa

-

Rated steam temperature:

-

170/184/194/204/225C

-

Feed Water Temperature:

-

20C

-

Application:

-

rice mill, sugar mill, food and beverage, textile and Printing etc

-

Color:

-

Customer's Requirement

-

Fuel consumption:

-

151-1160 kg/h

-

Rated thermal power:

-

0.35-7 MW

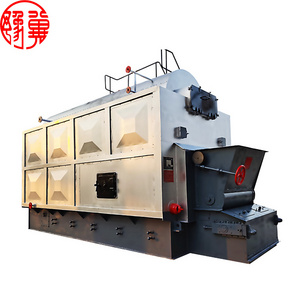

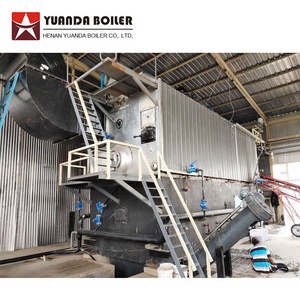

SZL DZL 2 mw 8 bar Boiler 20mw Dual Fuel Biomass Wood Chips for Steam Boiler Greenhouse Coal Fired Hot Water Heater

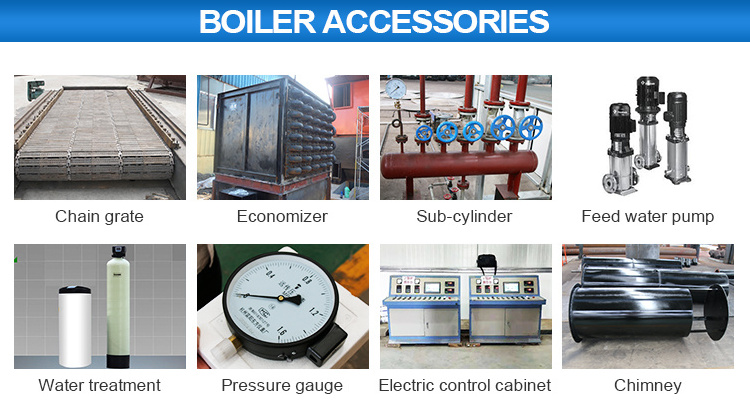

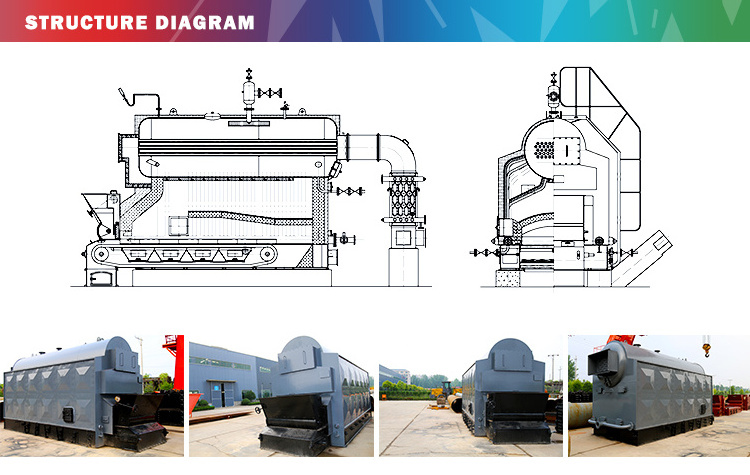

DZL Coal Biomass Hot Water Boiler is energy saving and compact structure, the pressure raise up quickly. DZL series Biomass Hot Water Boiler is single drum horizontal type shell boiler, the combustion equipment is chain grate/moving grate (small scale flaker is available), has the advantages of feed mechanically and strong adaptability of different fuels. The fuel could be wood chips, rice hull, bagasse, straw, peanut shell, mustard stalk, cotton stalk, coconut shell, and waste cloth, etc. Biomass particle diameter should be 6-10 mm, length should be 25-50mm, and water content should be less than 15%. The source of solid biomass fired hot water boiler fuel is widespread, it is renewable green energy with the advantages of low cost, environmental friendly (sulfur content<0.06%, and zero CO2 emission), energy saving, and high combustion efficiency (>90%). Sitong Boiler could design the boiler based on customers’ requirement, the grate could be designed as fixed grate, moving grate, chain grate, and reciprocal grate, etc.

Features:

1. For the fuel with high humility, increase the length of preheating section, provide effective heating source to heat or directly put into hot flue gas high temperature segment.

2. New furnace structure, bulge defects caused by the bottom of the drum being heated directly is avoided

3. Secondary air design in the chamber, supply oxygen timely, improve combustion efficiency and reduce emissions.

4. Economizer and air preheater could be arranged at the tail of biler to improve the thermal efficiency.

5. The temperature rise up quickly with high thermal efficiency (83%).

6. The 100% NDT make sure the boiler life span more than 20 years.

|

Model |

Rated power (MW) |

Rated pressure (Mpa) |

Supply water Temperature (℃) |

Return water temperature (℃) |

Thermal Efficiency (%) |

Overall dimension L×W×H (mm) |

Weight (t) |

|

DZL0.35-95/70 |

0.35 |

0.7/1.0 |

95 |

70 |

83-84 |

3.2x2.0x2.6 |

8 |

|

DZL0.7-95/70 |

0.7 |

0.7/1.0 |

95 |

70 |

5.1x2.2x3 |

12 |

|

|

DZL1.4-95/70 |

1.4 |

0.7/1.0 |

95 |

70 |

5.5x2.3x3.3 |

23 |

|

|

DZL2.8-95/70 |

2.8 |

0.7/1.0 |

95 |

70 |

6.6x2.6x3.6 |

25 |

|

|

DZL4.2-95/70 |

4.2 |

0.7/1.0 |

95 |

70 |

7.5x2.9x3.8 |

35 |

|

|

DZL5.6-95/70 |

5.6 |

0.7/1.0 |

95 |

70 |

8.1x3.1x3.8 |

45 |

|

|

DZL7.0-95/70 |

7 |

0.7/1.0 |

95 |

70 |

Upside 7.7x3.2x3.6 Underpart 8.6x3.0x2.6 |

61 | |

|

Note: 1. Parameter is for reference only, if any changes should follow the factory technical data. 2. Our company can design boiler products based on customers’ requirement and different biomass fuels. |

|||||||