- Product Details

- {{item.text}}

Quick Details

-

Power:

-

Customized

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

3900 KG

-

Name:

-

Single Effect evaporator equipment

-

Function:

-

Concentrating

-

Solvent:

-

water/alcohol/methanol

-

Heating Model:

-

steam/oil

-

Working Pressure:

-

vacuum

-

Volume:

-

50-20000L

-

System vacuum (MPa):

-

Jacket(MPa): 0.09~0.3

-

Key words:

-

double effect evaporator

-

Usage:

-

Single Effect evaporator

Quick Details

-

Place of Origin:

-

Hubei, China

-

Brand Name:

-

WTEYA

-

Voltage:

-

110V,220V,380V,440V,460V

-

Power:

-

Customized

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

3900 KG

-

Name:

-

Single Effect evaporator equipment

-

Function:

-

Concentrating

-

Solvent:

-

water/alcohol/methanol

-

Heating Model:

-

steam/oil

-

Working Pressure:

-

vacuum

-

Volume:

-

50-20000L

-

System vacuum (MPa):

-

Jacket(MPa): 0.09~0.3

-

Key words:

-

double effect evaporator

-

Usage:

-

Single Effect evaporator

Product Description

Product introduction

Single-effect evaporator is a kind of evaporation equipment that can only carry out a single heat energy conversion, and its core feature is that the secondary steam generated is no longer used for heating, but directly discharged or condensed.

Basic characteristics of single effect evaporator:

1. Single-effect evaporator is suitable for small scale, steam cost insensitive occasions, or dealing with corrosive, polluting materials.

2. In single-effect evaporation, because the secondary steam is not reused, the energy consumption is relatively high.

3. Improving evaporation efficiency can be achieved by increasing heat transfer temperature difference and total heat transfer coefficient.

Details Images

Product Paramenters

|

Single effect evaporation equipment parameter table

|

|

|

|

|

|

|||||

|

Evaporation capacity(t/h)

|

Evaporator type

|

Gross power(KW/h)

|

Steam consumption(t/h)

|

Circulating water consumption(t/h)

|

Floor area (length* width* height/m)

