- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

SI75

-

Car Make:

-

BUS

-

Warranty:

-

1 Years

-

Product name:

-

Front Axle

-

Load Capacity:

-

7.5T

-

Braking Type:

-

DISC

-

MOQ:

-

1pcs

-

Material:

-

Customer's Requirements

-

OEM:

-

Support

-

Certificate:

-

ISO9001/TS16949

-

Application:

-

OVER 12 M COACH

-

Brake System:

-

Hydraulic

-

Weight:

-

645KG

Quick Details

-

OE NO.:

-

56236

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

DuoYuan

-

Model Number:

-

SI75

-

Car Make:

-

BUS

-

Warranty:

-

1 Years

-

Product name:

-

Front Axle

-

Load Capacity:

-

7.5T

-

Braking Type:

-

DISC

-

MOQ:

-

1pcs

-

Material:

-

Customer's Requirements

-

OEM:

-

Support

-

Certificate:

-

ISO9001/TS16949

-

Application:

-

OVER 12 M COACH

-

Brake System:

-

Hydraulic

-

Weight:

-

645KG

|

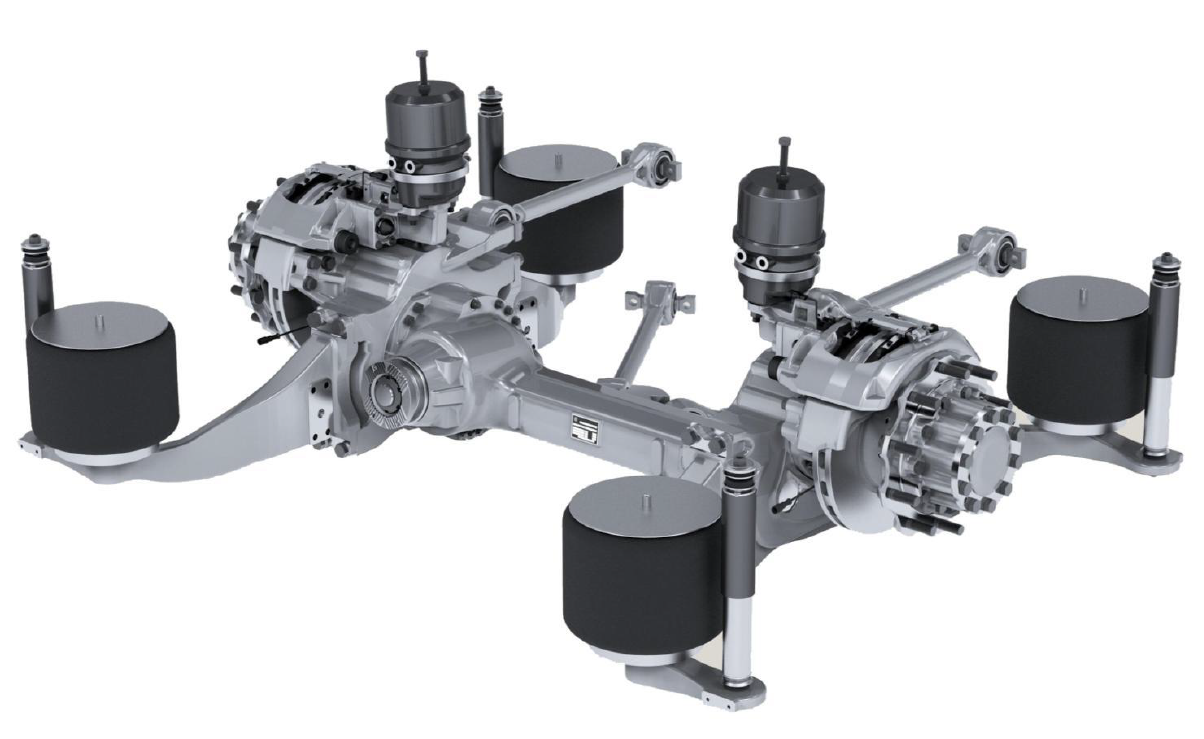

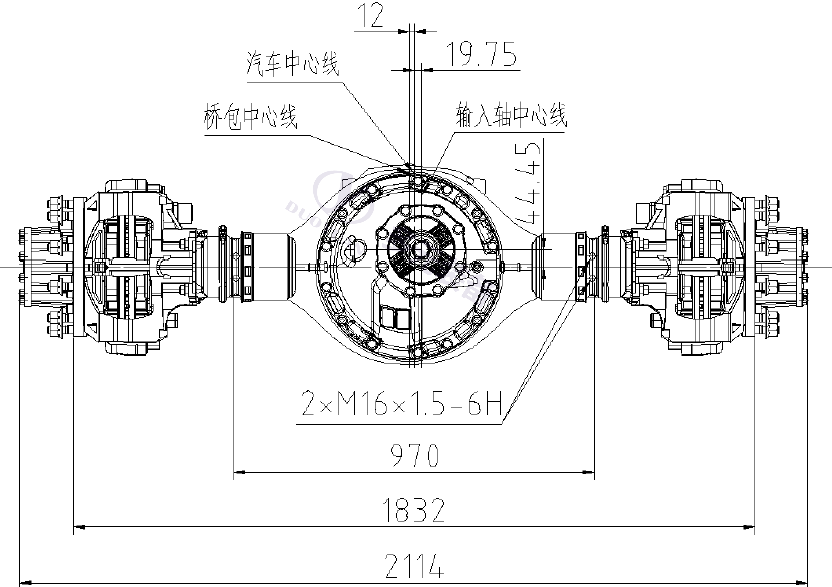

Suspension Model

|

SI75

|

|

|

|

Rated load(kg)

|

7500

|

Brake Type

|

Disc

|

|

Max. Turning Angle

|

max56°/46°

|

Tire

|

22.5”×7.5”

|

|

Axle Dynamic Travel

|

±90mm

|

Kingpin camber angle

|

7°30′

|

|

Wheel Hub Type

|

Bearing Unit

|

Wheel Inclination Angle

|

30′

|

|

Applicaition

|

over 12 m coach Bus

|

Weight(oil included)(kg)