|

|||||

|

1

|

Forced-circulation evaporator

|

40

|

1.1

|

70

|

3*3*10

|

|||||

|

5

|

Forced-circulation evaporator

|

65

|

5.5

|

350

|

5*5*12

|

|||||

|

1

|

Falling film circulating evaporator

|

13.2

|

1.1

|

80

|

3*3*10

|

|||||

|

2.5

|

Falling film circulating evaporator

|

35

|

3

|

120

|

4*3*6

|

|||||

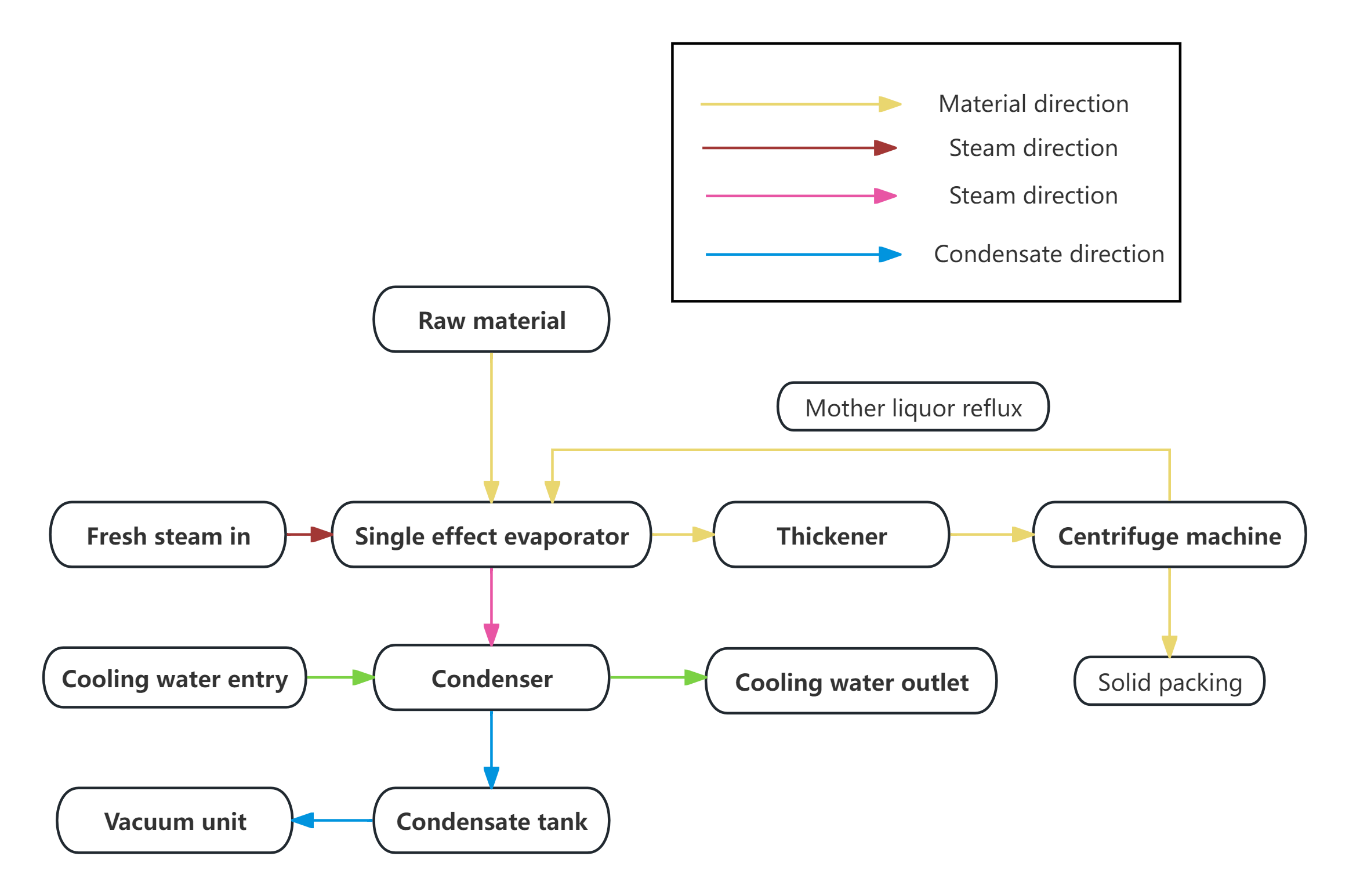

Technical principle

The working principle of the single-effect evaporator is mainly based on the evaporation and concentration process of the solution. Specifically, the following key steps are included:

1. Heating: The material that needs to be evaporated is first preheated in the preheater and then enters the heater. In a heater, the material receives heat energy, usually provided by steam, which heats the solvent (mostly water) in the solution to boiling.

2. Evaporation: When the solvent is heated to the boiling point, it begins to evaporate. In this process, the solvent is transformed into a gaseous form, and the concentration of the solute increases accordingly.

3. Separation: The gas mixture generated by evaporation (secondary steam and carried solvent vapor) enters the separator, the role of the separator is to carry out gas-liquid separation, separating the steam from the concentrated liquid.

4. Condensation: The separated secondary steam is usually sent to the condenser to be cooled into a liquid, and then treated or discharged according to demand.

5. Collection: The concentrated solution is discharged from the bottom of the evaporator and collected.

In addition, single-effect evaporators can be intermittent, semi-intermittent or continuous operation. In the batch operation, the feeding, evaporation and discharge are carried out step by step; In continuous operation, materials and products are continuously in and out.

Scope of application

Single effect evaporator application industry:

Pharmaceutical industry: Used for concentration and purification of pharmaceutical solutions.

Food industry: suitable for concentrated processing of food liquids.

Chemical industry: Used for concentration and purification of chemical solutions.

Light industry: The demand for evaporation and concentration of various liquid products.

Hot Searches