|

645

|

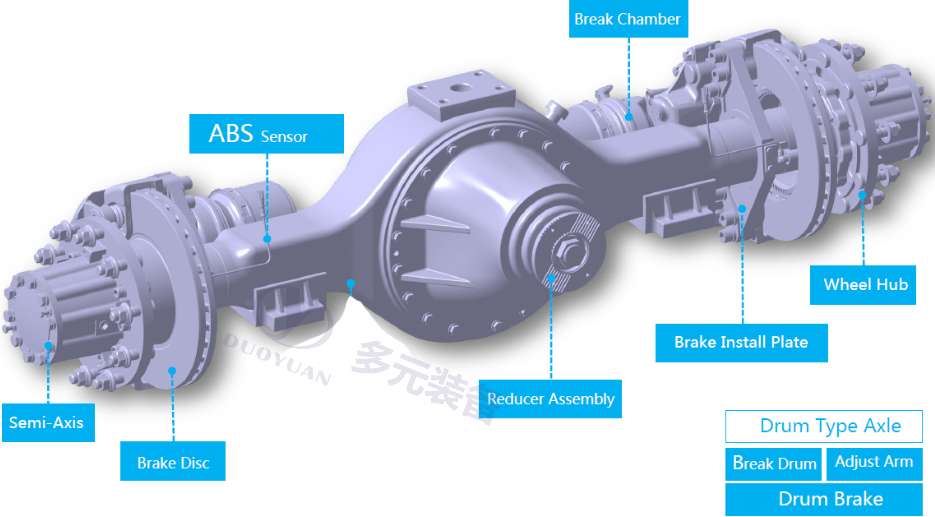

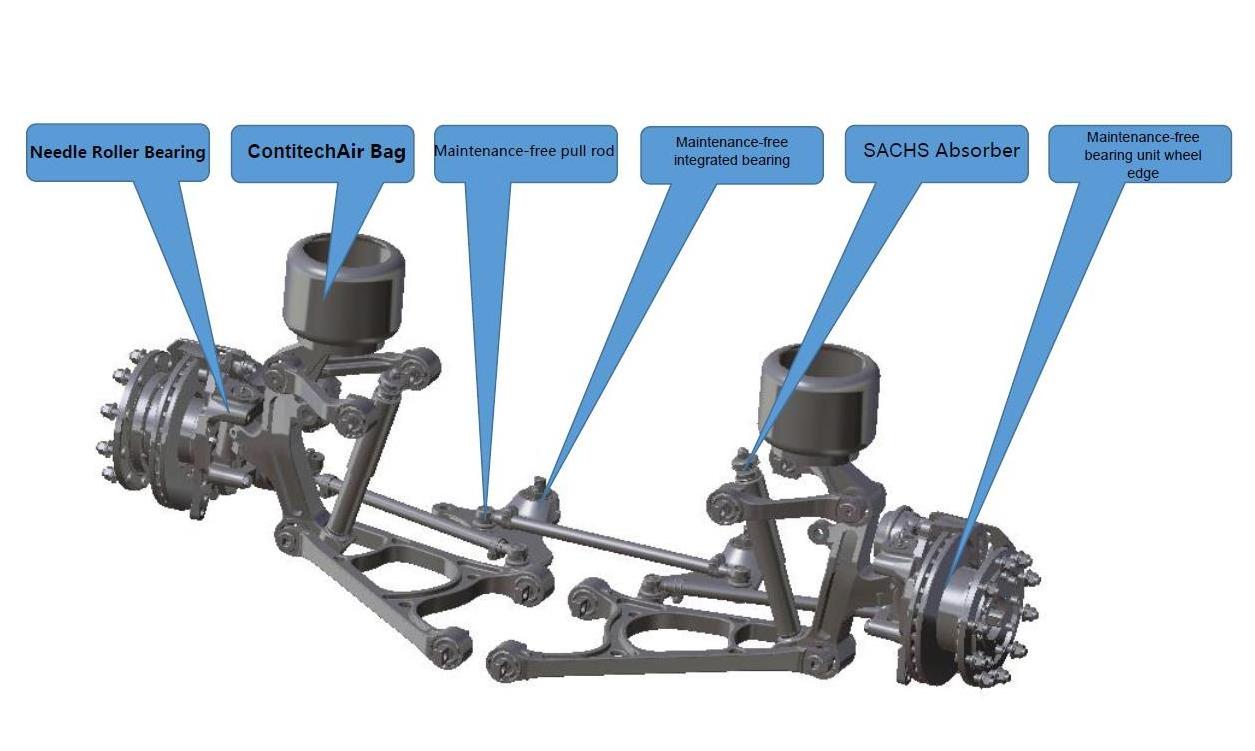

The Advantage of Our Axles and Supension

Lightweight Bus Axle Case

CAE technology is used to optimize the axle housing structure (cross-section optimization and high-strength plate application) and accessories, while the accessories are made of high-grade ductile iron to ensure the performance of the products.

Axle suspension

Lightweight

Brake

22.5 Adopt lightweight brake structure, parts use

high grade ductile iron, structure optimization,

compared with the traditional model weight reduced by 35kg~5Kg/ piece.

Axle suspension Lightweight M ain Reducer

By optimizing the structure, reducing the number of parts, making the main reduction structure more compact, reducing the number of main reduction, and increasing the transmission efficiency by 2%

Lightweight Assembly Axl e

By reducing the weight of the parts, the weight of the axle assembly is about 22KG lighter than that of the same level of the competing products

Main reduction assembly:

Mute, stronger impact resistance

1. Cooperate with international famous gear experts to design gears; Adopts the high strength gear material, increases the tooth surface width and the overlap coefficient, and makes the use of the powerful shot blasting process; Adopting imported bearings, the accuracy is improved to P4 level;

2. Gear strength is increased by about 10%;

3. According to national standard and line standard test, the main noise reduction is 3~6dB (A) lower than competing products of the same level.

Stering Knuckle needle roller bearing:

Replace the front axle knuckle bushing with needle roller bearing structure, longer maintenance and replacement life, lighter steering and better righting.

Economy of The Axle and Suspension

In order to improve the axle and suspension quality, improve customer car experience, reduce after-sales maintenance costs, fully learn from domestic and foreign advanced axle technology, especially in the axle wheel edge unique innovation, from grease lubricated wheel edge, to oil lubricated wheel edge, and then to the maintainance free axle ans suspension wheel edge, compared with the previous generation, there is a qualitative leap.

Among them, there are two kinds of maintenance-free wheel edge: oil lubrication maintenance-free (generally 500,000 km maintenance-free) and integrated maintenance-free (namely bearing unit, 5 years / 800,000 km maintenance-free).

The Axle Traditional Technology

.20,000 km maintenance cycle;

.Grease lubrication, ordinary bearings;

.Maintenance disassembly labor intensity is large;

.High maintenance cost, 8 years / 800,000 km maintenance cost of about 18103 yuan;

The AxlePrimary Technology

50,000km maintenance cycle;

Oil lubrication, ordinary bearings;

Daily maintenance wheel edge free of disassembly

The maintenance cost is greatly reduced, the maintenance cost for 8 years / 800,000 kilometers is about 3,340 yuan;

The AXLE Intermediat Technology

500,000 km /3 years maintenance cycle;

Oil lubrication, high precision bearing, automatic compensation bearing clearance;

The maintenance cost is further reduced, the maintenance cost for 3 years / 500,000 kilometers is about 2,382 yuan;

The Axle Superior Technology

800,000 km /5 years maintenance cycle;

Special high temperature resistant grease, low friction, long life, free from replacement;

Main pin with needle roller bearing, light steering, good recalibration;

The maintenance cost is close to zero (about 350 yuan for 8 years);

Test Bench on Bus Axle and Suspension

Axle and suspension Bench Test on Air Chamber Bracket

Axle and suspension

Bench Test on Three-Arm

Axle and suspension

Experimental study on

Trust rod & Bottom Plate

Bench Test on Front axle assembly

Comprehensive performance test on Suspension

Axle and suspension

Fatigue test on

Drive axle gear

Qualified Processing Line of the Axle and Suspension

Axle and Suspension Related Qualification

Partner of Axle and Suspensions

Axle and Suspension Related Customer Visit

Hot Searches